Solar channel roll forming machine

Solar channel roll forming machine

Solar channel roll forming machine

Beenew Machinery’s Solar C&U Channel Roll-Forming Line: An Intelligent Manufacturing Solution for High-Precision Photovoltaic Structural Profiles

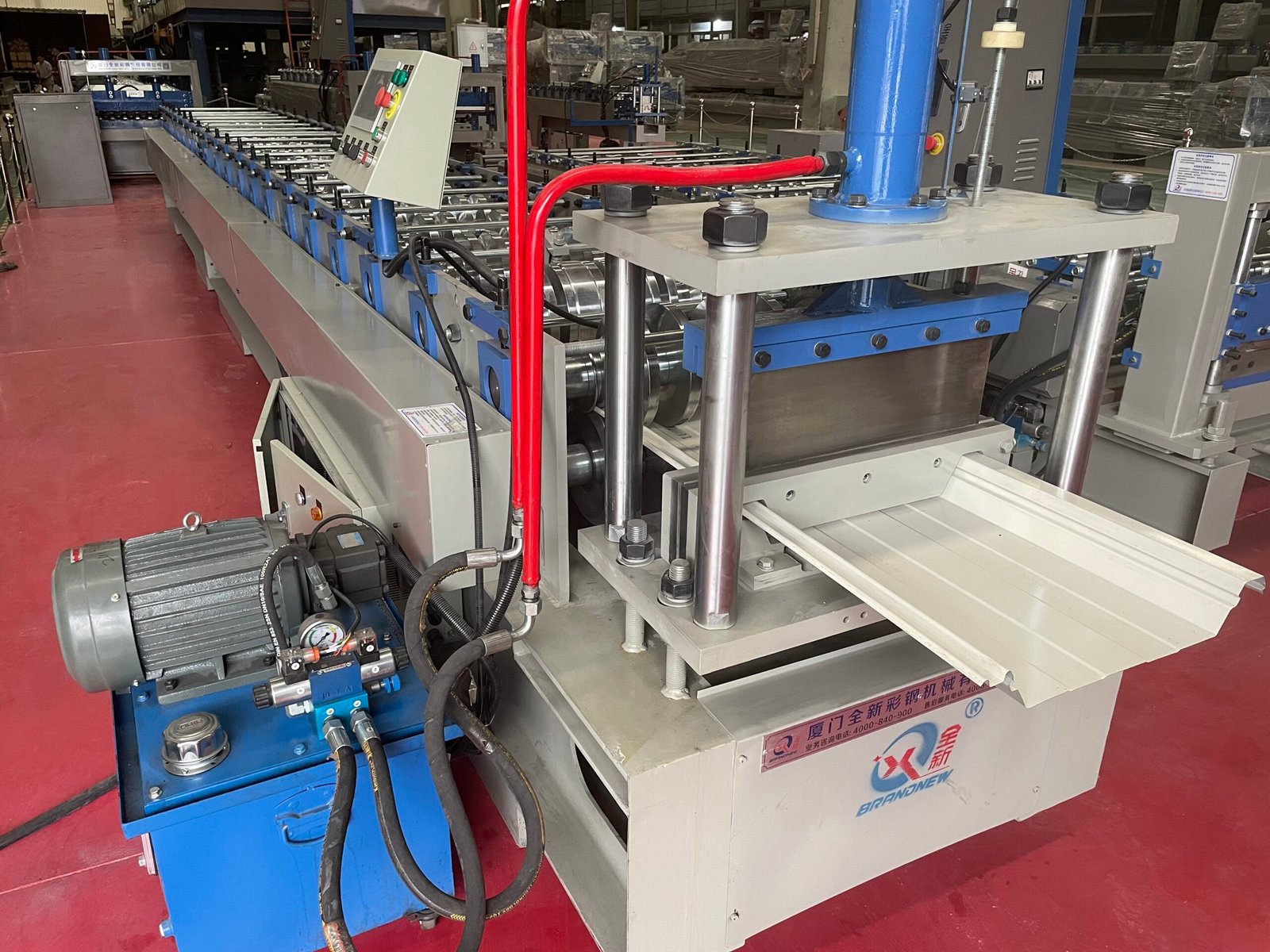

The Beenew Machinery-developed Solar C&U Channel Roll-Forming Line is a dedicated manufacturing system for high-precision structural profiles for the global photovoltaic industry. Integrating cutting-edge roll-forming technology with full-process intelligent automation, it aims to provide a core component production solution for large-scale solar infrastructure projects that combines optimized mechanical properties, consistent quality, and efficient production. Through its modular design and digital control, the line can meet the customized needs of key structural components such as C- and U-shaped steel in photovoltaic racking systems. Its technical features and application advantages represent significant innovations in the field of new energy equipment manufacturing.

