Metal Roofing Machine

Metal Roofing Machine

Roof Sheet Making Machine

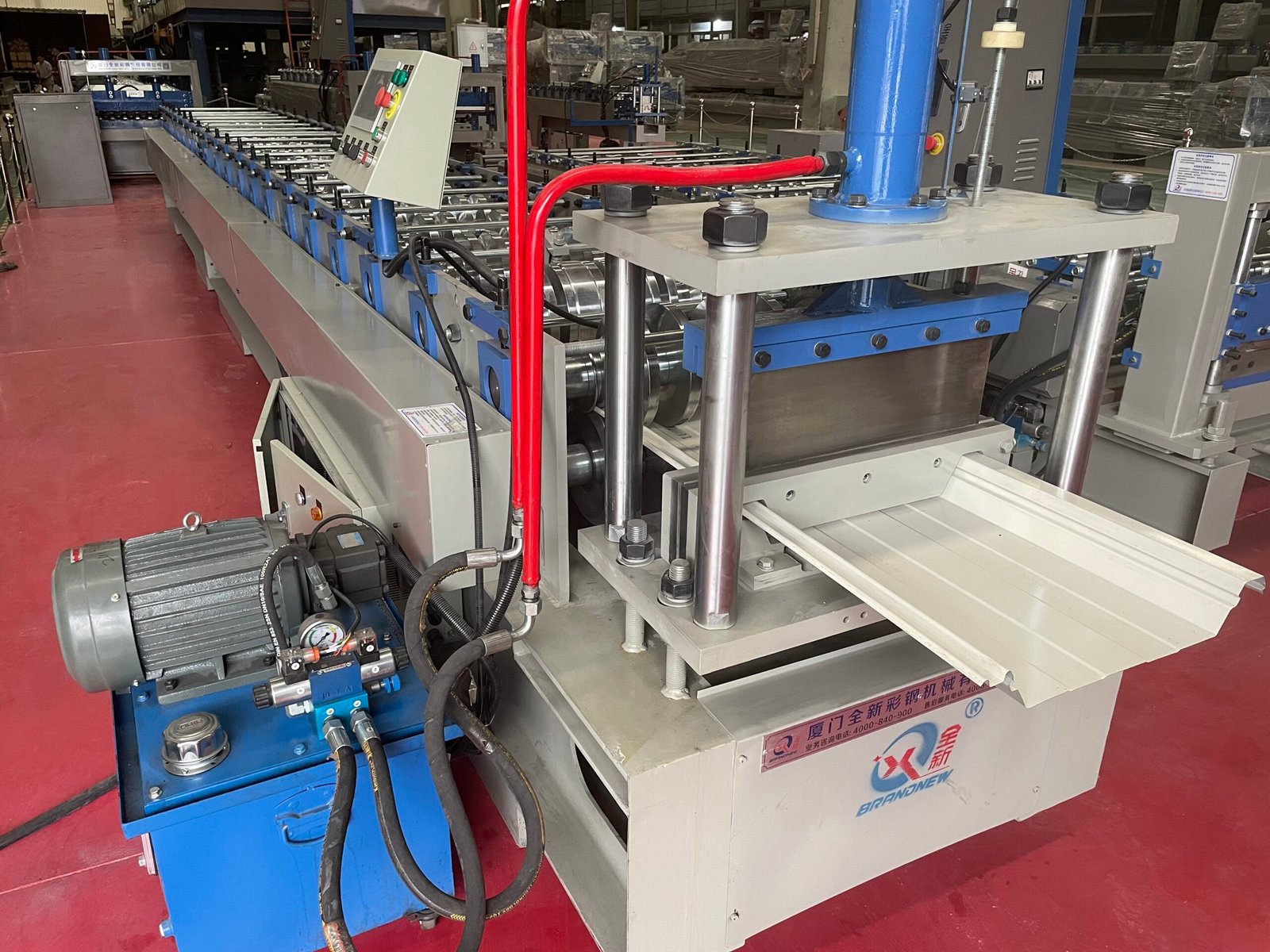

We have roofing sheet manufacturing machine. Metal roofing sheet is a relatively economical roofing material in the construction industry and is resistant to high temperatures. For this reason, Beenew provides you with roofing sheet making machine. In addition, metal roofing panels produced from color steel coil raw materials are lighter than concrete or clay tile roofing panels, more durable than asphalt shingles, and easier to maintain and replace than non-replaceable disposable roofing tiles. In addition, it is a reliable and economical roofing system in the construction industry with a variety of designs and styles, and customers have a lot of choices. In addition, metal roof tiles can be made into the style of other roofing materials, such as glazed tiles.

