When was the roll forming machine first invented?

1.When was the roll forming machine first invented?

Roll forming machines are indispensable in today’s industrial landscape, enabling the mass production of precisely shaped metal components. Yet, pinpointing their exact origin remains elusive, shrouded in the fog of early industrial history.

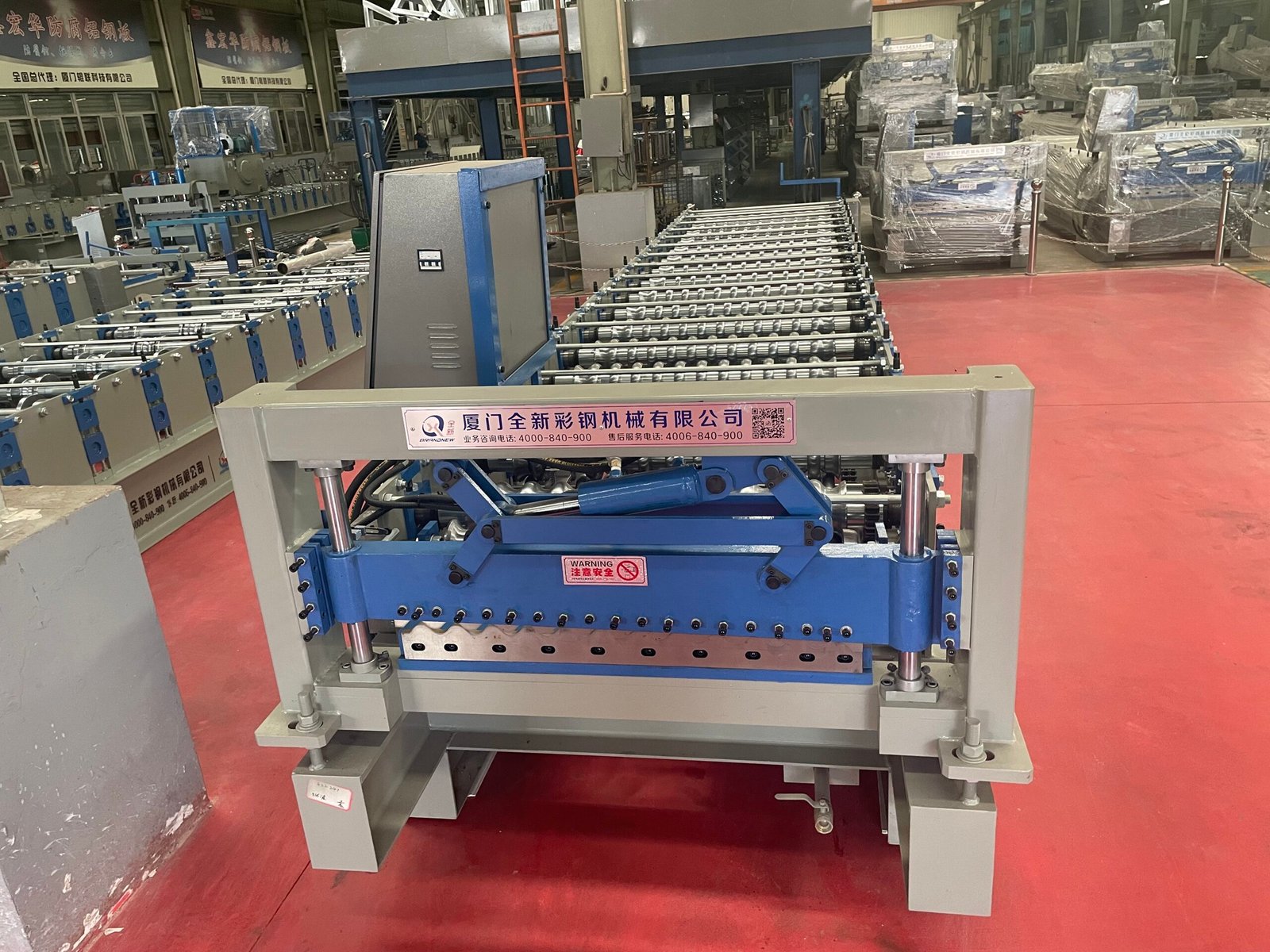

Beenew Machinery started to produce roll forming machines 30 years ago. We are one of the earliest factories to enter the roll forming machine production industry in China. We now produce more than 1,000 roll forming machines per year, including

2.Early Beginnings and Conceptual Foundations

The essence of roll forming—shaping metal through incremental deformation—can be linked to ancient metalworking practices. Early blacksmiths hammered and bent metals into tools and armor, laying the groundwork for systematic deformation techniques. While these methods lacked the sophistication of modern machinery, they embodied the core idea of gradual shaping.

The 18th and 19th centuries marked a turning point as the Industrial Revolution spurred demand for efficient manufacturing.

Factories sought ways to standardize production, particularly for metal goods like pipes and rails. This era likely saw the first crude iterations of roll forming devices, though historical records offer no definitive proof. Scholars speculate that mid-19th-century engineers experimented with roller-based systems to meet growing needs for uniformity in metal parts, especially as railroads and infrastructure projects boomed.

3.The Rise of Modern Roll Forming Technology

The 20th century propelled roll forming from rudimentary experiments to industrial prominence. Advances in metallurgy, mechanical engineering, and automation catalyzed its evolution. By the early 1900s, industries such as automotive and construction demanded high-volume production of durable, lightweight components.

Roll forming machines answered this call, enabling the fabrication of car frames, roofing panels, and structural beams with unprecedented speed and consistency.

Post-World War II industrialization solidified the technology’s role. Manufacturers began commercializing roll forming machines capable of handling diverse materials like aluminum and stainless steel. Enhanced roll designs allowed for intricate profiles, from simple channels to multi-flanged shapes, meeting the precision requirements of sectors like aerospace and appliance manufacturing.

4.Technological Leaps and Industrial Expansion

The late 20th century introduced computer numerical control (CNC), revolutionizing roll forming. CNC integration transformed machines into programmable systems, eliminating manual adjustments and enabling rapid customization. Operators could now switch between complex profiles with minimal downtime, boosting productivity.

The 1980s and 1990s saw further refinements.

Industries prioritized lightweight yet robust materials, driving innovations in roll forming for thinner gauges and advanced alloys. Aerospace applications, for instance, relied on machines to produce ultra-precise components for aircraft, while construction sectors leveraged the technology for energy-efficient building systems.

5.Contemporary Innovations and Future Directions

Today’s roll forming machines are marvels of connectivity and intelligence. Embedded sensors and IoT-enabled systems facilitate remote monitoring and predictive maintenance, minimizing operational disruptions. Artificial intelligence optimizes forming processes in real time, adjusting parameters to accommodate material variations or design tweaks.

Sustainability now shapes the industry’s trajectory. Manufacturers prioritize energy-efficient machines and eco-friendly practices, such as recycling metal waste generated during forming. Meanwhile, emerging materials—carbon-fiber composites, high-strength alloys—push engineers to redesign rolls and feeding mechanisms, ensuring compatibility with next-generation substances.

Though the exact birthdate of the roll forming machine remains debated, its impact on manufacturing is undeniable. From the forges of ancient blacksmiths to today’s smart factories, the technology has evolved in lockstep with human innovation. As industries embrace automation, sustainability, and novel materials, roll forming machines will continue to adapt, reinforcing their role as a cornerstone of modern production. Their story is not just one of gears and steel but of humanity’s relentless drive to shape the world—literally and figuratively—through ingenuity.