What distinguishes sheet-metal forming from rolling?

If you’re exploring how sheet metal forming contrasts with rolling, here’s a breakdown of their distinct characteristics and applications.

Rolling: Forces metal to flow into a new shape, altering thickness and often refining grain structure.

Sheet Metal Forming: Focuses on reshaping the material through deformation, preserving thickness and grain integrity.

What distinguishes sheet-metal forming from rolling?

Sheet Metal Forming Process

Method: Conducted at room temperature (cold working) without material removal.

Mechanics: Applies force to deform the sheet, enhancing malleability for bending, stretching, or folding into intricate shapes (e.g., automotive panels, enclosures).

Contrast: Unlike rolling, forging, or extrusion, it avoids forcing material flow under high pressure.

Forming vs. Bending

Bending: A subset of forming, focusing on angular adjustments (e.g., creases, folds).

Forming: A broader fabrication category that includes bending, deep drawing, and stamping.

Temperature & Material Impact

Sheet Metal Forming: Typically room-temperature; no grain refinement.

Rolling/Forging/Extrusion: Often use elevated temperatures to improve material flow and grain structure.

Rolling Techniques

Roll Forging

Reduces cross-sectional area of heated bars/billets using counter-rotating rolls with engraved impressions.

Hot/Cold Rolling

Hot Rolling: Softens metal for easier shaping.

Cold Rolling: Enhances strength and hardness via compression (e.g., producing thin sheets or hardened steel).

Extrusion in Metalworking

Process: Pushes/pulls material (aluminum, polymers, ceramics) through a die to create specific cross-sections.

Variants:

Hot extrusion enables easier processing of high-strength alloys by minimizing material resistance.

Cold Extrusion: Ideal for ductile materials like aluminum.

Premium Roll-Forming Solutions

Discover Beenew Machinery’s advanced roll-forming systems, engineered for precision and durability. Contact their team for tailored advice or to explore machinery options suited to your production needs.

Sheet Metal Forming: Best for intricate, room-temperature shaping with minimal structural change.

Rolling: Optimized for thickness reduction, profile creation, and material strengthening.

Complementary Roles: Both processes, alongside forging and extrusion, drive versatility in modern manufacturing.

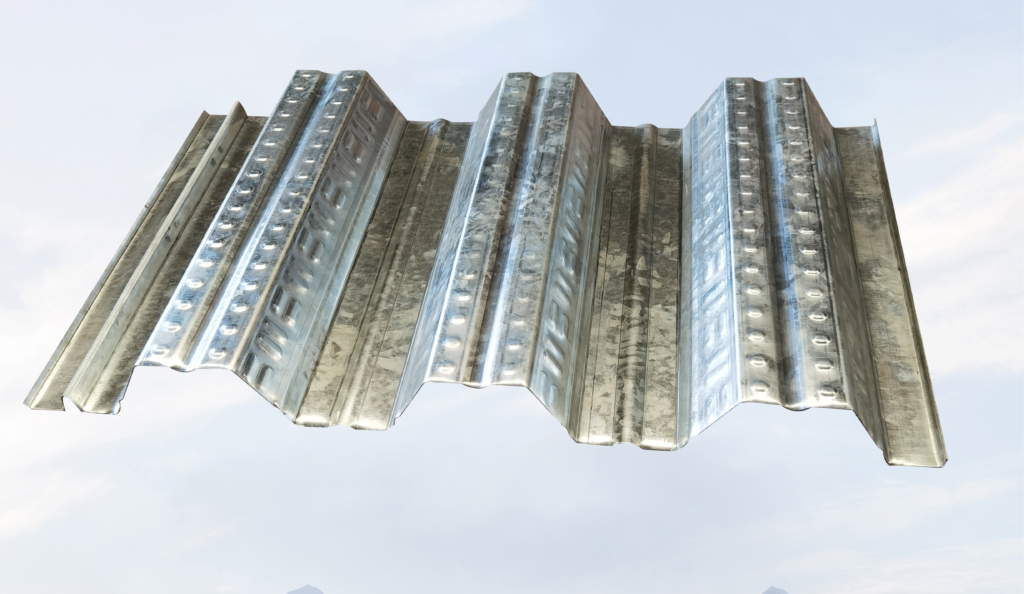

Below are some of our roofing sheet making machines

To learn more about roofing sheet making machine

VIEW our YOUTUBE CHANNEL

About Beenew Machinery

BEENEW MACHINERY is a leading roll forming machine manufacturer and forming solution provider. We can meet various needs of forming machines in the construction industry, solar photovoltaic industry, and transportation industry. With more than 28 years of experience in forming machine manufacturing, we provide high-quality forming machines and innovative forming solutions to more than 50 countries around the world and have won the reputation of customers.

BEENEW roll forming machine manufacturer and supplier is located in Xiamen, China (one of the forming machine manufacturing bases in China). The factory has a full set of machines and equipment for producing roll forming machines for the production of forming machine parts.

All of Beenew machinery’s roll forming machines are professionally manufactured in China. Our goal is to provide forming machines with the best roll forming solutions, the best design, and the best quality to bring the greatest production benefits to our customers.

Hotline:+8618959261060(WhatsApp/Wechat)

Email:vin@beenewmachinery.com

Factory:No.5, Fuming Road, Tong’an Dstrict,Xiamen City,China