Material Type | Seel strip |

Thickness(mm) | 0.8-1.5 |

Yield stress(Mpa) | 235-350 |

Max. Forming speed(m/min) | 25m/min |

Roller material | 45# steel with hard chrome treatment |

Roller driven type | Chain transmission |

Controller | PLC |

Operation | Touch screen and button |

Hydraulic system pressure(Mpa) | 12 |

Hydraulic station motor power(KW) | 7.5 |

Main motor power(KW) | 15 |

Total weight(Kg) | About 95000 |

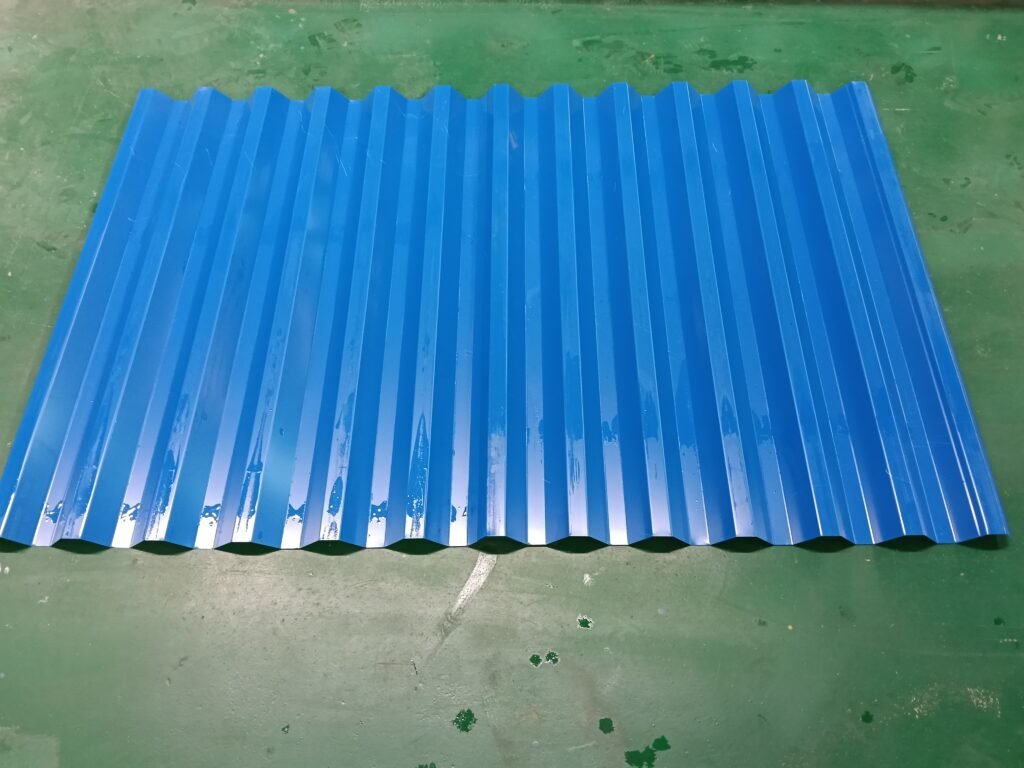

Roofing sheet making machine are used to produce metal roofing,the production line including steel coil un-coiler,metal sheet feeding & leveling system,roll forming mill,hydraulic system,cutting system,PLC control system,product rack.

Roofing has PV and metal two materials,nowdays,more and more customers choose metal sheet roofing.We are the factory who manufacturing metal roofing roll forming machine,this profile made by our machine not only can use for the roofing,but also can use for the wall.

The main metal roof roll forming machine designed accroding your profile drawing. The machine’s main parts are the rollers,use Cr12 Mov material with CNC lathes,more wear-resisting,more durable.

The cutting blade use Cr12 materal,that can cut the profile smoothly and no burr.

On the picture of the metal profile samples, there are two pieces of the metal profile lapped together,looks beautiful and you can’t see the seam crrossing.

If you have any questions or require more detailed information about our roll forming solutions, please contact us by clicking on the link below.

Our product specialists will be in touch with you shortly to discuss your requirements!