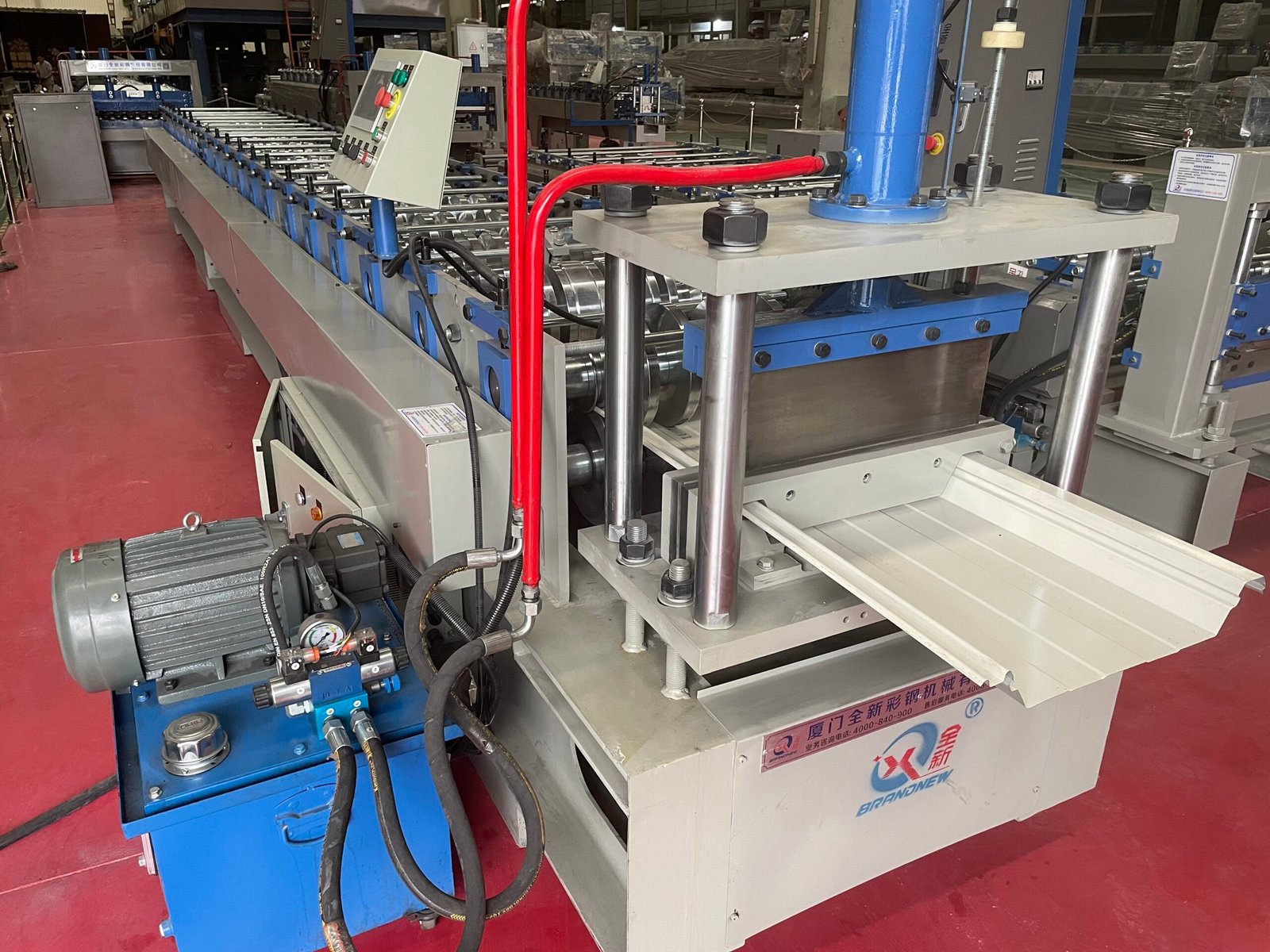

Standing Seam Metal Roof Machine

Standing Seam Metal Roof Machine

Standing seam machine

Beenew standing seam roll forming machine is available in multiple configurations, compatible with diverse roofing profiles such as corrugated sheets, IBR panels, glazed tile sheets, and self-lock roofing systems. These machines produce sheets widely utilized in industrial facilities, civilian buildings, and auxiliary roofing components (e.g., trim, fascia). Key advantages include sleek aesthetics, long-lasting durability, and weather-resistant performance.

