Roof Sheet Making Machine South Africa Price

Roof Sheet Making Machine South Africa Price

Roof sheet making machine south africa price

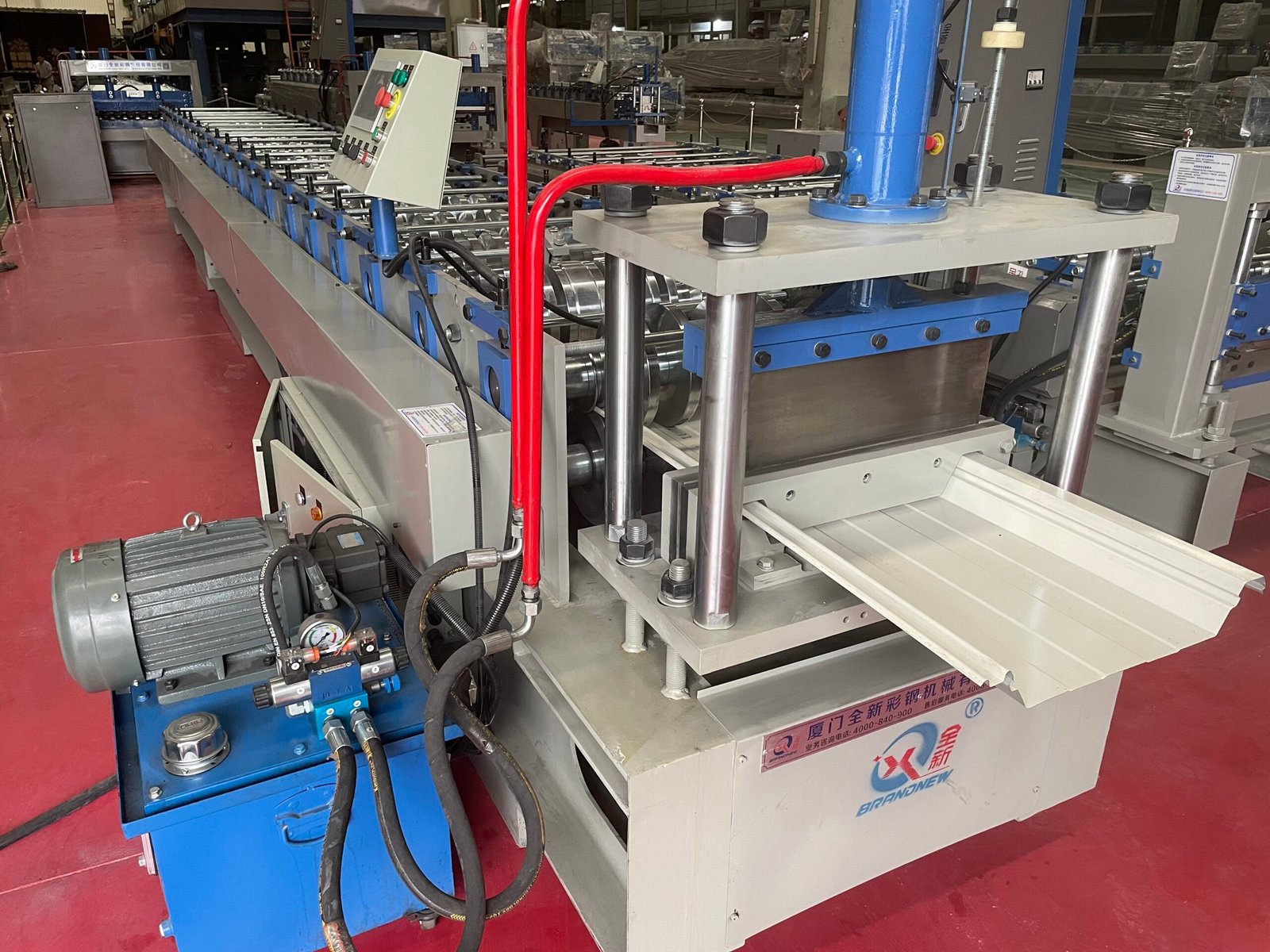

Beenew roof sheet making machine produces roof tiles for roof panels that feature an aesthetically pleasing appearance and vivid colors.

