Shipping Container Roll Forming Machine

Shipping Container Roll Forming Machine

Shipping Container Making Machine

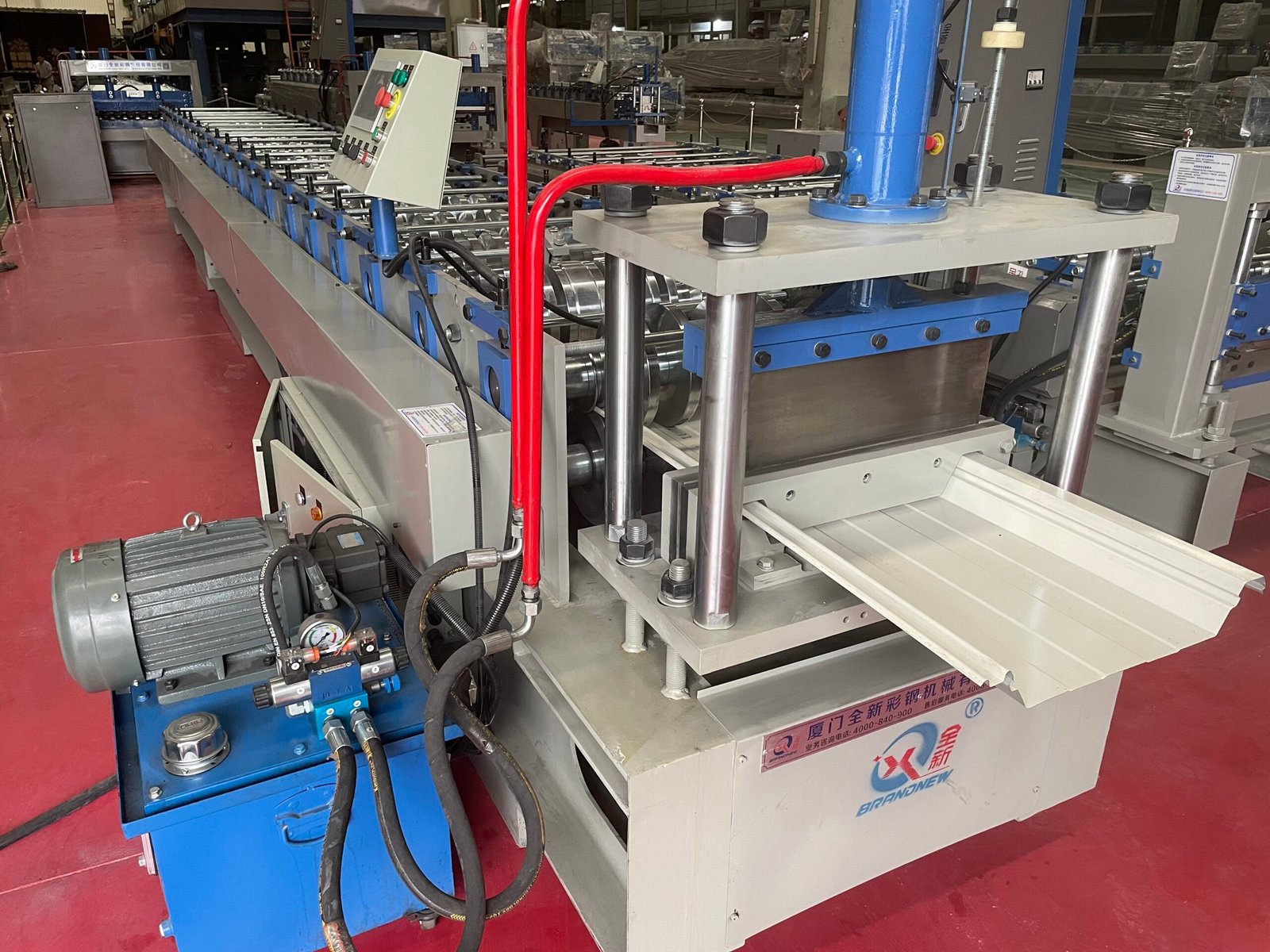

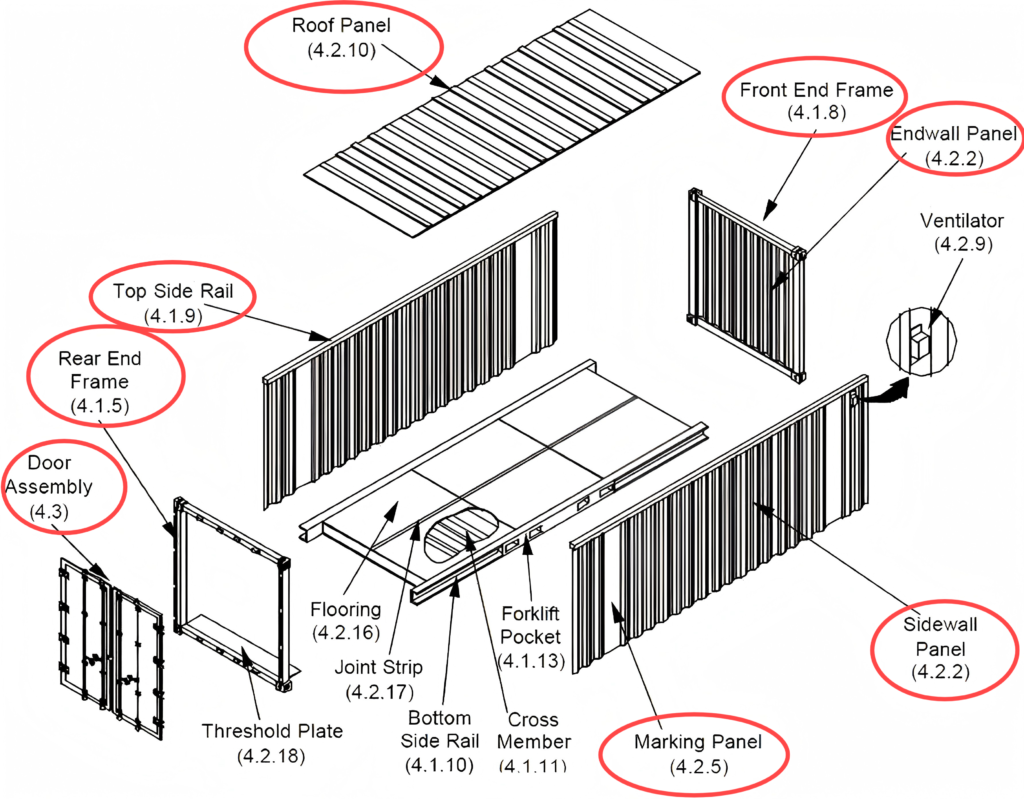

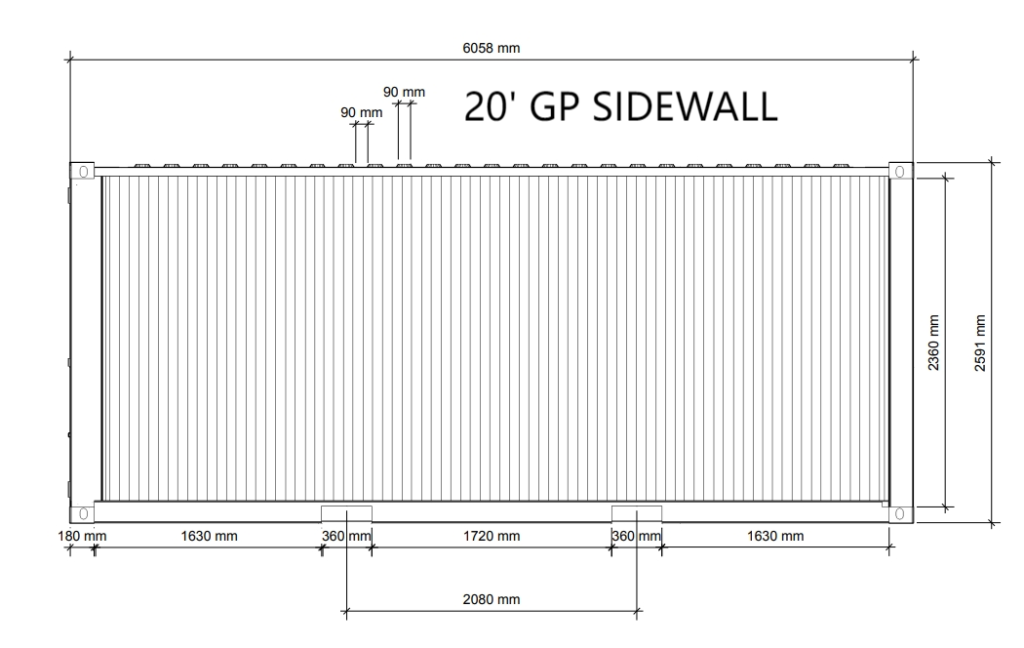

