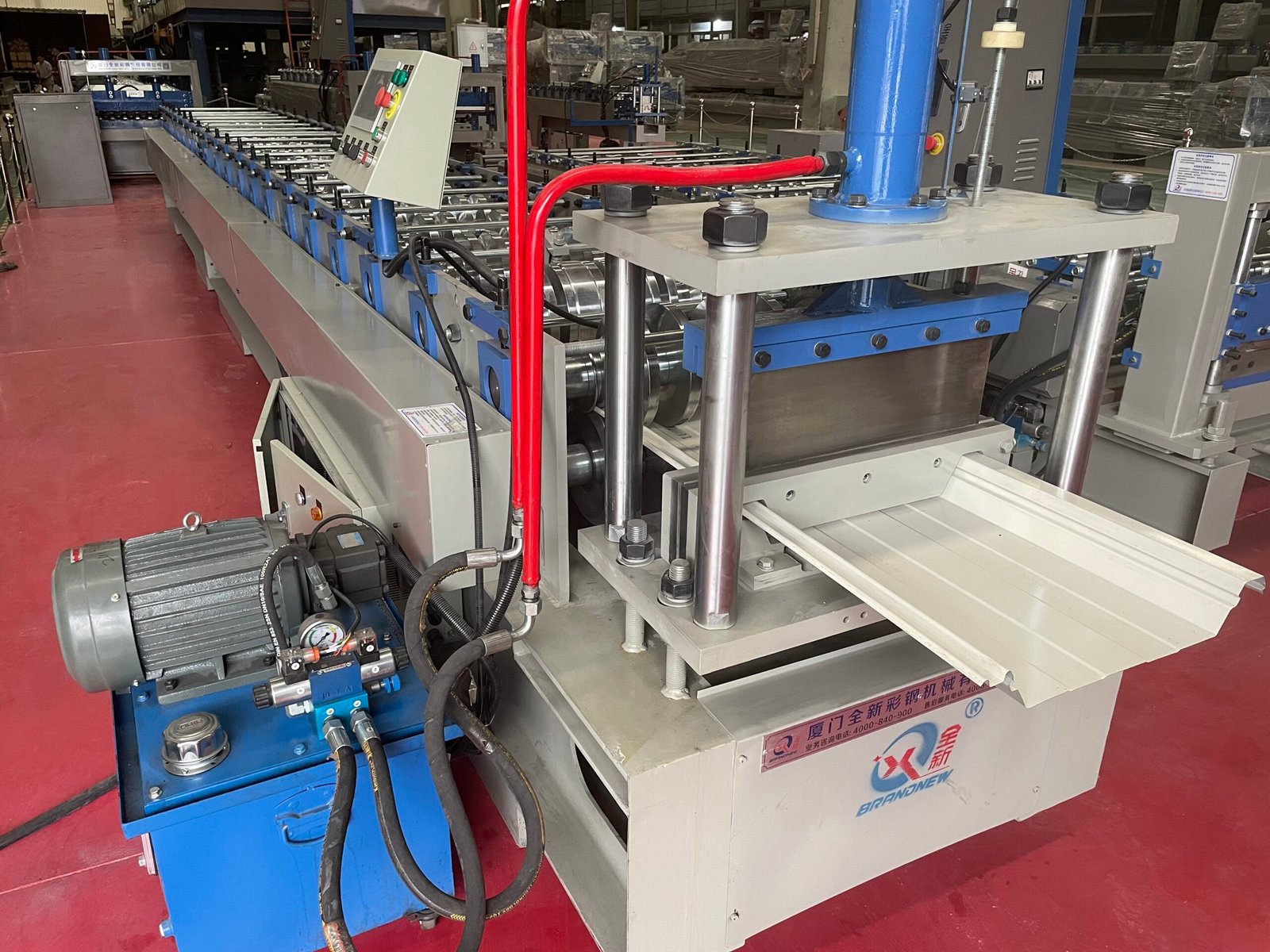

CZ Purlin Machine

CZ Purlin Machine

CZ purlin machine

With the ongoing evolution of roll forming systems, new-generation automatic quick-change purlin machines have revolutionized structural steel fabrication. These advanced systems feature intelligent modular tooling that enables seamless transitions between C, Z, and U purlin profiles within minutes through PLC-controlled hydraulic adjustments. Integrated with touchscreen interfaces and servo-driven positioning, operators can digitally reconfigure flange widths (50-300mm), lip angles (90°-150°), and material thicknesses (0.8-3.5mm) while maintaining ±0.3mm dimensional consistency.

The multi-profile interoperability eliminates traditional mold-swapping downtime, achieving 85% faster product changeovers compared to conventional systems. Real-time monitoring of roll pressure and feed speed ensures optimal material flow for both galvanized steel and high-tensile alloys. This flexibility allows single-line production of tapered purlins for curved roofing, variable-depth sections for seismic zones, and custom perforated designs for MEP integration—all while operating at 25-35m/min throughput rates. By merging adaptive automation with cloud-based parameter libraries, manufacturers now achieve 24/7 mixed-batch production with <0.5% material waste, effectively serving commercial, industrial, and prefab construction markets through one reconfigurable platform.

In structural steel manufacturing, standardized nomenclature streamlines the specification of profiles across technical drawings and project specifications. Channel sections with flange stiffeners are universally designated as C purlins, while unstiffened variants adopt the U-section classification. Modern building systems extensively employ cold-formed secondary framing components – Z-purlins for roof load distribution, C-girts for wall bracing, and specialized G-section profiles for hybrid structural connections.

Beenew machinery’ multi-profile roll forming systems redefine production flexibility through:

Interchangeable tooling cassettes enabling rapid transitions between Z200-Z450, C80-C350, and G100-G300 profiles

CNC-guided punching units achieving ±0.2mm positional accuracy for pre-punched service holes

Adaptive servo-controlled flange formers accommodating 0.6-4.0mm galvanized/G550 steel

Integrated laser measurement ensuring consistent web depths (100-600mm range)

This technical versatility supports simultaneous production of tapered purlins for arched structures, variable-flange sections for wind uplift resistance, and custom notched profiles for composite construction – all executed at 18-30 cycles/minute with automatic bundle stacking. By integrating parametric BIM data directly into machine controls, Beenew machinery systems achieve 98% material utilization efficiency, establishing new benchmarks for lean manufacturing in pre-engineered metal buildings.

Related Products

Request A Quote

If you have any questions or require more detailed information about our roll forming solutions, please contact us by clicking on the link below.

Our product specialists will be in touch with you shortly to discuss your requirements!