What are the characteristics of the forming rolls in a roll forming machine?

Roll forming machines are like the Swiss Army knives of metal shaping—versatile, precise, and built to handle complex tasks. At the heart of these machines are the forming rolls, the unsung heroes that turn flat metal coils into everything from gutters to car parts. Let’s break down what makes these rolls tick and why their design is so darn important.

- Material Matters: Built to Last (and Take a Beating)

Forming rolls aren’t your average hardware store bolts. They’re typically made from hardened tool steels, carbide, or specialty alloys. Why? Because they’re constantly squishing, bending, and sliding against metal sheets. Imagine rubbing sandpaper on steel for hours—these rolls need to resist wear like a champ.

For high-volume production (think automotive parts), carbide rolls are king. They’re pricier but laugh off abrasion. For smaller jobs, tool steel (like D2 or A2) works fine. Some rolls even get coatings—like chromium nitride—to add extra slickness and durability.

- Geometry: It’s All About the Curve (and the Angle)

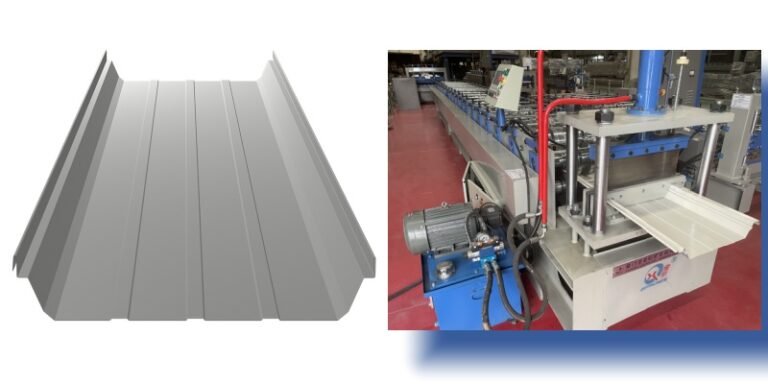

Forming rolls aren’t flat disks. Their profiles are custom-cut to match the final product’s shape. If you’re making a C-channel, the rolls have grooves that gradually bend the metal into that “C” step by step. Each roll station adds a little more bend—like a slow-motion origami master.

The roll’s radius is critical. Too tight, and you’ll crack the metal; too loose, and the bend won’t hold. Engineers also play with roll angles to control springback—that annoying tendency of metal to “bounce back” after bending.

- Surface Finish: Smooth Operator or Textured Gripper?

Ever seen a roll that looks polished like a mirror? That’s no accident. A smooth surface reduces friction, letting the metal glide without scratching. But sometimes you want grip. For materials like aluminum or coated steel, rolls might have a slight texture (like shot peening) to prevent slippage during forming.

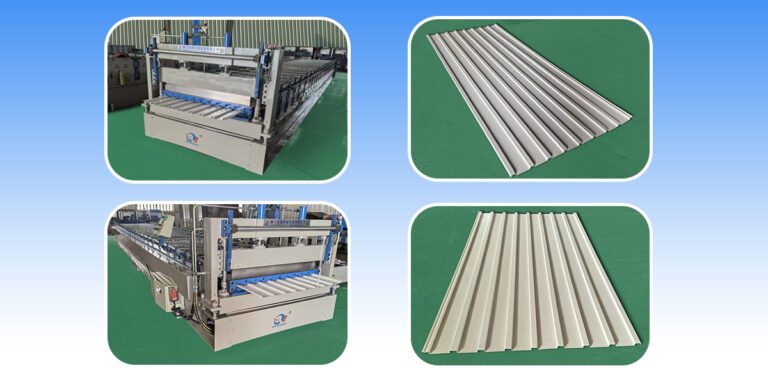

- Stack ‘Em Up: The Power of Multiple Stations

One roll doesn’t do the job. Roll forming machines use a series of roll stations (sometimes 20+ pairs!) to shape metal gradually. Each station tweaks the metal a bit more. The first few rolls might just curl the edges, while later ones lock in the final shape. It’s like a factory assembly line for bending.