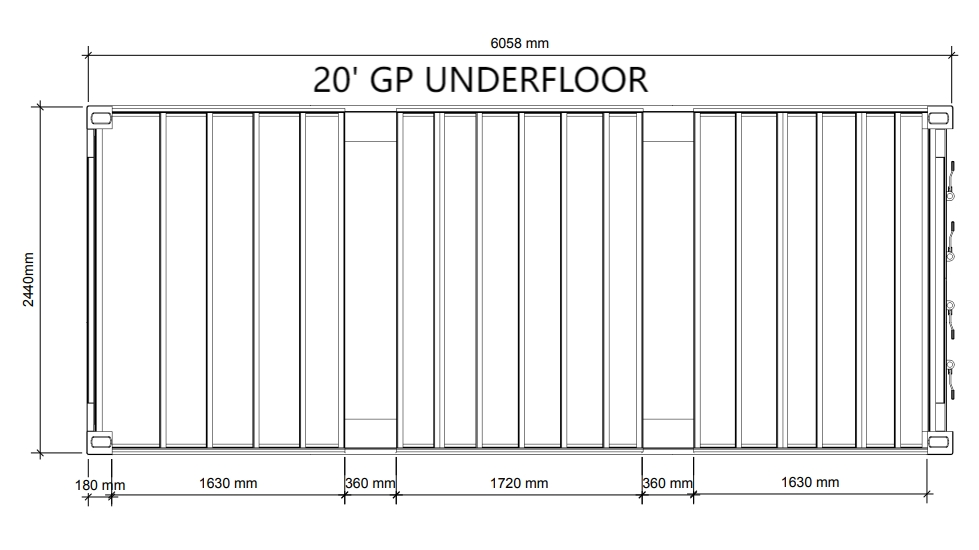

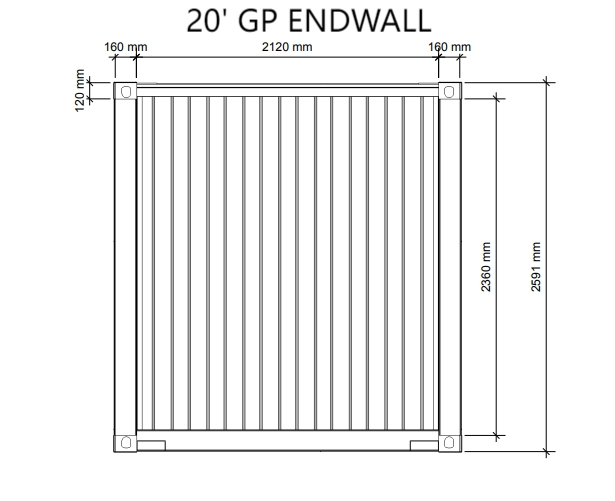

The shipping container making machine is specifically engineered for the manufacturing of shipping container panels. The production process commences with large steel sheets. These sheets are precisely cut down into smaller, more manageable sizes. Once the sheets are cut, a metal roll – forming process is initiated. This process uses specialized machinery to gradually shape the smaller sheets into the specific form required for the container panels.