Material

1 ) Suitable Raw Materials: Alu-zinc steel coil,color/Aluminium Coil

2 ) Suitable Coil Thickness: 0.6-1.2mm

3 ) Yield strength of raw material: 235-355Mpa

Main Components

1. Manual decoiler

1)De-coiler: Manual de-coiler

2. Roll Forming Machine

1)The main frame is 400H beams,welded separately, and the surface is sandblasted and painted to prevent rust

2)Roller Material is high grade No.45 forged steel

3)The rollers are processed by grinding machines for high precision

4)The roller is processed by precision machine tools, the surface is hard plated, and the service life is long

5)Shaft diameter is 90mm/ 85mm

6)Quantity of profile forming rollers : 16 stations

7)Chain, gear transmission, motor drive, all working actions are automatically controlled by PLC electric control cabinet

8)Main machine motor power: 7.5KW

9)Line working speed (Forming speed): 10-15m/min (without cut time)

10)Power voltage: 380V/50Hz, 3 phase (can de customized)

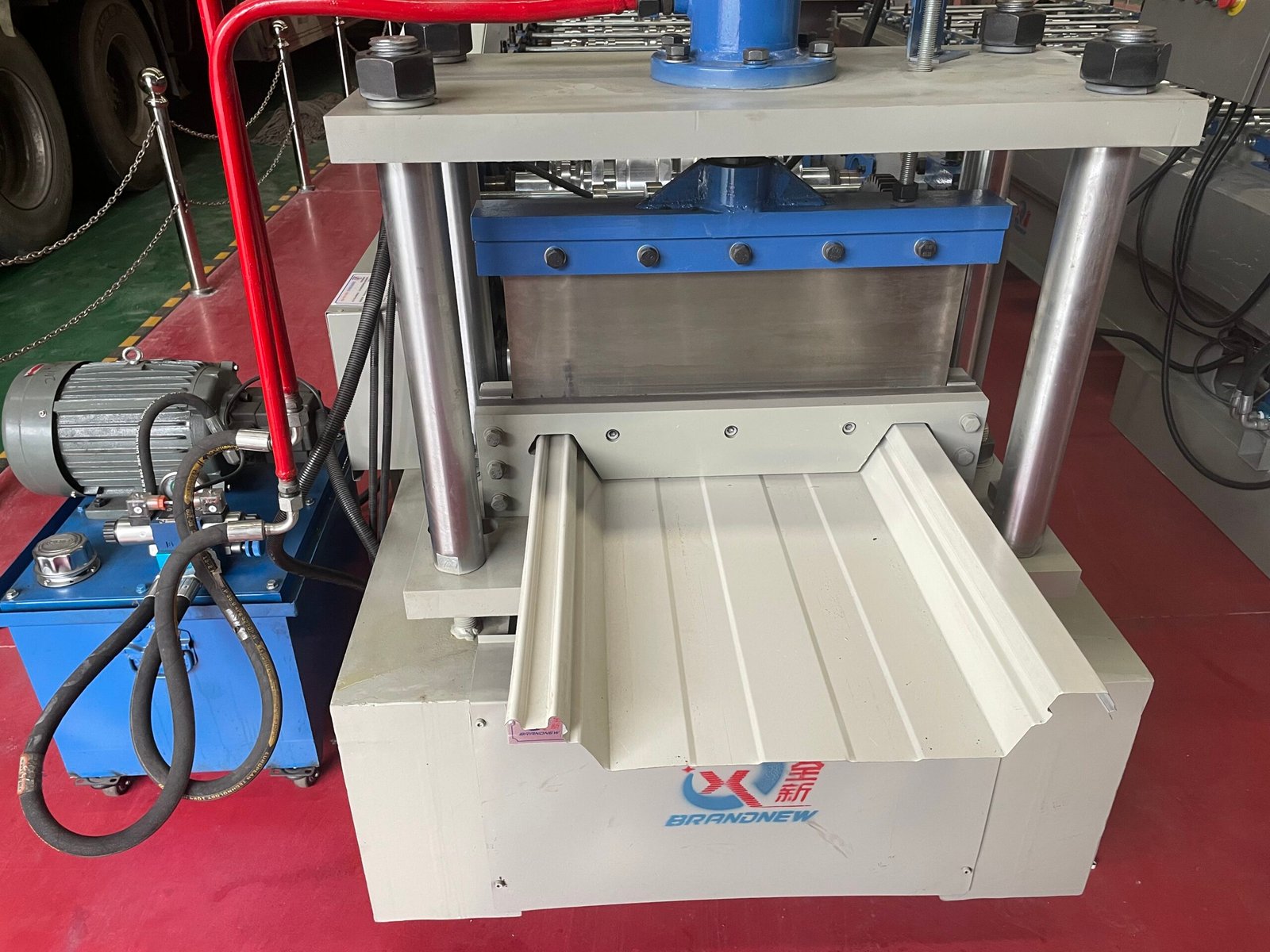

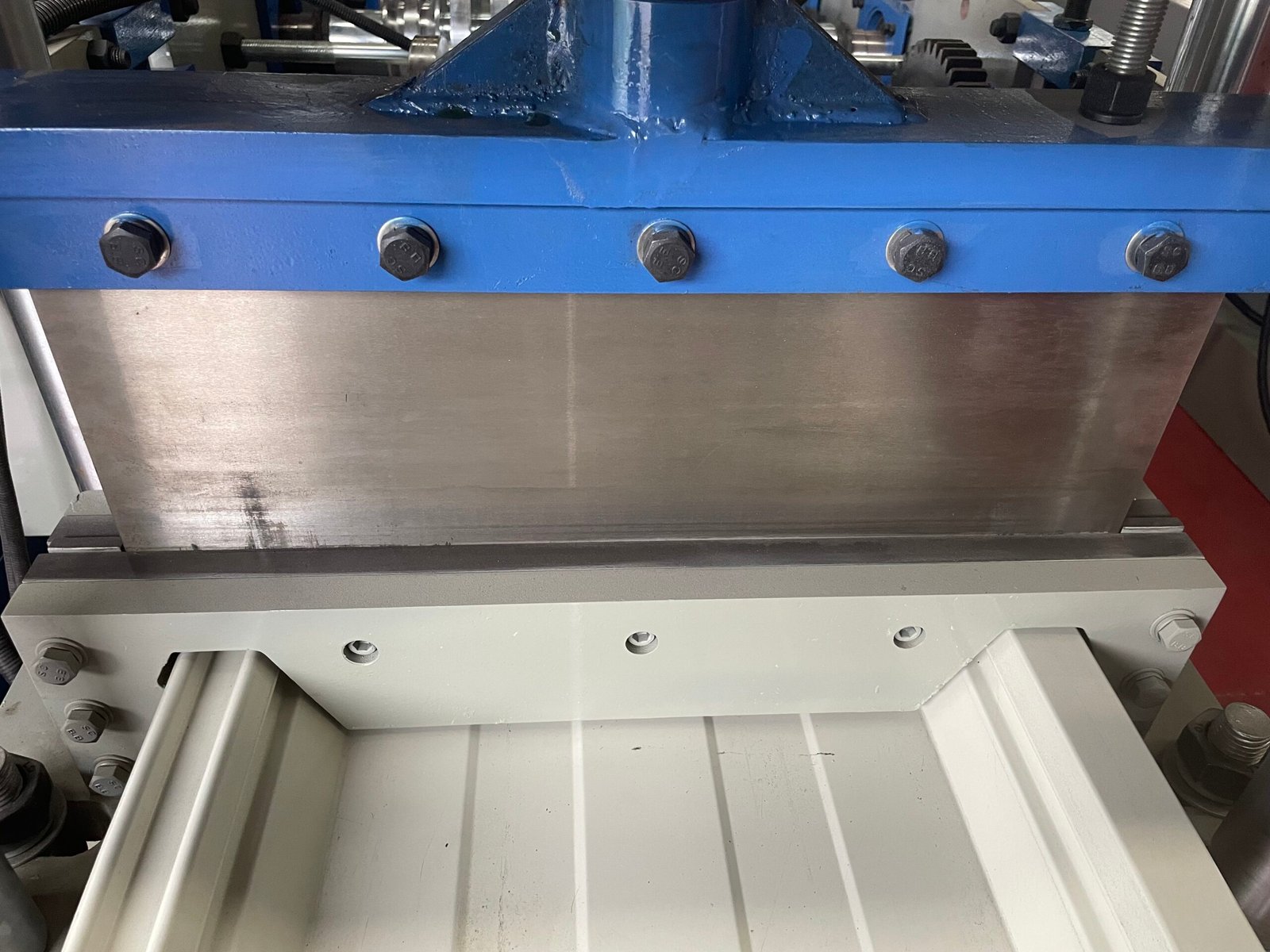

3. Hydraulic Post Cutting

1) Post cutting, Stop when cutting

2) Cutter blade material is Cr12 with quenched treatment 58℃-60℃

2) Welded frame for good rigidity

4) Cutter frame has been heat treatment to avoid final product deformation,Cutting length tolerance ±2mm

4. Hydraulic station

1) It powers the hydraulic cutter

2) All hydraulic parts are made of domestic or imported famous brand products

3) Hydraulic station, oil pump power 5.5 KW

5. Product track

Unpowered, 3 units in total, equipped with rollers on the top for easy movement

