What are the common aliases for a roll forming machine?

1.What are the common aliases for a roll forming machine?

Roll forming machines, pivotal to modern manufacturing, are known by various names across industries and regions. These aliases often reflect the machine’s functionality, design nuances, or specific applications.

1.Roll Forming Machine

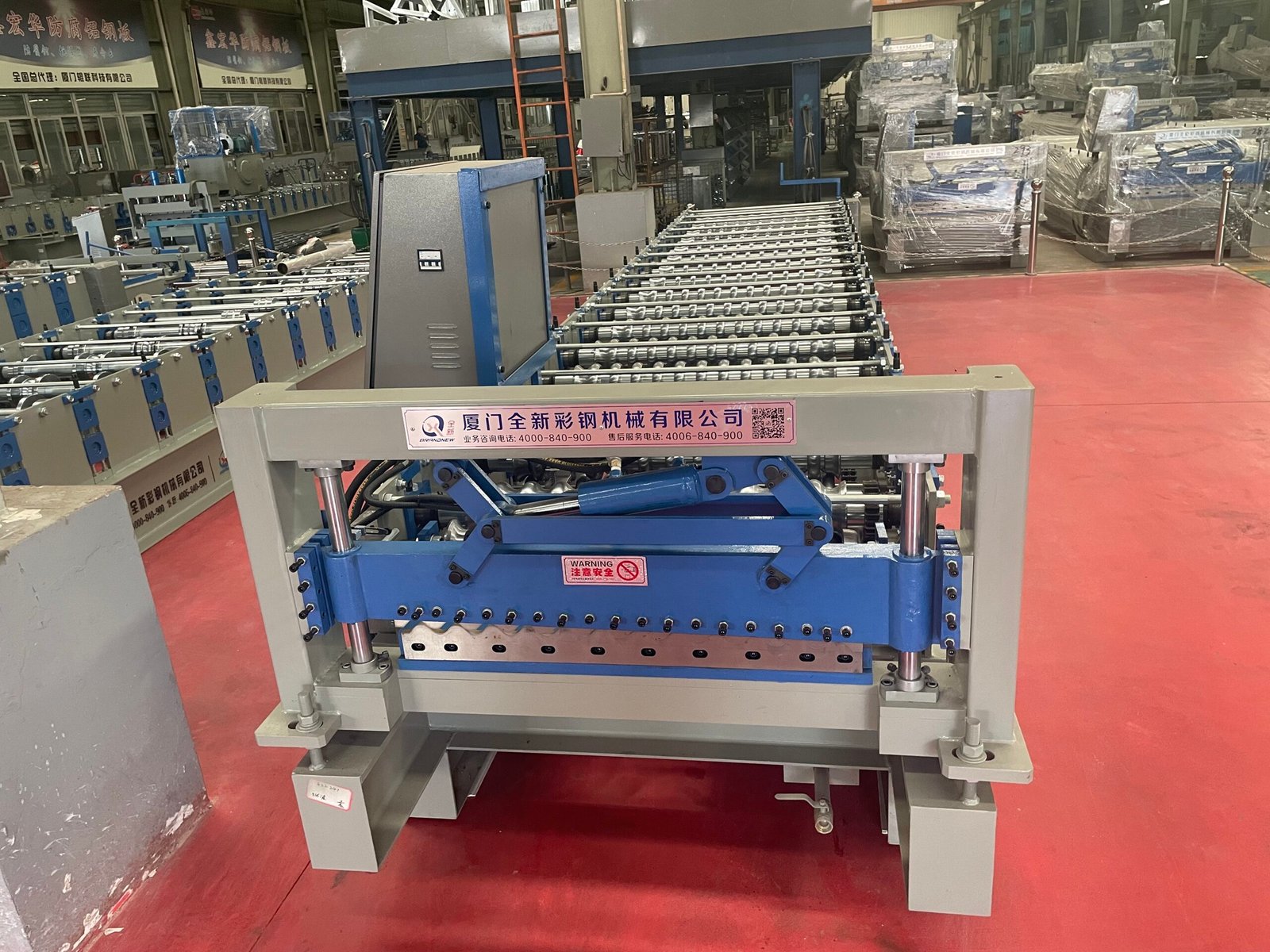

This is the most widely recognized term, emphasizing the machine’s core mechanism: shaping metal through a series of rollers. Suppliers like Xiamen Beenew Machinery Co., Ltd. use this term to describe machines that process materials such as galvanized steel into profiles like C-channels or omega beads. The term is universal but often supplemented by more specific aliases.

