Metal Roofing Sheet Making Machine

Metal Roofing Sheet Making Machine

Metal Roofing Sheet Making Machine

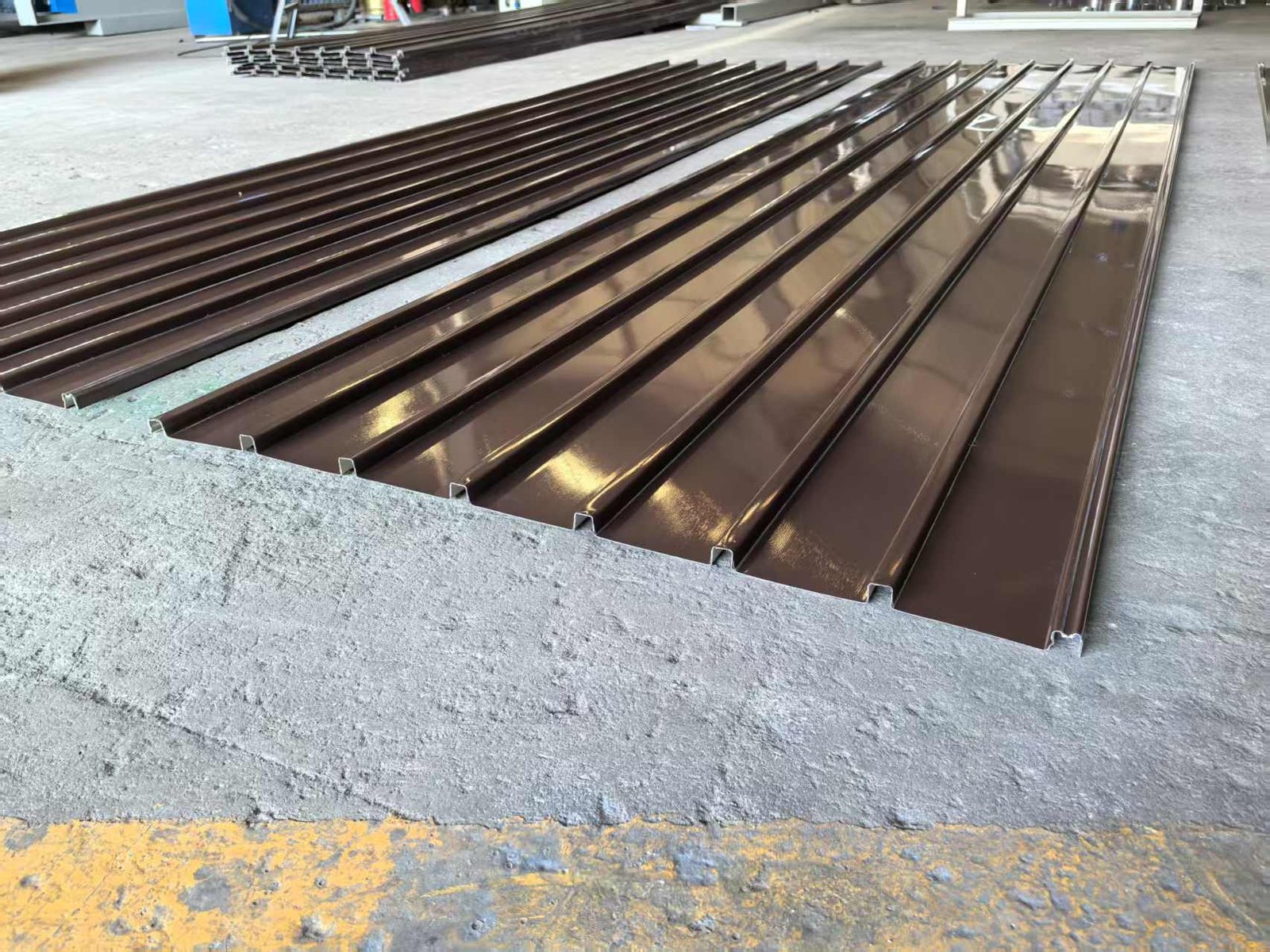

Sheets produced by this metal roofing sheet making machine are of simple but modern outlook. Because of its shape characteristics, it is very good at bearing weight and strength. These metal roofing sheets are not only suitable for roofing, but also for interior wall and roof decoration, store signboard decoration, and station platform roof, etc.

With its unique wave shape and classical flavor, this metal roofing sheet is called “Great Wall Panel ” in China. It has become a bright landscape in modern architecture, realizing the perfect fusion of classical and modern.