After-Sales Service for Standing Seam Roll Former

Installation & Training:

a. On-site training during factory visits (machine installation, operation, and worker upskilling included);

b. Remote support via manuals/video guides if no visit;

c. Technician dispatch available (client covers room and board).

After-Sales Service:

a. 2 years guarantee for the machine;

b. 24/7 technical assistance via email/phone;

c. Free repairs for all malfunctions during the warranty period.

FAQ

Q: Are you a trading company or a manufacturer?

A: We are a direct manufacturer with a dedicated production team and export-focused service expertise in cold roll forming machinery.

Q: Can the machine produce only one panel profile?

A: No. Our machines are engineered for multi-profile versatility, supporting wider and dual-layer production capabilities. A single unit can produce 3+ distinct panel profiles with tooling adjustments.

Q: What is the typical lead time for machine production?

A: Standard lead time is 20–45 business days. For urgent orders, we prioritize production to expedite delivery without compromising quality.

Q: How is quality control ensured during manufacturing?

A: Our rigorous QC protocol includes raw material inspection,precision machining of rolls and critical components.

Assembly verification,surface and shaft integrity testing,pre-shipment operational trials and packaging checks.

Q: What if the machine malfunctions?

A:24-month warranty,Free replacement of irreparable parts (customer covers shipping fees).

Post-warranty support: Lifetime technical assistance and negotiated repair solutions.