These roof tiles enjoy extensive applications across various settings. They are commonly used in garden structures, industrial factories, holiday resorts, hotels, exhibition halls, vacation areas, ancient-style buildings, as well as modern villas.

After-Sales Service for roof sheet making machine south africa price

1. Warranty:We provide a warranty of two years for our equipment. Beyond this period, we are committed to offering technical support for the entire lifespan of the product.

2. Delivery Time:Once we have received your deposit payment, the delivery of the equipment will be completed within 25 – 35 working days.

3. Guarantee Period:For the initial 24 months, all maintenance and service for the machine are free of charge. After this two-year complimentary service period, we will still be available to provide paid maintenance services throughout the machine’s lifetime.

4. Installation and Training:Should buyers choose to visit our factory for machine inspection, we offer an added benefit. Our team of experts will not only guide you through the installation process and show you how to operate the machine effectively but also provide in-person training for your workers or technicians.

Roof sheet making machine south africa price Packaging & Shipping

1. Roof sheet making machine and uncoiler are packed it with water-proof plastic

2. The PLC control system and motor pump are wrapped with waterproof paper. Spare parts are placed in carton boxes

3.One set of the machine requires a 40′ container for shipping

FAQ

Q: Are you a trading company or a manufacturer?

A: We are a direct manufacturer with a dedicated production team and export-focused service expertise in cold roll forming machinery.

Q: Can the machine produce only one panel profile?

A: No. Our machines are engineered for multi-profile versatility, supporting wider and dual-layer production capabilities. A single unit can produce 3+ distinct panel profiles with tooling adjustments.

Q: What is the typical lead time for machine production?

A: Standard lead time is 20–45 business days. For urgent orders, we prioritize production to expedite delivery without compromising quality.

Q: How is quality control ensured during manufacturing?