2.Profile Rolling Machine

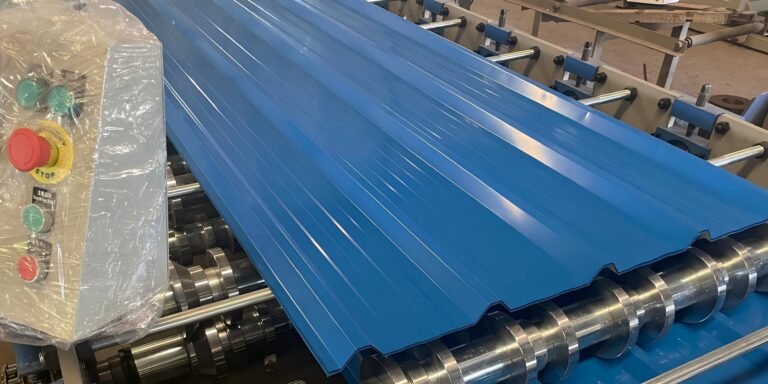

This alias highlights the machine’s ability to produce continuous metal profiles with consistent cross-sections. For instance, suppliers advertise machines for creating C/U channels, angle beads, and trapezoidal roofing sheets as “profile rolling machines”. The term is particularly common in construction and automotive industries, where standardized profiles are essential.

Example:

The C U Channel Galvanized Drywall Omega Profile Machine is marketed as a profile rolling machine capable of producing multiple structural shapes from galvanized steel coils.

3.Section Bender

In contexts where the machine focuses on bending metal into specific sections (e.g., angles, beams), the term section bender is used. This alias emphasizes the machine’s role in shaping rather than cutting or punching.

Technical Context:

Machines designed for light-gauge steel angle beads or L-bar profiles often adopt this term. For example, the L Angle Making Machine by Xiamen Beenew Machinery Co., Ltd. is described as a “section bender” for creating corner reinforcements in drywall systems.

4.Cold Roll Forming Machine

The prefix “cold” distinguishes machines that shape metal at room temperature from hot-forming processes. This alias is critical in industries requiring material integrity, such as solar panel bracket production or galvanized steel roofing.

Supplier Specifications:Beenew-Silo Roll Forming Machine processes 1.5–3.0 mm galvanized coils without heat, ensuring corrosion resistance and structural stability.

5.Continuous Roll Forming System

This term underscores the machine’s ability to operate uninterrupted, producing long metal strips or coils. It is common in high-volume manufacturing, such as rolling shutter doors or roofing panels.

Industrial Application:The High-Speed No-Stop Cutting Rolling Shutter Door Machine by Xiamen Beenew Machinery Co., Ltd. exemplifies a continuous system, achieving speeds of 10–20 meters per minute with hydraulic cutting for seamless production.

6.Metal Roll Forming Line

Used to describe a complete production setup, this alias includes auxiliary components like decoilers, hydraulic cutters, and PLC control systems. Suppliers like Botou Kefa emphasize the integration of these elements for end-to-end manufacturing.

A typical line includes:Decoiler: Unwinds metal coils (e.g., 3-ton capacity manual decoiler).

Roll forming section: 18–30 roller stations for gradual shaping.

Hydraulic cutter: Ensures precise cutting with tolerances of ±1 mm.

7.Shape Rolling Mill

Common in heavy industries, this term is often associated with large-scale machines producing structural components like I-beams or rail tracks. It derives from traditional rolling mills but incorporates modern roll forming principles.

Historical Context:Early British “roll trains” in the 19th century used sequential rollers to shape railway rails, a precursor to modern shape rolling mills.

8.Sheet Metal Profiling Machine

This alias is prevalent in industries working with thin-gauge metals, such as appliance manufacturing or HVAC systems. It emphasizes the creation of custom profiles from sheet metal.

Case Study:The Automatic Furring Channel Omega Hat Profile Machine processes 0.3–0.8 mm thick galvanized steel into furring channels for ceiling installations.

9.Structural Roll Former

Used in construction and infrastructure projects, this term highlights the machine’s role in producing load-bearing components like scaffolding or guardrails.

Supplier Example:The Scaffold Making Machine by Xiamen Beenew Machinery Co., Ltd. produces tubular steel scaffolds with 16 forming rows and 3 bending rows, ensuring structural integrity.

10.Roll Forming Press

Though less common, this term is occasionally used interchangeably with roll forming machines, particularly in older technical literature. It conflates roll forming with press braking but persists in niche contexts.

2.Regional and Industry-Specific Variations

North America:

Roll Former: A shorthand term in automotive and aerospace sectors.

Tube Mill: For machines producing cylindrical profiles.

Europe:

Profile Bending Machine: Emphasizes precision in architectural metalwork.

Section Former: Common in automotive part manufacturing.

Asia:

Steel Section Machine: Widely used in construction material industries.

Coil Forming Line: Reflects the integration of coil processing and shaping.

3.Factors Influencing Alias Usage

Material Type:Machines processing galvanized steel are often termed “galvanized roll formers”.Those handling aluminum may be called “aluminum profile machines”.

End-Product Application:

Rolling shutter door machines.

Technological Features:CNC Roll Formers: Highlight computer-controlled precision.Hydraulic Roll Formers: Emphasize cutting or bending mechanisms.

The diversity in roll forming machine aliases reflects their adaptability across industries and regions. From cold roll formers in solar panel production to continuous profiling systems for roofing sheets, these terms encapsulate the machine’s versatility. Suppliers like Xiamen Beenew Machinery Co., Ltd. tailor their terminology to align with client needs, further enriching the lexicon. Understanding these aliases is crucial for engineers, procurement specialists, and industry stakeholders to navigate global supply chains and technical documentation effectively.