Q: What differentiates you from competitors?

A: Our strengths include customer-centric service with tailored engineering solutions.

Low-maintenance, user-friendly designs for quick installation and operation.

Value-added guidance to optimize your ROI and product performance.

Q: Can we partner as your international agent?

A: Absolutely! We actively seek collaborations with distributors or agents to sale our roll forming machine.

No. | Main Parameters | Roll Forming M/C Parameters | ||

1. | Material Thickness | 0.6-1.2mm | Forming Stations | 16-step |

2. | Feeding Width | According to the drawing | Body Frame | H400 |

3. | Application Material | Galvanized sheet/Cold rolled sheet | Side Wall Thickness | 20mm |

4. | Electrical Standard | 380V/50Hz/3Ph | Shaft Diameter | 45# Steel, φ90/85mm |

5. | Manual Decoiler Diameter | 5T-600mm | Main Motor Power | 7.5 KW |

6. | Yield Strength | G235-355Mpa | Screw Bolts | Grade 8.8 |

7. | Forming Speed | 15-20m/min | Effective Width | As customer design |

8. | Control System | PLC Control System | Roller | 45#forging steel with chromium plate |

9. | Hydraulic Motor | 5.5KW | Machine Color | Blue+gray(or customized) |

10. | Testing Material | Beenew will supply the dimensions of the feeding material for procurement two weeks prior to the machine testing. | ||

Related Products

Request A Quote

If you have any questions or require more detailed information about our roll forming solutions, please contact us by clicking on the link below.

Our product specialists will be in touch with you shortly to discuss your requirements!