At the same time, our roofing sheet machine can be fully customized, and architects and building designers can make diversified designs for differentiated exterior walls and metal roofing applications, and our roof tile making machine can have suitable forming solutions. Finally, please contact us for more information about roofing sheet making machine. In fact, Beenew Machinery provides you with a variety of high-quality roll forming machines to meet your metal roofing manufacturing needs.

Types of metal roofing

Therefore, Beenew Machinery introduces you to a variety of metal roofing and wall panels. Please browse the following content to learn about our roof tile and wall panels.

- Corrugated metal roof panels

- IBR roofing

- R panel

- RIB panel

- AG panel

- Standing seam roof

- Glazed tile

- Metl span wall panels

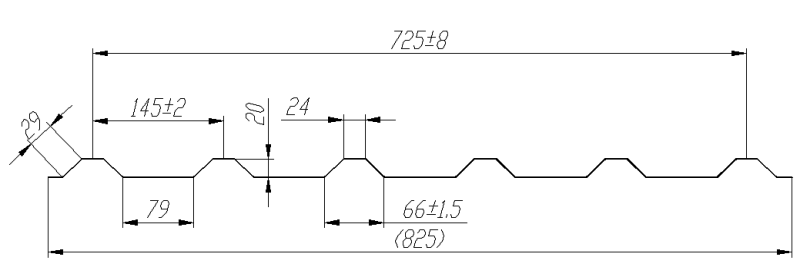

Machine to make metal roof

In conclusion, Beenew Machinery designs and produces a wide range of metal roofing machines. Similarly, these panels are not only used for roofing, but are also very suitable for covering the sides such as walls. Application scenarios also include large industrial, stadiums and agricultural buildings. They can also increase privacy and increase security. Therefore, the cladding panels corrugated steel used for walls are quite strong profiles. The appearance can be customized and designed. They are also suitable for protected areas, fence panels, etc. Cladding panels corrugated steel is an ideal choice for side cladding walls of warehouses, farms, barns, factories, etc. Therefore, the following are the common types of metal roofs produced by our steel roofing machine:

- Standing seam metal roof

- IBR roofing

- Steel roofing

- Corrugated roofing

- Aluminum roofing

- Wall cladding panel

- Snap lock panel

- Trapezoidal roofing

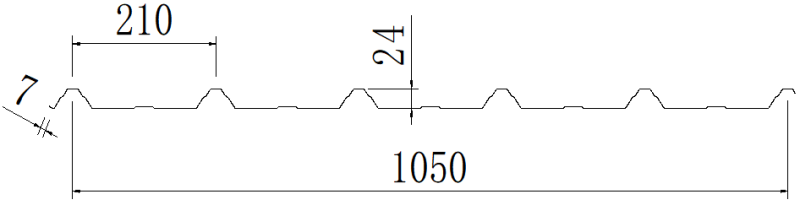

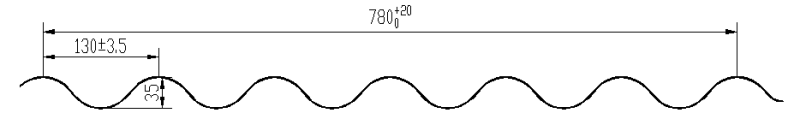

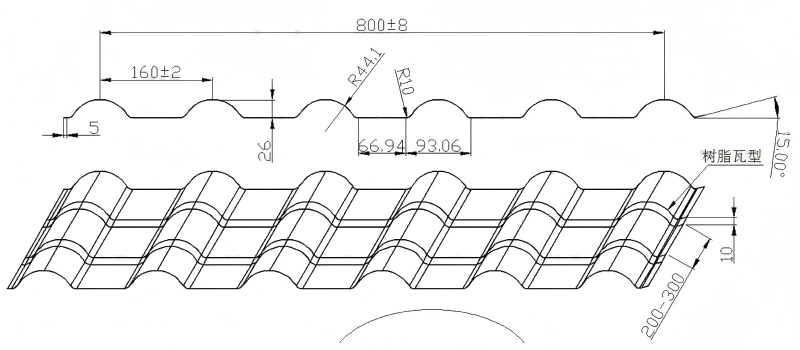

Corrugated sheet roll forming machine

Likewise. Color coated corrugated sheets are widely used by the construction industry around the world because of their good corrosion resistance, good appearance and durability. Therefore, corrugated sheets are widely used in steel structure buildings, enclosure systems, especially popular in Australia. The installation method of corrugated profiles is simple, providing you with an economical roof covering and wall panel. In fact, Beenew Machinery can produce a variety of high-quality corrugated sheet roll forming machines according to your requirements, according to different sheet thickness and load capacity.

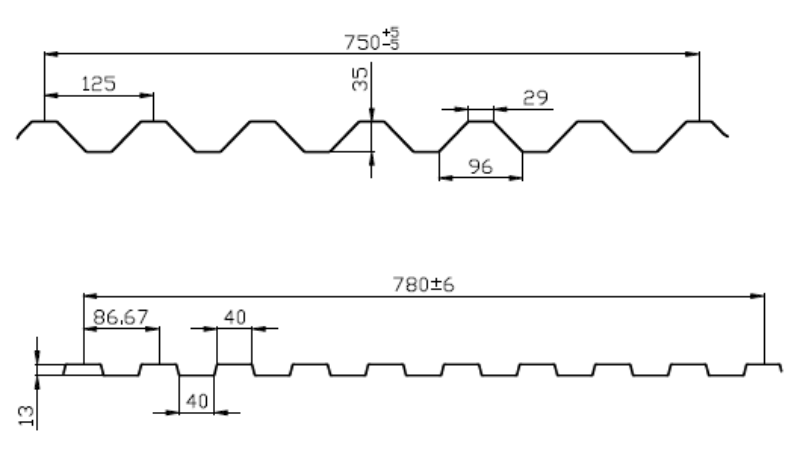

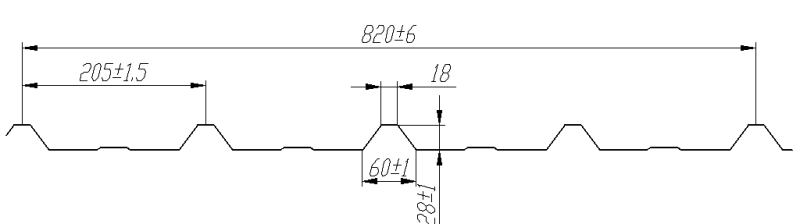

IBR making machine

Meanwhile, lBR roofing sheets are widely used in steel structure buildings and construction industries, such as side cladding or roofing of commercial, industrial and residential buildings. lBR is the abbreviation of “inverted box rib”, which is well known in the construction industry of African countries, such as South Africa. Of course, IBR roofing sheets can be selected in different materials and colors according to customer needs, and the structural characteristics are diversified.

lBR roofing evolved from zinc roof tiles, which is a fast and easy to install sheet. However, its raw materials are more selective, such as steel, aluminum and stainless steel. There are many types of lBR sheet profiles, however, in African countries, such as South Africa, the more common lBR sheet profiles are lBR 686 profiles and lBR 890 profiles, which are widely used as building roof cladding sheets or side cladding. Compared with other metal roof sheet roll forming machines, 686 lBR sheet profile forming machine is more popular.

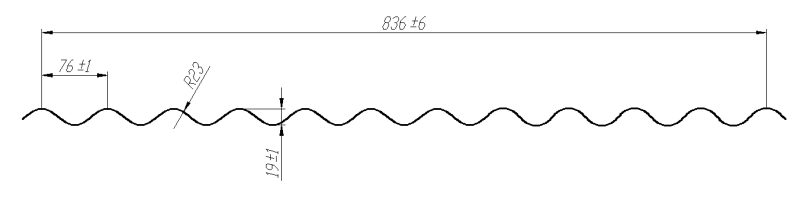

Steel roofing machine

In addition, steel roofing is widely used in wall panels and roof tiles. In addition to ordinary galvanized steel, there are also stainless steel panels. Therefore, different steel coil raw materials can be selected according to your different needs. The forming rollers of the steel roof panel making machine are made of chrome-plated rollers. The steel sheet passes through the upper and lower rollers to produce different roof tiles and wall panels. Beenew Machinery’s roll forming machine can produce sheet profiles of different steel coil raw materials.

