What Makes Up a Roll Forming Machine?

1.What main components does a roll forming machine consist of?

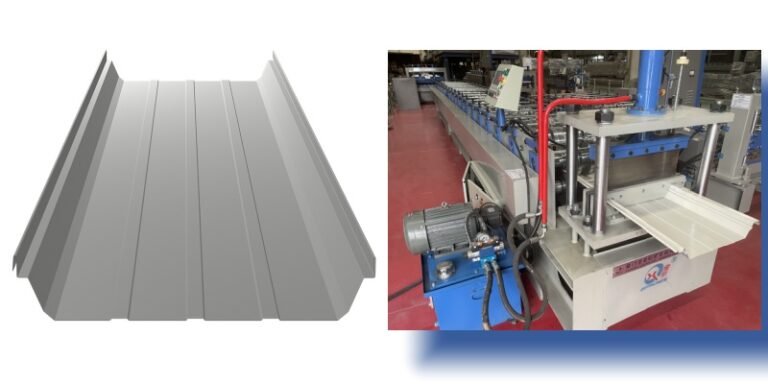

Roll forming machines are the workhorses of manufacturing. They take metal coils and shape them into all sorts of profiles—like corrugated roofing sheets, wall panels, or structural parts. Here’s a breakdown of the key parts that make these machines tick:

- The Uncoiler

Think of this as the starting point. The uncoiler holds the big metal coil and feeds it smoothly into the machine. It’s built to handle coils of different sizes and thicknesses. A tension control system keeps things steady so the metal doesn’t slip or get warped. Some even have hydraulic or electric arms that auto-adjust to keep the coil perfectly aligned. For factories running non-stop, dual uncoilers let you swap coils without shutting down the line.

- Feeding System

This part moves the metal strip from the uncoiler to the forming area. First, straightening rolls smooth out any bends or kinks in the metal. Then, servo-driven feeders push the strip forward at just the right speed, keeping everything in sync. Edge guides make sure the strip stays straight as it enters the first set of rollers—no crooked lines here!

