What are the advantages and drawbacks of sandwich panels?

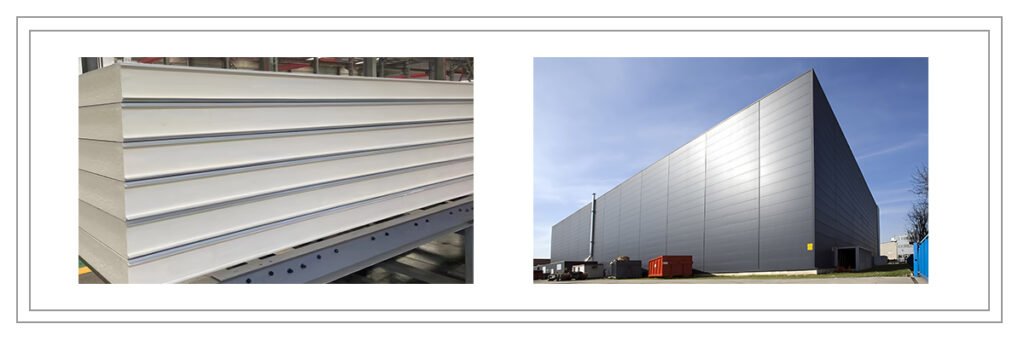

1.What is the sandwich panel?

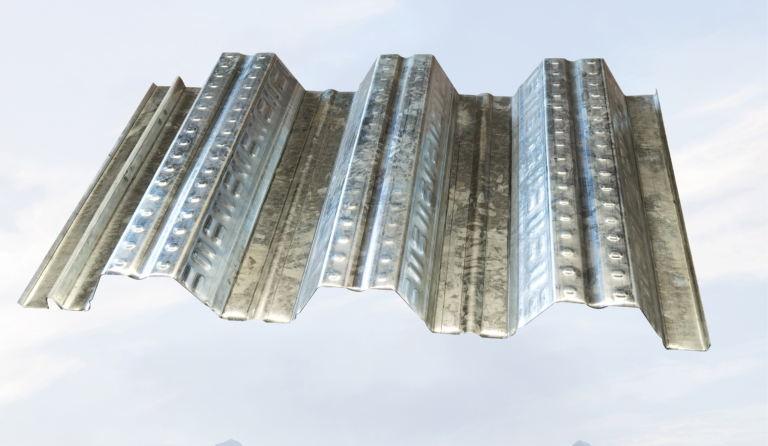

A sandwich panel is a kind of construction panel composed of three layers. There is a core material placed between two outer layers, also known as “skins”, which are generally made of metal, plastic, or composite materials. Usually, the core material is made from lightweight substances like foam, honeycomb, or balsa wood.

The unique design of the sandwich panel offers several benefits compared to traditional construction materials. It is both lightweight and strong, which makes it perfect for applications where weight is a crucial consideration. Moreover, the panel’s insulating features can contribute to enhancing energy efficiency and lowering heating and cooling expenses.