Roofing machine

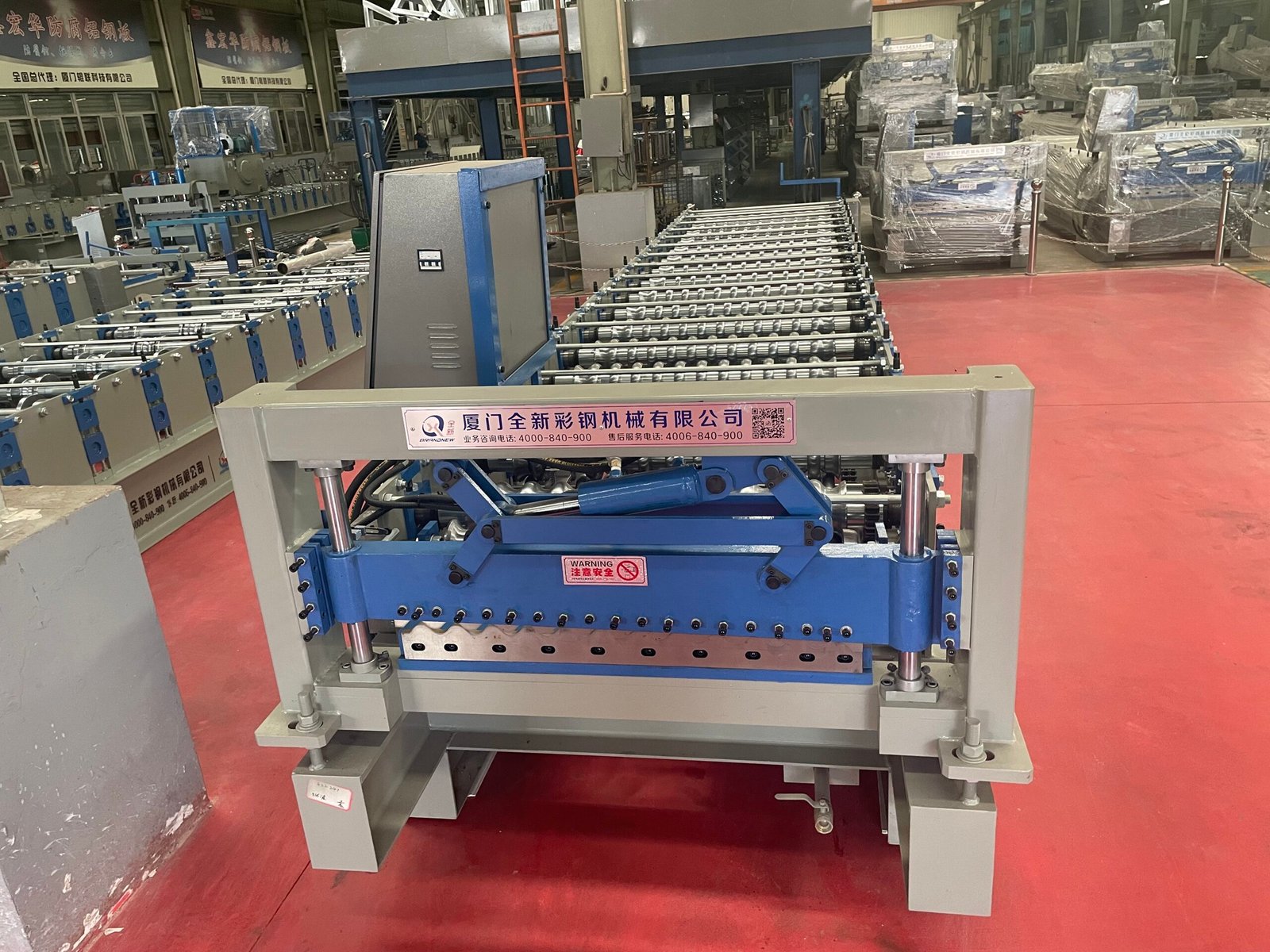

Beenew Machinery has always been one of the leading roofing machine manufacturers in China’s roof and wall covering industry, specializing in designing and manufacturing various roofing machines such as roll forming machine, corrugated sheet machine, IBR roofing machine, etc.

