How to optimize the forming process of a roll forming machine?

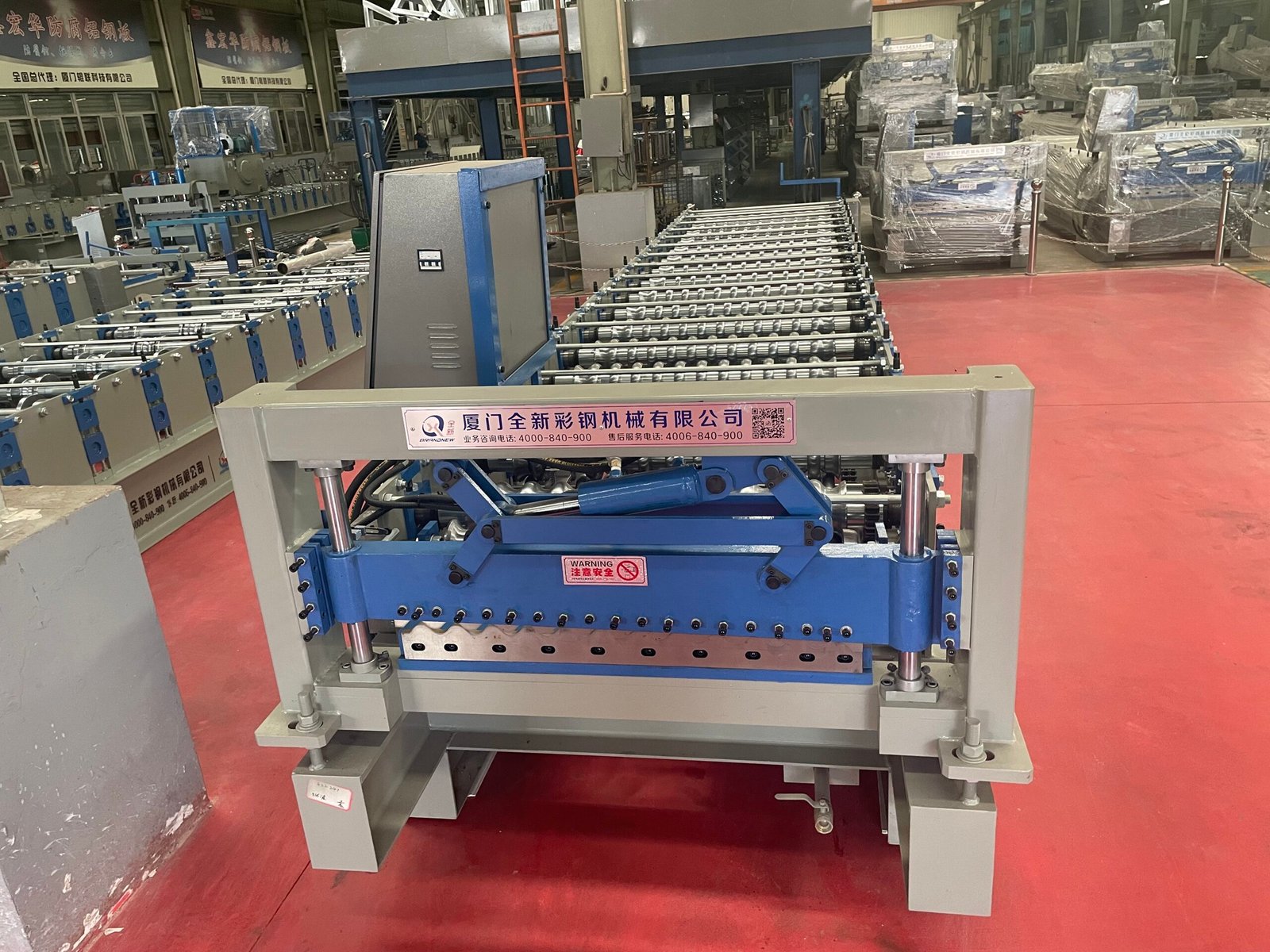

Xiamen is the high quality roll forming equipment manufacturers zone in China, Beenew machinery is always committed to manufacture kinds of size interchangeable metal purlin forming machines and other customized roll forming machines.

Optimizing Roll Forming Machine Processes

To get better results from a roll forming machine, you can Start with Good Materials,Use raw materials that have even thickness and consistent quality. Clean or coat them beforehand to reduce roller wear.