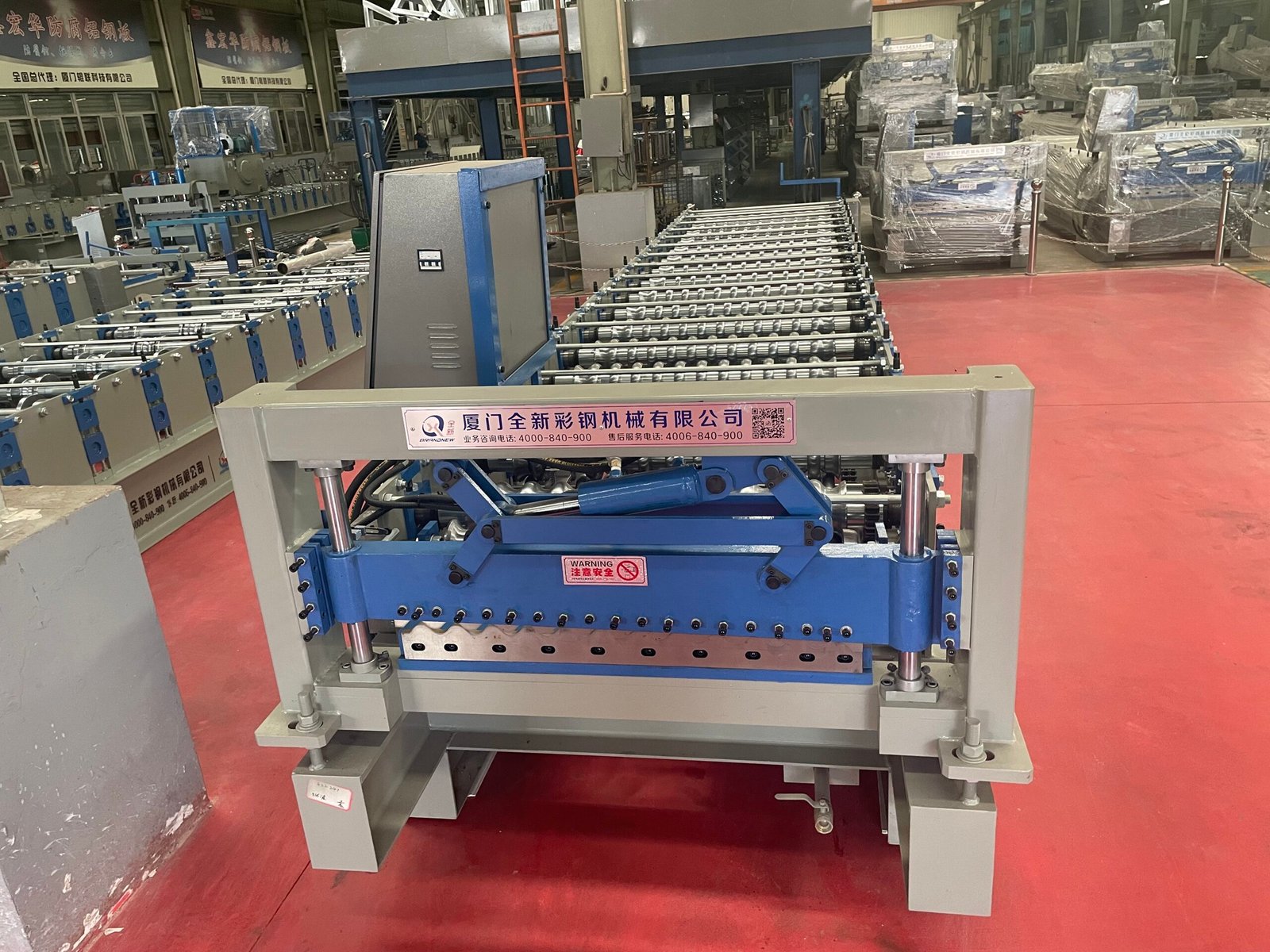

Sandwich panels manufactured by the polyurethane sandwich panel production line are frequently utilized in building construction, including the construction of walls, roofs, floors, and partitions. They are also employed in the manufacturing of vehicles, aircraft, and boats. In addition, they serve the purpose of constructing portable structures like temporary offices, shelters, and exhibition stands.

2.Application of Sandwich panels

Sandwich panels, characterized by their distinctive properties, find extensive applications across diverse industries. The following are some prevalent uses of sandwich panels:

Construction: In the building sector, sandwich panels are widely employed for constructing walls, roofs, floors, and partitions. They offer outstanding insulation capabilities and structural strength. Moreover, their assembly and disassembly processes are straightforward, facilitating construction work.

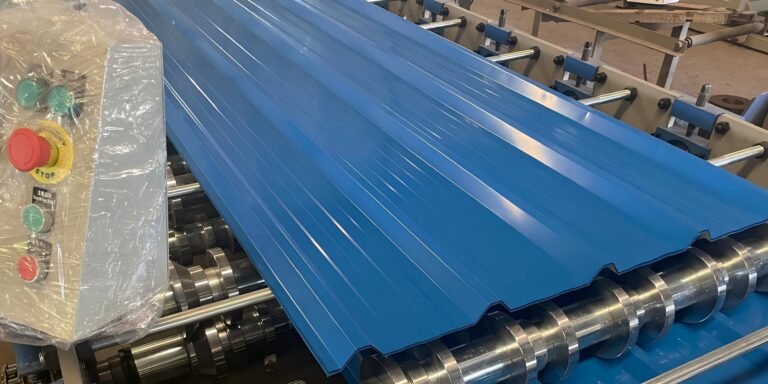

Transportation: Owing to their lightweight yet robust nature, sandwich panels are utilized in the manufacturing of vehicles, aircraft, and boats. Components like doors, floors, and walls can be fabricated using these panels, which helps in reducing the overall weight of the transportation means.