Material

Galvanized sheet,Tension Grade: Q235MPa-Q350MPa

Thickness: 0.5-0.8mm

Effective Width:960mm

Coil Feeding Width Max. 1250mm

Decoiler

Un-powered, 7T

Coil inner–diameter: 508±30mm

Coil outer-diameter: Max. 1200

Load capacity= Max. 5Ton

Coil Width= Max. 1250mm

Roll forming machine

Feeding table with guide,

Gear/Sprocket driving; Dual Leveling

Driving Motor:5.5KW

Forming Station:16 GROUPS

Roller Material:45# steel,Gcr15, chrome coated with heat treatment, HRC58-62°

Shaft Diameter:70mm

Shaft Material:45# steel,heated and quenched

Forming speed: Approx.18-20m/min

Machine frame:450 H-beam, Stress-Relieving

Hydraulic stamping&cutting Device

Cutting type:Hydraulic stop cutting

Hydraulic pump power:4KW

Hydraulic pressure:12 Mpa

Hydraulic blade&cutter material:Cr12, quenching process 58-62

Cutting length tolerance:10m±2mm

Electrical system

PLC Control System

Voltage:380V/50Hz/3P

How to choose roof sheet making machine?

In short, metal roofing is produced by roofing sheet making machine, which is widely used in metal roofing tiles, IBR panels and common color-coated roofing tiles in buildings, factories and houses. Therefore, you can contact Beenew machinery, which has more than 28 years of experience in metal roofing machines and can produce up to 500 different panel profiles. Therefore, according to the customer’s use, Beenew machinery produces metal roof forming machines, which are divided into two types of machines: normal speed and high speed. In addition, when choosing a metal roof sheet making machine manufacturer, you should weigh the workshop capacity and the production experience of the roll forming machine to choose a sheet roll forming machine.

In addition, Beenew machinery can design and manufacture various types of roofing tile forming machines. PPGI and GI sheets can be produced at different speeds according to your needs. In addition, we specialize in manufacturing roofing tile manufacturing machines with gearbox transmission, which can produce high-quality profiles with precise lengths. Our high-speed roofing machine is used in conjunction with servo motors to reduce tolerances and increase speeds. We design all roofing sheet manufacturing machines according to your drawings.

We have professional engineers to design stamping dies, and achieve customer-satisfactory shapes through processing processes such as wire cutting, hardening, surface processing and final heat treatment. Finally, the Beenew machinery glazed roofing tile forming machine uses a frame produced by high-strength steel, which enables the forming machine to run stably.

To sum up, there are common problems about roofing panel manufacturing machines. Our engineers and technicians usually collect and organize them, so you can contact our technical team at any time.

Roofing Sheet Materials

1. Iron, an early, relatively inexpensive material for making roof tiles, corrugated zinc iron is the main type of iron metal roof. To increase durability, the iron sheet is often coated with steel.

2. Galvanized steel, the most commonly used metal roofing material today, is steel coated with zinc. Similarly, there is galvanized steel coated with aluminum, which is available in a variety of colors. The metal roof panels produced by this material have good corrosion resistance, long life and high strength.

3. Stainless steel, a relatively expensive metal roofing material. Compared with other roofing materials, stainless steel is a bit more expensive. However, it is very strong and durable, and it is an ideal choice for customers who need a higher-end roof panel and wall panel.

Rating us

Product Name: METAL ROOFING MACHINE

Product Description:

Beenew Machinery have more kinds of roof sheet making machine and profile sheet making machine.

Brand: Beenew

Currency: $

Availability: InStock

Request A Quote

If you have any questions or require more detailed information about our roll forming solutions, please contact us by clicking on the link below.

Our product specialists will be in touch with you shortly to discuss your requirements!