Which type of standing seam roofing is suitable for your construction?

Standing seam roofing roll forming machine – Which standing seam roofing is right for your building? 2 min read The outstanding features of standing seam roofing you should know – 2 min read What is standing seam metal roof?

Do you know what standing seam roof panels are? If you don’t know, read this article now, if you do, keep reading to know more useful information about snap lock metal roofing!

What is Standing Seam Roofing?Features of Standing Seam Metal Roof

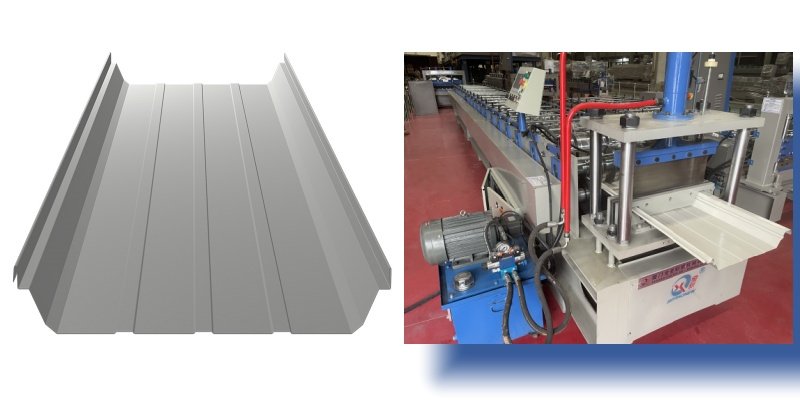

Standing seam roofing (also known as snaplock metal roofing) is a panel for roofs or walls that is lightweight, strong, durable, and uses concealed fasteners instead of screws to secure the panels.

Standing seam roof panels can be used for flat roofs or roofs with a slope, such as 1-45 degrees.

Standing seam metal roof is a roof with a good waterproof seal, and the fasteners are completely hidden, not subject to weathering like the screws used in traditional metal roofing.

If you want a metal roof panel that is easy to install, Standing seam roofing is your ideal choice because it is low cost and has a clean, aesthetically pleasing appearance.

What is Standing Seam Roofing Made of?

Standing seam metal roof is usually made of metal steel coils. The most commonly used raw materials are:

1. Galvanized steel: It is the choice of most customers at present, because it is more economical, and the material surface is galvanized so that the roof panels produced have good corrosion resistance.

2. Zincalume material: It is a combination of zinc and aluminum, and its corrosion resistance is better than galvanized steel.

3. Colorbond material: It is a steel material with various colors coated on the surface. Customers can choose the color they need according to their preferences.

4. Aluminum: It has some characteristics, such as: light weight, corrosion resistance, electrical conductivity and thermal conductivity.

5. Stainless steel: It is relatively the best material at present, and its corrosion resistance is very strong, which makes the roof panel have a long service life.

Read more: Standing seam machine

Types of Standing Seam Roofing

There are many types of standing seam metal roof, the most common ones are: YX300, YX400, YX500, etc.

These three types of standing seam metal roof are all hidden fixed profiles with unique double interlocking side overlaps. They are metal roof panels that can be installed very quickly. YX300 means that the coverage width of the profile is 300 mm. This relatively small width makes it light and more suitable for residential or light commercial roofs, and even many wall panels.

YX400 and Y500 are similar to YX300. The larger the number, the wider the width, and the coverage width is 400/500 mm. This wider panel will be installed faster, which is conducive to saving construction costs. Wide-type profiles are more suitable for commercial and industrial roof applications, and can achieve greater benefits for customers.

Advantages and applications of snap lock roof

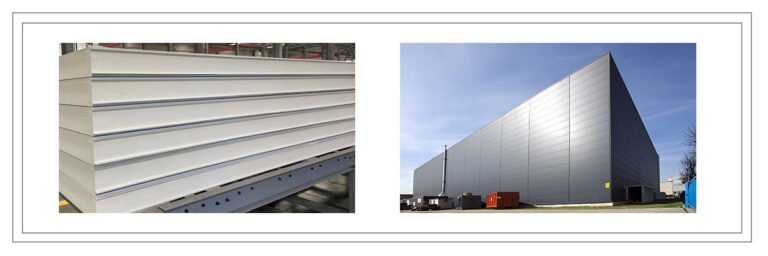

Standing seam machine is easy to install and debug, with stable production efficiency. The snap lock roofing produced can enhance the safety and stability of the structure. Due to its raw materials and roller pressing process, snap lock roof has outstanding advantages: good corrosion resistance, energy saving and environmental protection, no need for frequent maintenance, smooth surface and beautiful appearance, so it is favored by customers all over the world, especially in Europe and the United States and Russia and Ukraine.

Snap lock roof is a versatile and durable building material with a wide range of applications. The panels produced by standing seam metal roof machine are often used in roof and wall cladding materials for industrial, commercial and residential buildings.

Standing seam roof roll forming machine of Beenew machinery

There are different types of standing seam machines, and Beew machinery manufactures different types of roll forming machines. Standing seam roof is a common and popular profile that can be used in combination with corrugated panels, IBR panels, or with glazed tile panels to achieve different aesthetic effects. The panels are used as roof panels or wall panels in industrial plants, buildings, residences, and warehouses. They have beautiful appearance, corrosion resistance, and durability, and have obvious advantages.

The features of our standing seam machine are:

- Adopting inverter and PLC control, automatic roll forming and cutting

- Length setting through touch screen

- Roller and blade are made of die steel

- Electrical and hydraulic components are manufactured by internationally renowned brands

- The machine is custom designed and manufactured according to customer needs

- The production efficiency of the forming machine is stable and the failure rate is low

Read more:Standing seam machine

All of Beenew machinery’s roll forming machines are professionally manufactured in China. Our goal is to provide forming machines with the best roll forming solutions, the best design, and the best quality to bring the greatest production benefits to our customers.

Hotline:+8618959261060(WhatsApp/Wechat)

Email:vin@beenewmachinery.com

Factory:No.5, Fuming Road, Tong’an Dstrict,Xiamen City,China