Cold Storage: Given their excellent insulation properties, sandwich panels are also applied in cold storage rooms and warehouses. These panels assist in maintaining a stable temperature and minimizing heat loss, leading to enhanced energy efficiency and cost – savings.

Cleanrooms: Industries such as pharmaceuticals, food processing, and electronics use sandwich panels in the construction of cleanrooms. They create a clean and hygienic environment that can be easily cleaned and sterilized.

Portable Structures: Sandwich panels are used to build portable structures, including temporary offices, shelters, and exhibition stands. Their easy transportability and assembly make them well – suited for outdoor events and construction sites.

3.Advantages of sandwich panel

Sandwich panels are composite structures made up of three layers with a lightweight core material placed between two thin outer skins.These panels offer a multitude of advantages, as detailed below:

Lightweight

Sandwich panels are of low weight, which simplifies handling, transportation, and installation. They are capable of being employed in the construction of edifices, walls, roofs, and floors. Reducing the structure’s overall weight helps them save on material costs.

High Strength

Despite being lightweight, sandwich panels possess remarkable strength and excellent load – bearing capabilities. They are resistant to bending, compression, and torsion, making them well – suited for high – stress applications.

Thermal Insulation

Sandwich panels have a high thermal insulation rating, making them perfect for cold rooms, freezers, and other temperature – controlled settings. They are also able to assist in reducing energy expenses by keeping the indoor temperature stable.

Fire Resistance

Often crafted from fire – resistant materials, sandwich panels are suitable for buildings that demand high levels of fire safety. They exhibit low flammability and are specifically designed and constructed to impede the propagation of fire.

Acoustic Insulation

Sandwich panels are effective at noise reduction and can be employed to create soundproof rooms or buildings. They have the ability to absorb sound waves, thereby precluding the formation of echoes.

Durability

Sandwich panels boast remarkable durability and are capable of withstanding severe weather conditions, including wind, rain, and hail. Additionally, they exhibit excellent corrosion resistance and demand only minimal maintenance.

Aesthetically Pleasing

Available in a wide variety of colors and finishes, sandwich panels are ideal for buildings that need an appealing appearance. They can be tailored to harmonize with the surrounding environment, thereby creating a distinctive and contemporary aesthetic. In general, sandwich panels manufactured by sandwich panel production lines, including those of the PU sandwich panel variety, represent an exceptional building material.They present numerous benefits compared to traditional construction methods. They are cost – effective, energy – efficient, and versatile, making them appropriate for a broad spectrum of applications.

4.Disadvantages of sandwich panel

Sandwich panels come with certain drawbacks, which are as follows:

Cost

Sandwich panels may incur higher costs compared to other building materials, particularly when custom – sized panels or specific finishes are needed.

Limited Sizes

Typically, sandwich panels are produced in standard sizes and thicknesses. This limitation can restrict design flexibility, and for unique applications, additional cutting and fitting work will be necessary.

Durability

If sandwich panels are not installed correctly or are exposed to extreme weather conditions like strong winds or heavy rainfall, they are likely to get damaged.

Fire Resistance

Some sandwich panels lack fire – resistant properties, which can present a safety hazard in buildings where fire safety is a major concern.

Moisture Resistance

Without proper sealing, sandwich panels are vulnerable to moisture penetration. This can lead to damage and have a negative impact on the panel’s insulation performance.

Recycling

Due to their composite structure, sandwich panels are difficult to recycle. This makes their disposal and end – of – life management a challenging task.

When selecting building materials, it is crucial to take these disadvantages into account. It is also advisable to collaborate with a well – informed sandwich panel machine supplier and installer to guarantee the appropriate selection and proper installation of sandwich panels.