1. Technical Architecture: Deep Integration of Roll-Forming and Intelligent Control

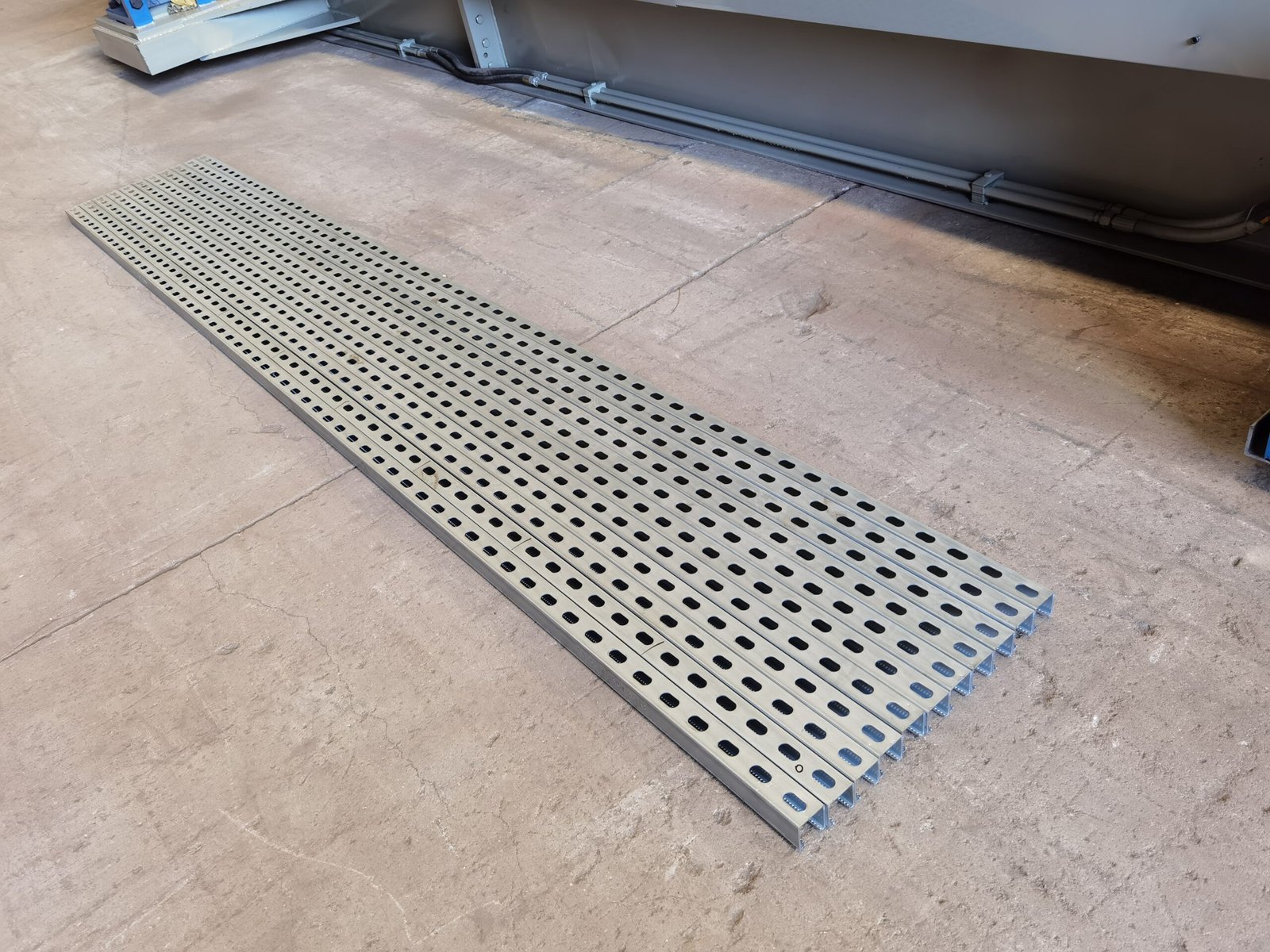

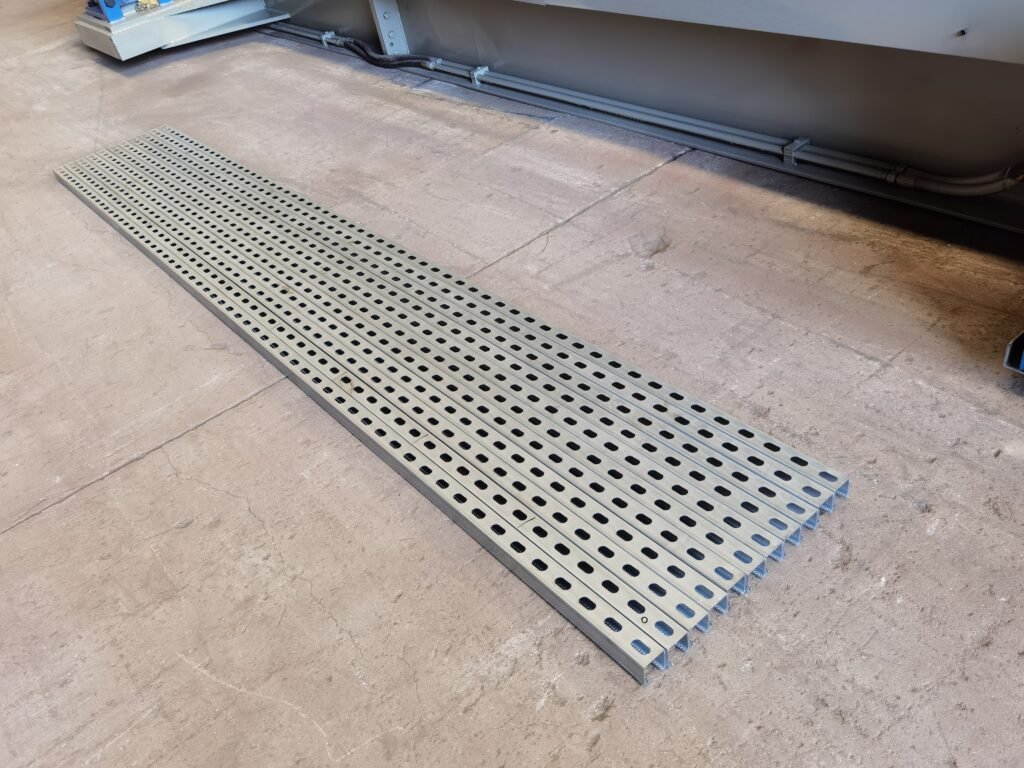

The core advantage of this line lies in the collaborative operation of its multi-station precision roll-forming unit and Industrial Internet of Things (IIoT) control system. The roll-forming module utilizes a progressive forming process, with 20-25 sets of high-precision rollers (made of Cr12MoV die steel with a surface hardness of HRC58-62) continuously cold-bending the coiled material (hot-dip galvanized steel or aluminum alloy sheet with a thickness range of 1.5-4.0mm). This ensures that the cross-sectional dimensional tolerance of the profile is controlled within ±0.3mm, and the straightness error is ≤1mm/m, fully meeting the stringent structural stability requirements of photovoltaic racking systems.

The intelligent control system, equipped with a Siemens S7-1500 PLC and a visual inspection system, collects key parameters such as stress distribution, roller speed matching, and material springback during the forming process in real time. It dynamically adjusts the roller gap and feed speed using an adaptive algorithm. Furthermore, the production line integrates an online laser thickness gauge and eddy current flaw detector for full-scale inspection and surface defect detection of the formed profiles. This achieves a defective product detection rate of 99.8%, effectively preventing safety hazards in downstream installation.

2. Performance Advantages: Comprehensive Optimization from Material Utilization to Structural Strength

In terms of production efficiency, this production line utilizes a dual-station coil unwinding mechanism and a flying shear cut-to-length system, enabling non-stop coil changes and high-speed cutting (maximum line speed of 30m/min). This allows for single-shift production capacity of 15-20 tons, an increase of over 40% compared to traditional stamping processes. In terms of material utilization, the waste-free layout design and scrap recovery device keep raw material loss below 3%, significantly reducing the overall cost of photovoltaic projects.