- Adjustability: Because One Size Doesn’t Fit All

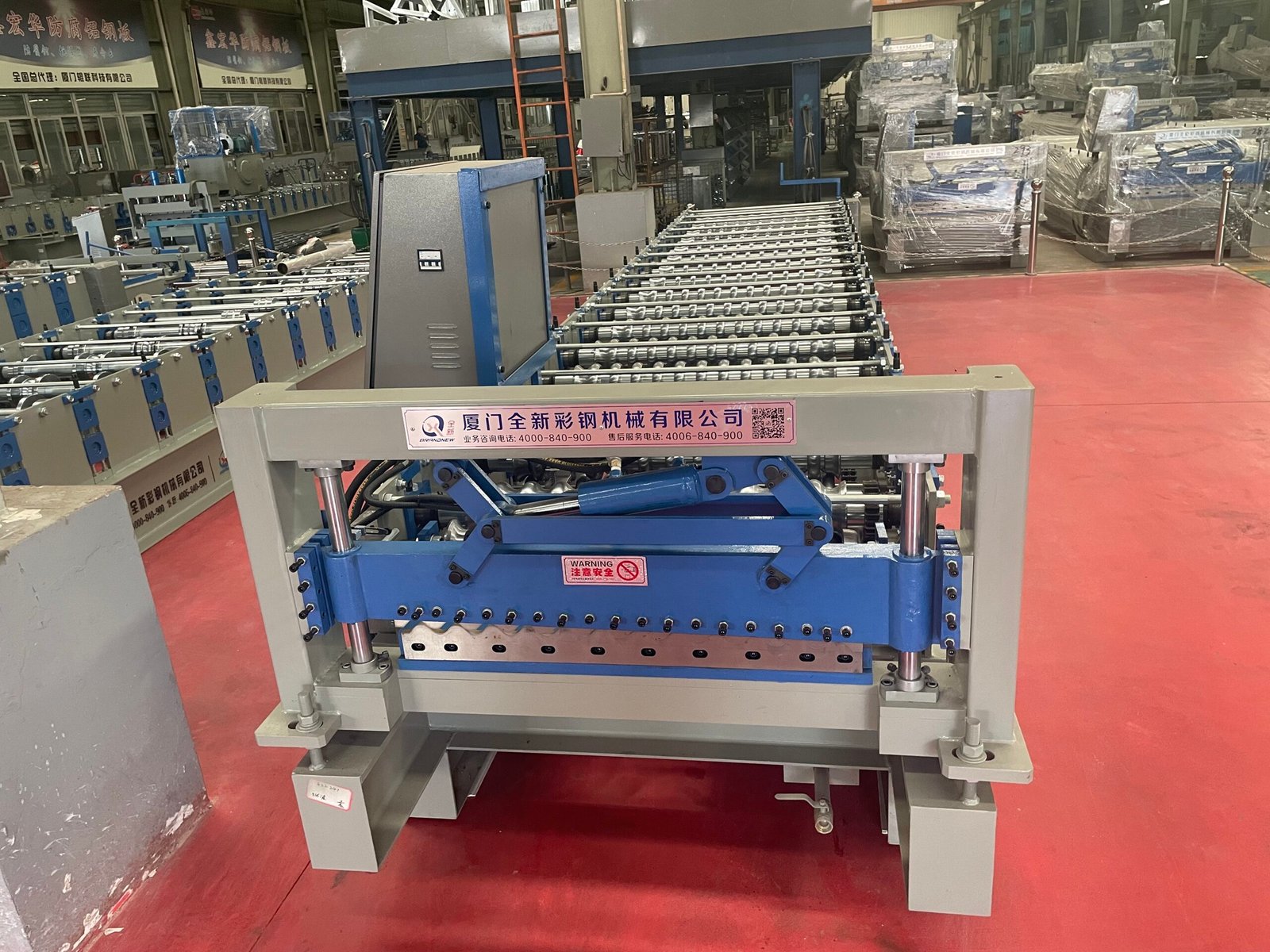

Need to switch from making roof panels to HVAC ducts? Good forming rolls are designed for quick adjustments. Some machines use shims or spacers to tweak roll positions. Others have hydraulic systems that let operators dial in settings on the fly. Time is money, and nobody wants to spend hours recalibrating.

- Heat Management: Keeping Cool Under Pressure

Friction = heat. When rolls run fast or handle thick metals, they can get hot enough to warp or even melt coatings. That’s why some rolls have internal cooling channels (like tiny water pipes) to keep temps in check. Others rely on external lubricants—think of it like rolling pins with non-stick spray.

- Maintenance: Treat ‘Em Right, and They’ll Last

Even the toughest rolls wear out eventually. Regular cleaning (metal shavings are the enemy!) and inspections for cracks or scoring are key. Some shops rotate rolls between stations to spread out wear. And when a roll finally kicks the bucket, regrinding its profile can save thousands vs. buying new ones.

- Specialty Rolls: The Oddballs of the Bunch

Pre-notch rolls: Cut slots or holes while forming—no extra step needed.

Embossing rolls: Stamp patterns into the metal (like those ridges on anti-slip ramps).

Drive rolls: Motor-powered to pull the metal through the machine.

Real-World Example: Making a Metal Roof Panel

Let’s say you’re forming a corrugated roof panel. The first set of rolls starts flattening the coil. Next, rolls gently bend the edges upward. By station 5, the classic waves start appearing. Final stations lock in the pitch and trim the edges. Each roll pair does its tiny part—no drama, just precision.

Why This All Matters

Screwing up the rolls means screwing up the product. Poorly designed rolls cause defects: wavy edges, inconsistent bends, or even torn metal. But get them right, and you’ll churn out miles of perfect parts with minimal scrap. For manufacturers, that’s the difference between profit and a dumpster full of failed prototypes.

Bottom line? Forming rolls are where engineering meets artistry. They’re not just metal disks—they’re the secret sauce that turns “meh” into “wow” in roll forming.