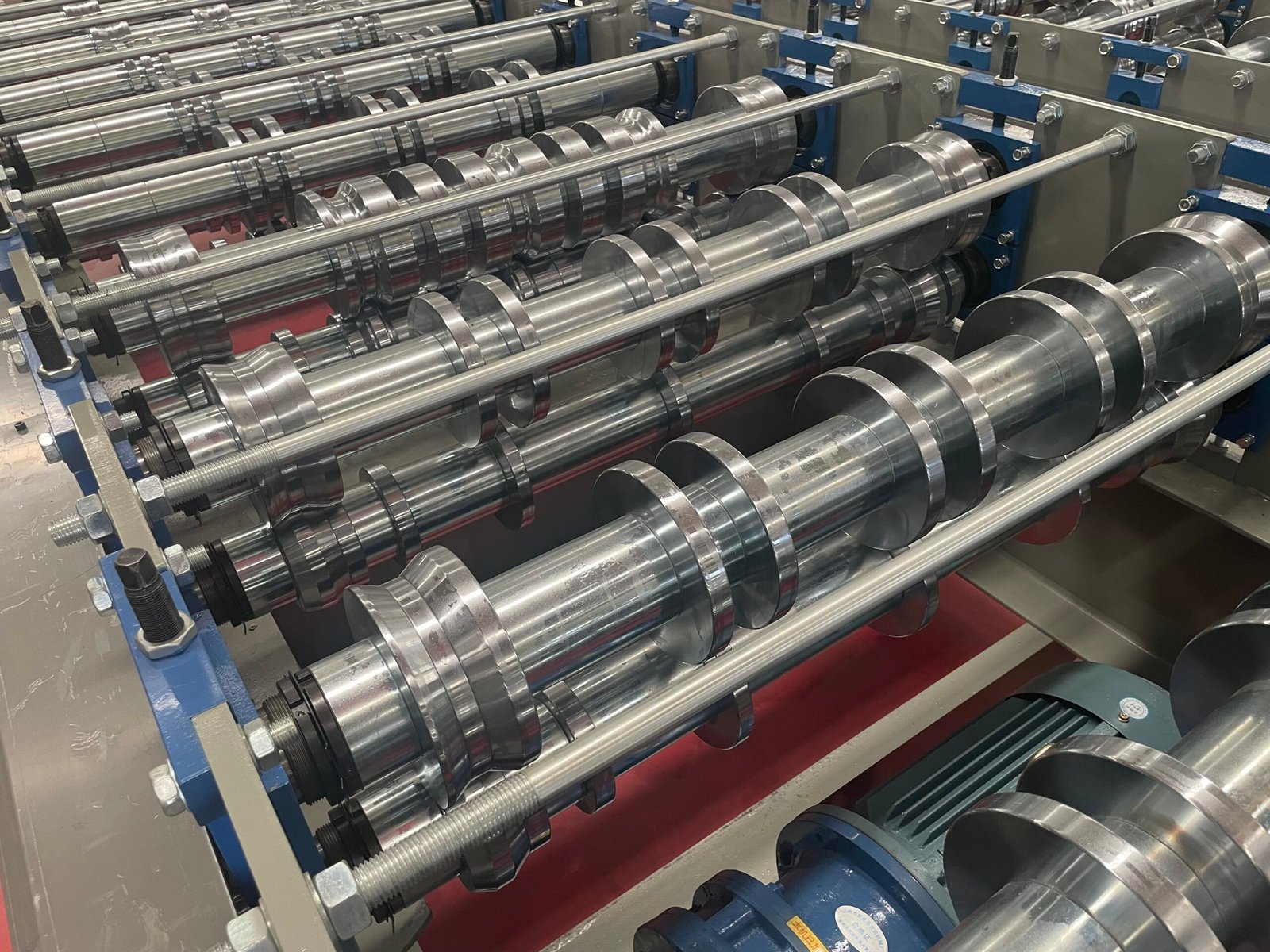

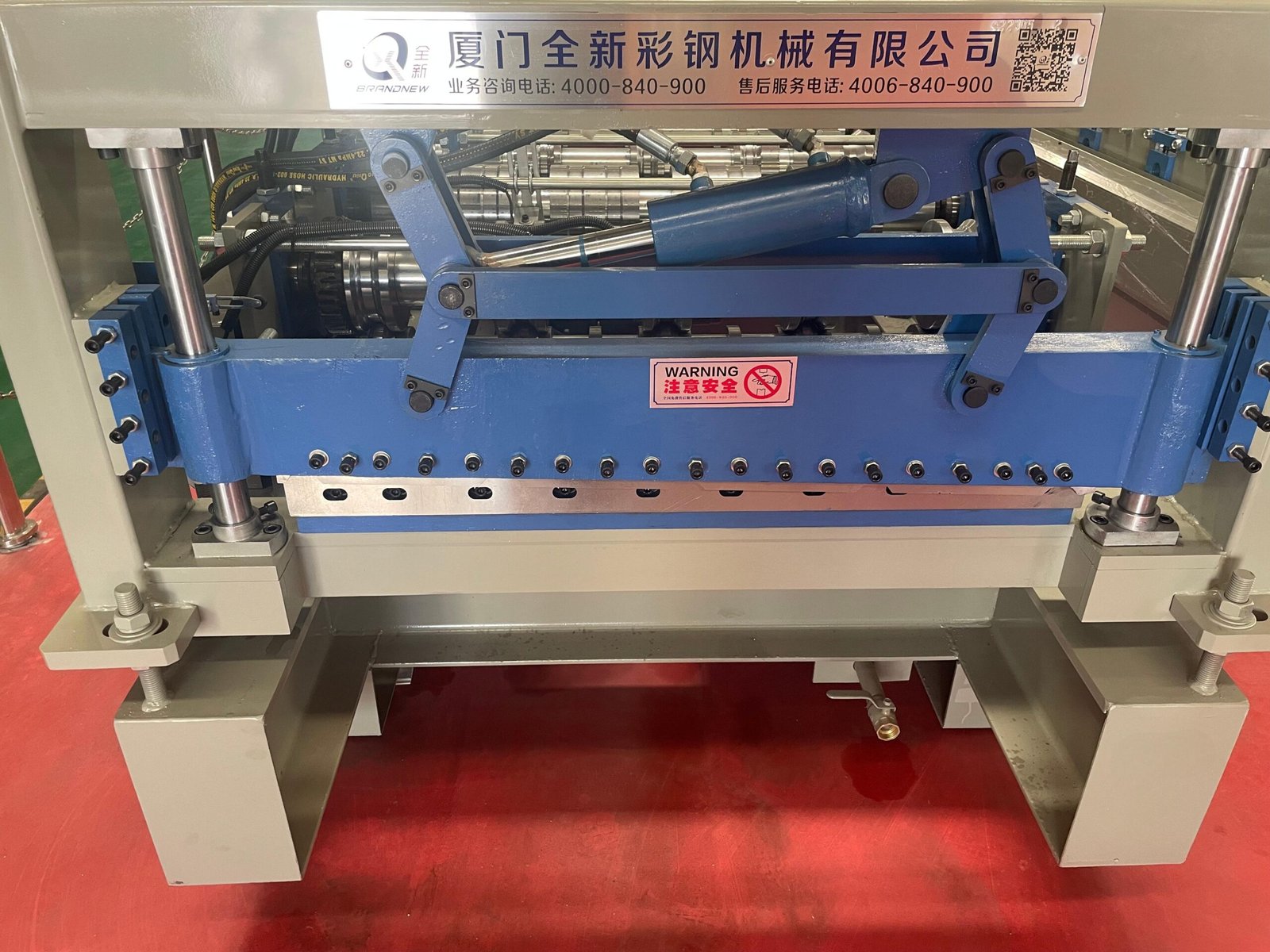

A: Our rigorous QC protocol includes raw material inspection,precision machining of rolls and critical components.

Assembly verification,surface and shaft integrity testing,pre-shipment operational trials and packaging checks.

Q: What if the machine malfunctions?

A:24-month warranty,Free replacement of irreparable parts (customer covers shipping fees).

Post-warranty support: Lifetime technical assistance and negotiated repair solutions.

Q: What differentiates you from competitors?

A: Our strengths include customer-centric service with tailored engineering solutions.

Low-maintenance, user-friendly designs for quick installation and operation.

Value-added guidance to optimize your ROI and product performance.

Q: Can we partner as your international agent?

A: Absolutely! We actively seek collaborations with distributors or agents to sale our roll forming machine.

No. | Roof sheet making machine south africa price | |

1 | Suitable to process | Galvalume Steel Coil |

2 | Roller | 18 |

3 | Motor Power | 7.5Kw |

4 | Pump Station Motor | 4.0Kw |

5 | Thickness of the plate | 0.3-0.8mm |

6 | Productivity | 15-20m/min |

7 | Diameter of the roller | Φ75mm |

8 | Rolling materials | 45# forging steel with chromium plate |

9 | Chain Wheel and Cycle Chain | 1 Inch |

10 | Material of the cutting blade | Cr12,Quenched treatment 58℃-60℃ |

11 | Drive mode | Motor driver |

12 | Processing precision | Within 1.0mm |

13 | Side panel of machine | 18mm |

14 | Main structure of the machine | 350H beams |

15 | Control system | PLC control |

16 | Frequency system | Delta |

17 | Touch screen | Delta |

18 | Length Tolerance | ±2mm |

19 | Voltage | 380V 50Hz 3phases or as customer’s requirement |

20 | Dimensions | 9.5*1.8*1.8m |

21 | Weight | About 7000kgs |

Related Products

Request A Quote

If you have any questions or require more detailed information about our roll forming solutions, please contact us by clicking on the link below.

Our product specialists will be in touch with you shortly to discuss your requirements!