In terms of structural performance, the roll-forming process increases the profile’s cross-sectional moment of inertia by 20%-30% compared to welding processes, enhancing its bending bearing capacity by 15%. It can withstand extreme climate conditions ranging from -40°C to +80°C and withstand force 12 typhoon loads. To meet different project requirements, the line supports variable cross-section forming (such as variable height and flange width), enabling customizable extra-long profiles from 6-12 meters in length. This reduces on-site splicing nodes and improves the overall wind vibration resistance of the photovoltaic array.

3. Application Scenario: Customized Production for Large-Scale Photovoltaic Projects

This production line primarily serves ground-based centralized photovoltaic power plants, distributed industrial and commercial photovoltaic power plants, and building-integrated photovoltaic (BIPV) projects. It manufactures core components for photovoltaic support systems, including main beams, purlins, and diagonal braces. For example, in desert photovoltaic power plants, the C-shaped steel supports produced undergo hot-dip galvanizing and passivation treatment, withstand salt spray tests for over 1,000 hours, and meet corrosion resistance standards for a 25-year service life. In rooftop photovoltaic projects, lightweight U-shaped steel purlins can reduce building loads by 15%-20%, adapting to the diverse installation requirements of steel structures and concrete roofs. In addition, the production line has the ability to quickly change molds (changeover time ≤ 30 minutes), is compatible with a variety of materials such as Q235B, Q355B, 6061-T6, supports customer-customized cross-sectional dimensions (such as C-shaped steel inner curling, U-shaped steel strip reinforcement and other special designs), and flexibly responds to photovoltaic bracket standards in different regions of the world (such as China’s GB 50797, the United States AISI S100, and Europe’s EN 1090).

Related Products

Request A Quote

If you have any questions or require more detailed information about our roll forming solutions, please contact us by clicking on the link below.

Our product specialists will be in touch with you shortly to discuss your requirements!