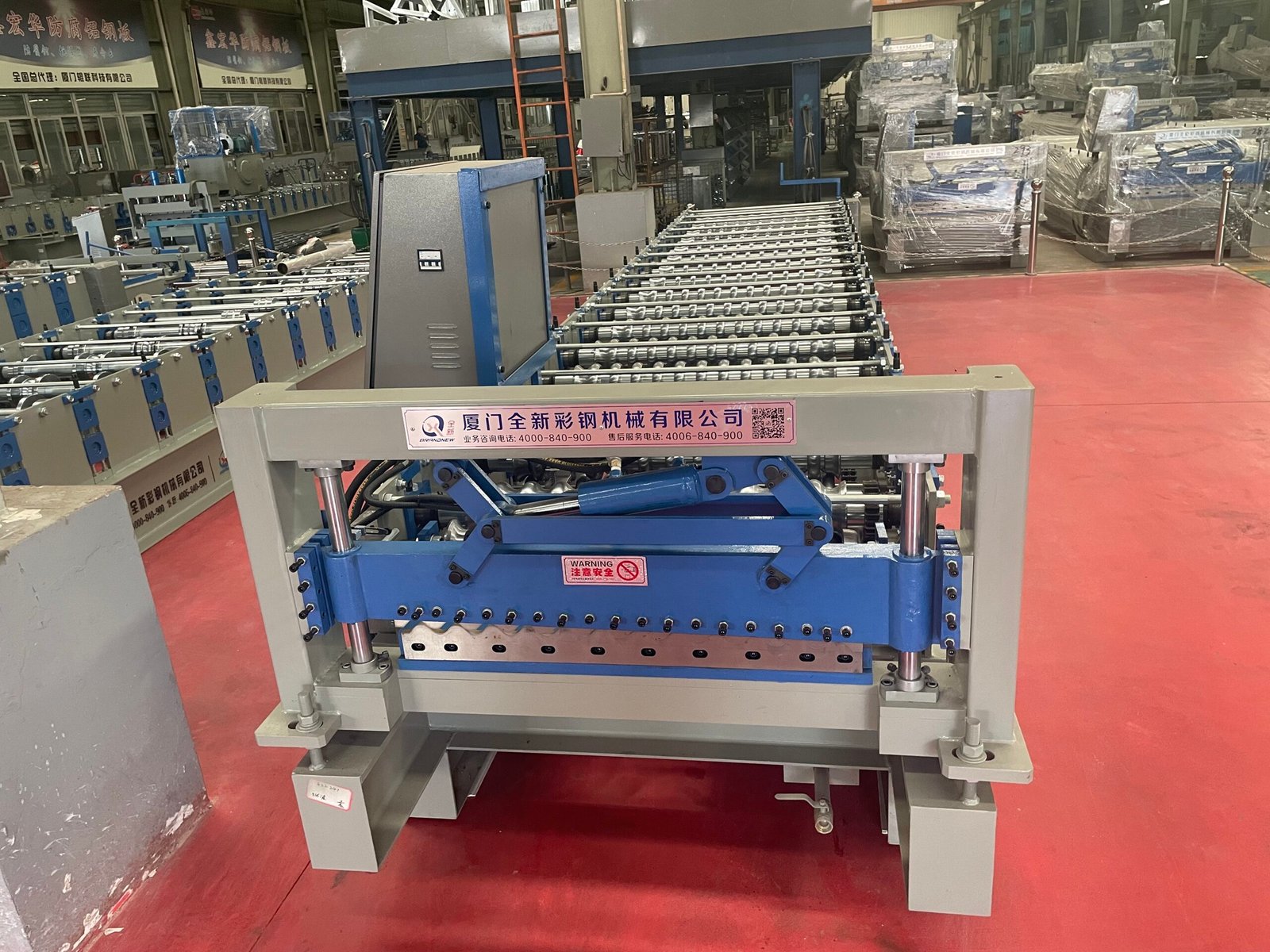

- The Roll Forming Stations

This is where the magic happens. A series of paired rollers bend the metal step-by-step into your desired shape—whether it’s a trapezoidal roof panel or a custom corrugated design. The rollers are custom-made for each profile and can be adjusted or swapped out for different materials or designs. Complex shapes might need 10–20 stations to get every detail right without stressing the metal.

- Cutting System

Once the metal is shaped, it’s time to cut it to length. Flying cut-off saws move with the metal while slicing it, so production doesn’t slow down. For thicker materials, hydraulic shears give a clean, burr-free finish. A PLC (think of it as the machine’s brain) ensures every cut is spot-on based on your settings.

- Control System

Modern machines run on smart controls. Operators use a touchscreen interface to set parameters like length, speed, or pattern. The PLC coordinates all the moving parts—rollers, feeders, cutters—while sensors watch for issues like misalignment or tension problems. If something’s off, the system adjusts or stops production to avoid waste.

- Output Conveyor

After cutting, the finished pieces ride out on a conveyor. Speed-adjustable rollers keep up with production pace, while anti-scratch surfaces protect painted or coated sheets. Automatic stackers bundle panels neatly for easy handling—no manual sorting needed.

- Extra Features (If You Need ‘Em)

Want holes or patterns in your metal? Add a punching unit. Need pre-coated sheets? Some machines can apply protective layers before shaping. Lubrication systems keep rollers running smoothly, reducing wear and tear.

2.Why Use Roll Forming Machines?

Speed & Efficiency: Churn out miles of product with minimal waste.

Consistency: Every piece matches perfectly, even in big batches.

Flexibility: Swap rollers to switch profiles fast—no downtime.

They’re a go-to for construction (roofing, walls), automotive parts, or appliances like HVAC ducts.

Picking the Right Roll Forming Machine

Material: Make sure it works with steel, aluminum, or coated metals.

Complexity: More stations = more detailed profiles.

Automation: PLC controls save time and reduce errors.

Support: Check if spare parts and tech help are easy to get.

Beenew Machinery—a top player in China with 30 years under their belt—specializes in full roll forming solutions. If you’re looking to set up a production line, we’ve got the expertise. Just shoot us a message!

A roll forming machine is like a well-oiled team—uncoiler, feeders, rollers, and cutters all working together to turn raw metal into precision parts. With tech like AI controls and modular designs, these machines keep getting smarter, meeting the demand for custom metal products in every industry.