PU Sandwich Panel Machine

PU Sandwich Panel Machine

PU Sandwich Panel Machine

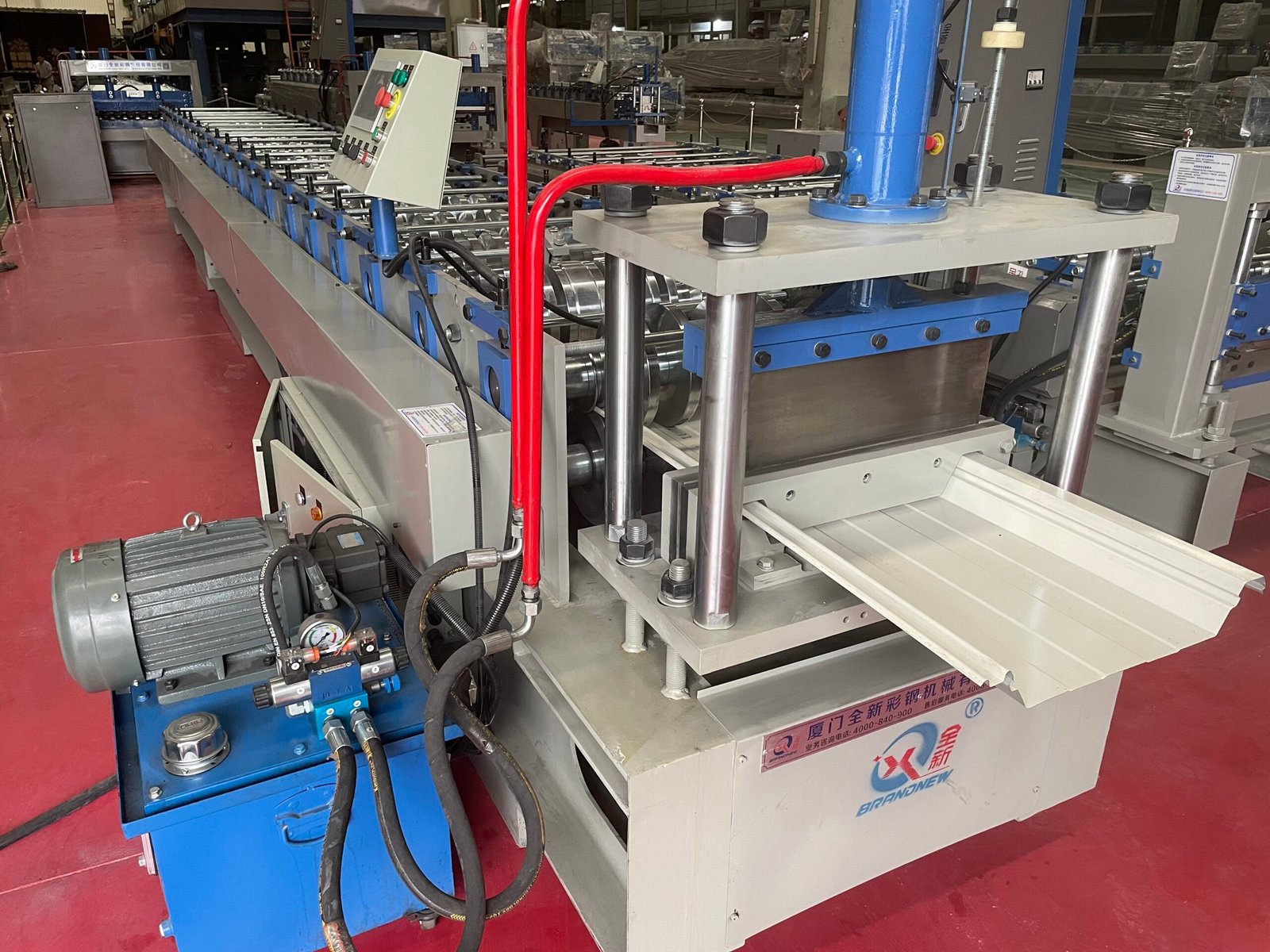

The Beenew PU – 6 continuous PU (polyurethane) sandwich panel production line is specifically engineered to continuously manufacture Z – lock PU sandwich panels.

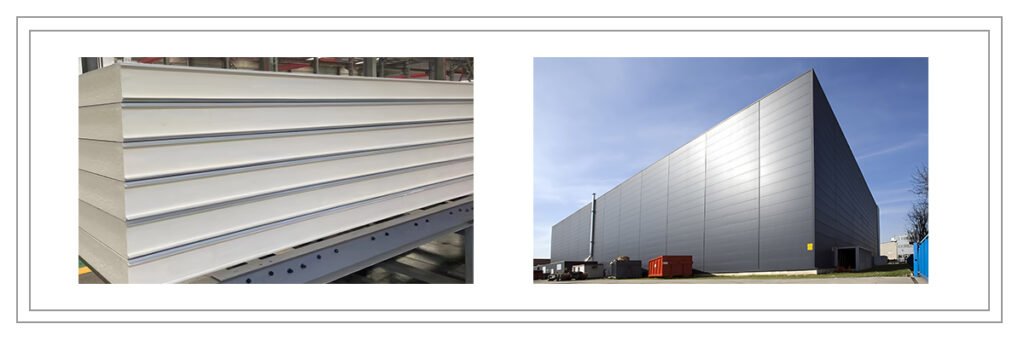

For this panel, facing materials can include PPGl, aluminum foil, PVC sheets, etc. Core materials may consist of polyurethane, mineral wool, glass wool, PIR, phenolic, or EPS.

The panel shape can be customized according to the customer’s specific requirements.

Product pictures

FAQ

Q: Are you a trading company or a manufacturer?

A: We are a direct manufacturer with a dedicated production team and export-focused service expertise in cold roll forming machinery.

Q: Can the machine produce only one panel profile?

A: No. Our machines are engineered for multi-profile versatility, supporting wider and dual-layer production capabilities. A single unit can produce 3+ distinct panel profiles with tooling adjustments.

Q: What is the typical lead time for machine production?

A: Standard lead time is 20–45 business days. For urgent orders, we prioritize production to expedite delivery without compromising quality.

Q: How is quality control ensured during manufacturing?

A: Our rigorous QC protocol includes raw material inspection,precision machining of rolls and critical components.

Assembly verification,surface and shaft integrity testing,pre-shipment operational trials and packaging checks.

Q: What if the machine malfunctions?

A:24-month warranty,Free replacement of irreparable parts (customer covers shipping fees).

Post-warranty support: Lifetime technical assistance and negotiated repair solutions.

Q: What differentiates you from competitors?

A: Our strengths include customer-centric service with tailored engineering solutions.

Low-maintenance, user-friendly designs for quick installation and operation.

Value-added guidance to optimize your ROI and product performance.

Q: Can we partner as your international agent?

A: Absolutely! We actively seek collaborations with distributors or agents to sale our roll forming machine.

Main Parameters

Speed:0 – 8m/min, with frequency control

Total Power:Approximately 200 KVV

Production Line Length Over 100 m

Required Workshop:about 120m x 18m x 5.5m

PU Injection Machine:2 or 4 components, originally from Italy

Related Products

Request A Quote

If you have any questions or require more detailed information about our roll forming solutions, please contact us by clicking on the link below.

Our product specialists will be in touch with you shortly to discuss your requirements!