Smart Tool Setup,Design rollers with CAD/CAM software to help metal flow smoothly,Use fewer forming steps without sacrificing precision,Choose durable rollers (hardened/coated) to last longer.Fine-Tune Settings,Adjust machine speed – not too fast to cause errors, not too slow to waste time,Keep proper roller gaps and pressure to avoid bending too much or too little,Maintain steady material tension to prevent warping.Keep Things Slippery,Apply the right lubricant to cut friction between metal and rollers. This helps the machine work smoothly and stay cool.Watch Live Data,Use sensors to track important stuff like roller pressure, temperature, and alignment. Fix issues automatically as they pop up.Regular Checkups,Inspect and adjust rollers, bearings, and moving parts often. Replace worn pieces quickly to avoid flawed products.Test Before Mass Production,Run simulations with FEA software to spot problems like metal springing back or cracking. Do test runs to confirm fixes work.Train Your Team,Teach operators to handle common problems (jams, misaligned materials) and understand real-time machine data.Quality Checks,Use laser sensors or cameras to catch errors immediately. Track measurements statistically to stay within specs.

By putting these steps into action, you’ll make more products per hour, throw away fewer defective pieces, and keep quality steady.

What forming processes are there for a roll forming machine?

Roll forming machines transform materials step by step to craft accurate profiles. The process starts with preparing the material – holes or notches are often punched upfront to prevent warping that might occur if done after shaping.

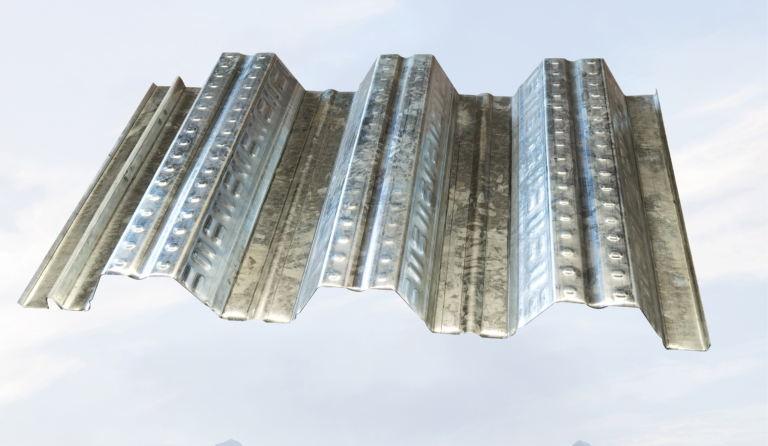

As the metal strip travels along the production line, a series of roller dies slowly bend it into the cross – section that is wanted. Different kinds of material coils can be pressed directly into the surface during this stage, adding functional grips or decorative finishes.

Sharp bends and folds are introduced using specialized rollers or side tools to form features like flanges and angles. Once the basic shape is achieved, final calibration rollers refine the dimensions, eliminating minor distortions for consistency.

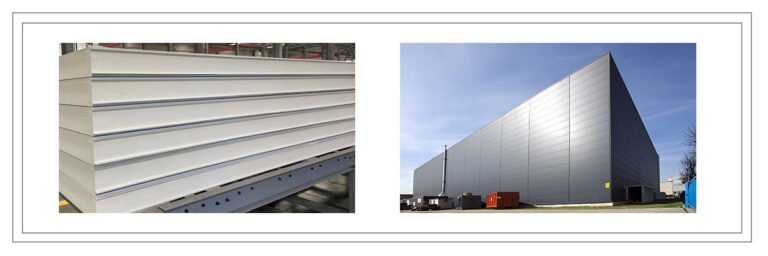

The formed profile is then cut to exact lengths using methods like rotary blades or flying saws. For complex parts, additional steps like welding or end forming may be integrated into the same production line.

Proper lubrication and controlled material tension are essential throughout to avoid surface flaws like cracks or wrinkles. The choice of rollers and production speed also depends on the material – whether it’s steel, aluminum, or other metals.

By combining these techniques, roll forming efficiently produces everything from simple U-channels, metal roofing tiles, purlins, wall cladding panels, to intricate curved components used in buildings, vehicles, and appliances.

Does a roll forming machine produce waste during the processing? How to handle it?

Yes, roll forming machines do generate waste during processing. The main types include:

Material ends/scraps from the start/end of coils or during cutting to length.

If slitting is carried out for width adjustment, edge trimmings will be produced.

Defective parts from setup adjustments or process errors.

Handling methods:

Recycling: Metal scraps (steel/aluminum) are typically collected and sold to recycling facilities.

Briquetting: Compress loose trimmings into compact blocks for easier handling and transport.

Process optimization: Use precise coil splicing, automated length measurement, and nesting software to minimize waste.

Scrap collection systems: Install conveyors or bins under the machine to catch trimmings automatically.

Regular maintenance and skilled operator adjustments also help reduce waste by preventing misalignments and material jams.