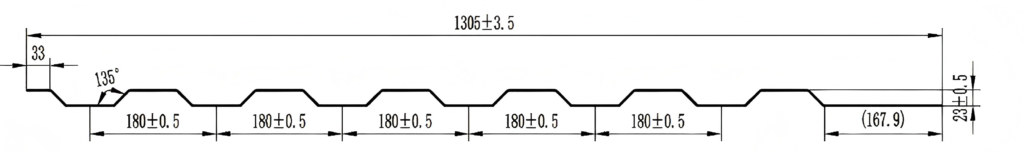

Following the roll – forming process, the sheets are subjected to a corrugation process. Corrugation involves creating a series of parallel ridges and grooves on the surface of the sheets, giving them a wave – like texture. This corrugated design is not just for aesthetic purposes; it significantly enhances the structural strength of the container walls. By distributing stress more evenly across the surface, the corrugation helps the walls withstand the various forces they may encounter during transportation and storage.

After the corrugation, the smaller panels are carefully laid out in a specific pattern. They are then joined together through a welding process. Welding ensures a strong and permanent bond between the panels, creating a single, full – sized wall panel.

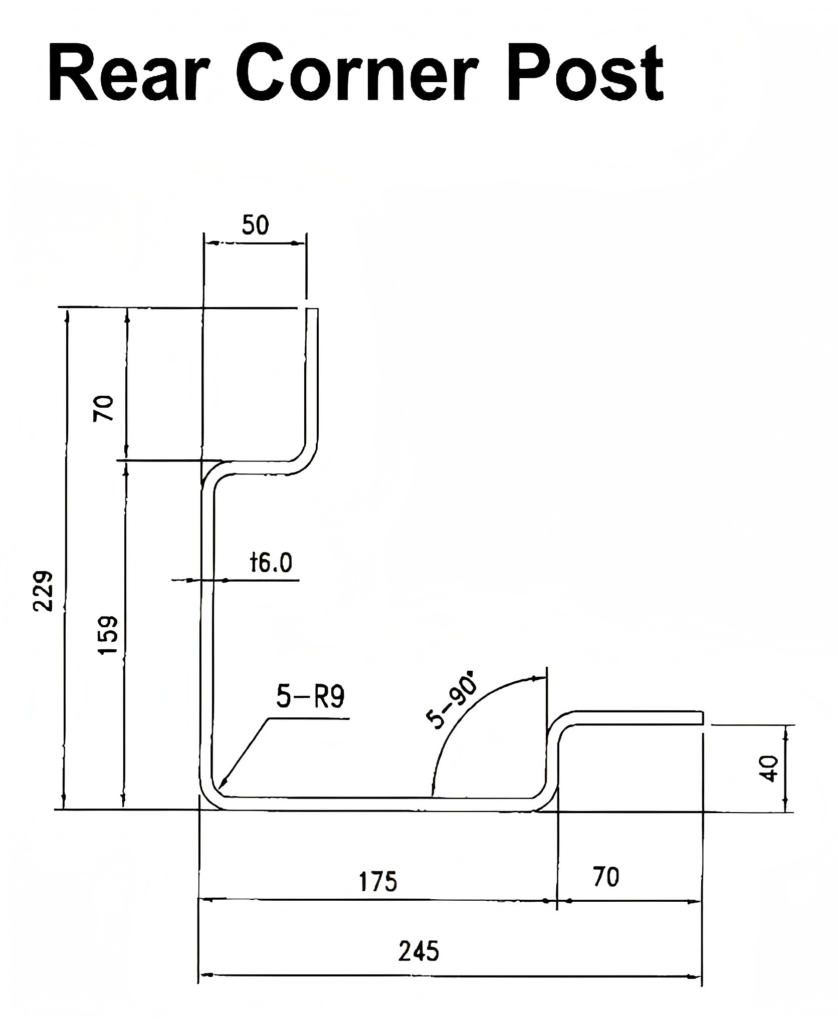

The final step in the production of the wall panels is the attachment of square tubing. Square tubing is welded onto the top and bottom edges of the wall panel. This tubing acts as a connection interface. It allows the wall panels to be securely welded to the floors and roof of the shipping container, ensuring the overall structural integrity of the container.

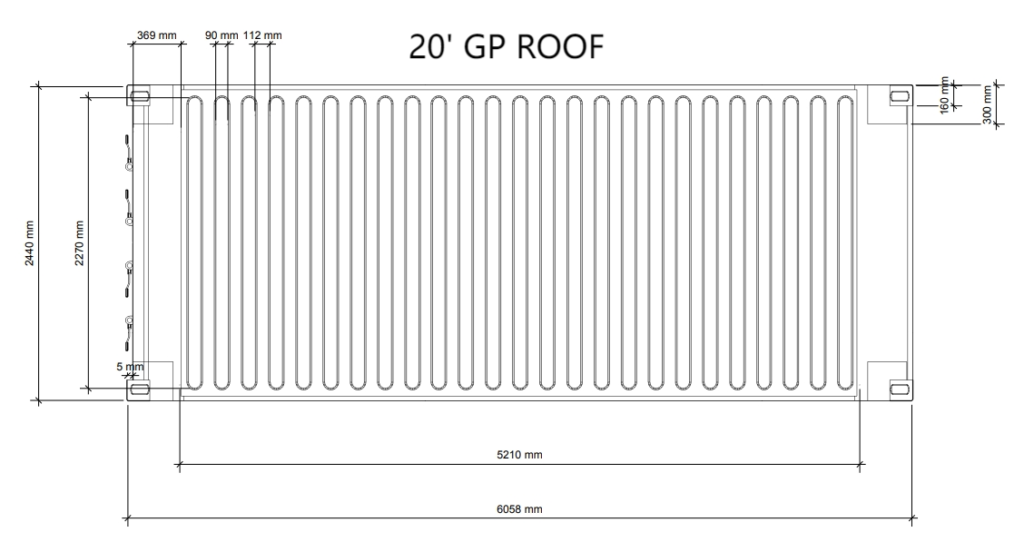

Shipping container roof panel roll forming machine

Material: Corten – A steel (SPA – H)

Material Thickness: 2 millimeters

Size: 1024×2400 (2700) millimeters

Main roll forming machine Power: Two units with 15 kilowatts each

Forming speed: 20 to 25 meters per minute

Main Parts of Shipping Container Making Machine:

Hydraulic uncoiler (equivalent to the mentioned decoiler)

Feeding guiding device

Roll forming mechanism

Hydraulic stop – type cutting device

Control system

Working Process:

Hydraulic uncoiling, Roll forming operation, Hydraulic cutting process, Output onto the table

Container side panel roll forming machine

Roller groups: 30 stations

Material: 45# steel, heat – treated, with a hardness of HRC58 – 62°

Roller shaft diameter: Φ115mm

Shaft material: 45# steel, quenched and tempered

Motor: Two sets of 11.0KW motors

Transmission way: Chain transmission

Machine frame body: 500 H – beam

Roller stand: Wall panel

Hydraulic cutting unit

Cutting way: Hydraulic stop cutting

Cutting die: CR12, quenched

Shipping container roll forming machine

Beenew Machinery is a leading producer of machines dedicated to crafting various structural steel container parts. Whether it’s shipping container man – door kits, side panels, roof repair panels, door hinges, twist locks, or any other structural steel elements, we guarantee high – quality output and the most advanced production lines in the industry.

Related Products

Request A Quote

If you have any questions or require more detailed information about our roll forming solutions, please contact us by clicking on the link below.

Our product specialists will be in touch with you shortly to discuss your requirements!