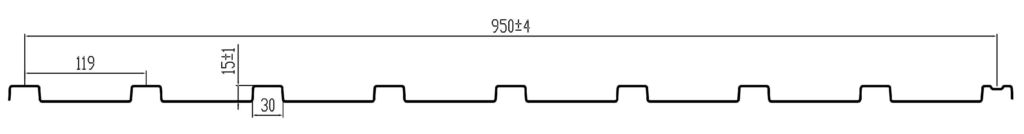

Profile drawing

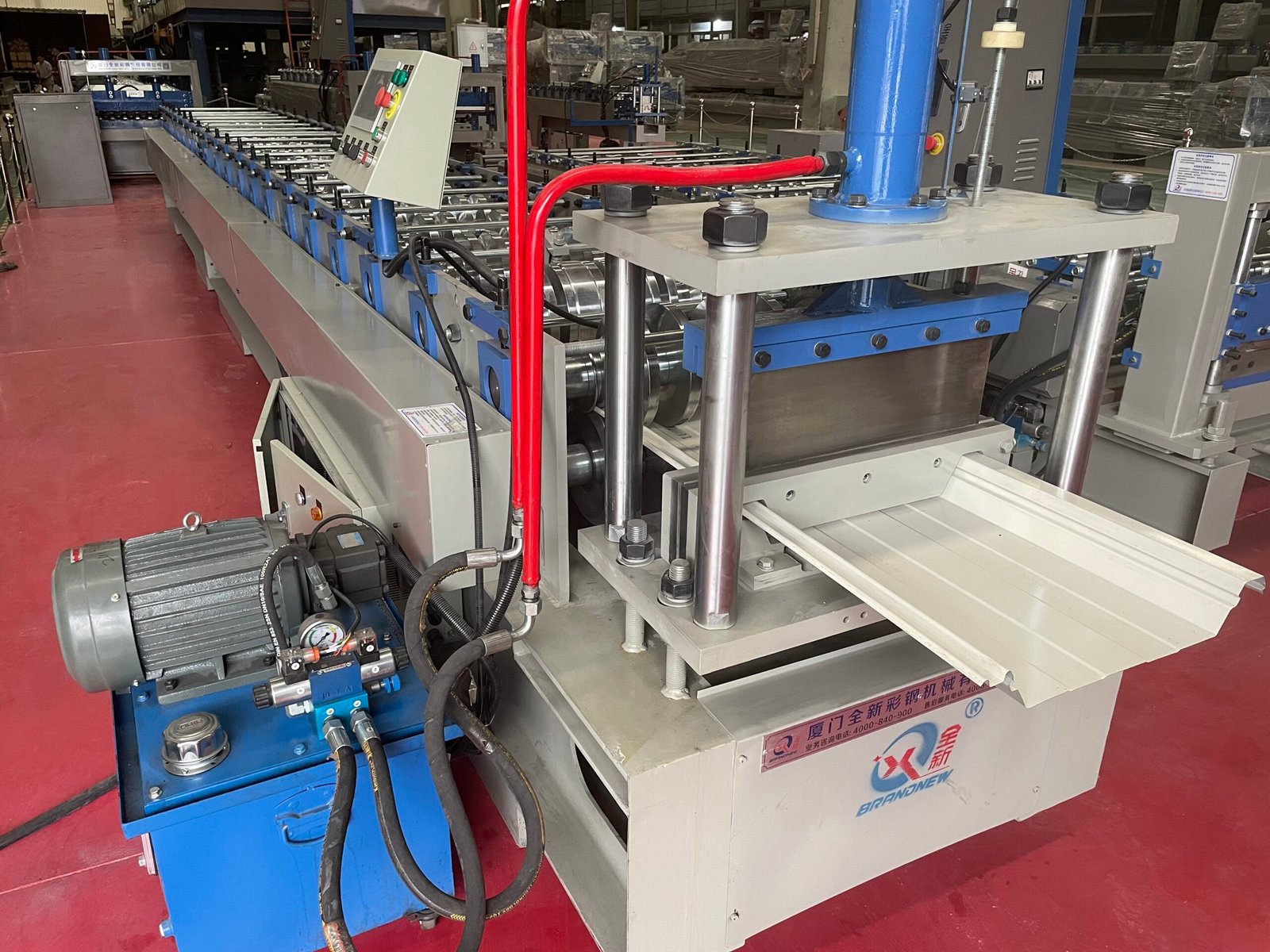

The overall design of this machine favors high quality and efficiency in order to meet the needs of customers processing a wide range of materials, such as galvanized steel, color steel, aluminum-magnesium-manganese plate, etc.

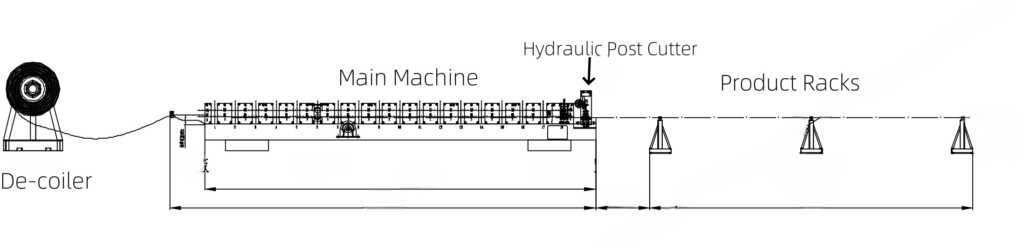

The whole machine set including a de-coiler, steel coil guiding device, front shearer, main roll forming machine, hydraulic post cutter and product racks.

Work flow

Main Components

1.De-coiler

Conventional equipped with a 7T-1300mm simple de-coiler, if necessary, there is hydraulic for option;

2.Coil guiding device

With material feeding guide rollers, and guiding device which is adjustable based on different material width;

3.Front shearer

Normally equipped with manual front shearer, which used to cut the head and tail of the material. According to the customer’s requirements, there is hydraulic shearer for easy operation.

4.Main roll forming machine

Gear/sprocket drive, 25 stations for forming; Shafts material: 45# steel, fine finished; Roller diameter:φ75/85mm, hard chrome plated; Main motor: 11KW, frequency conversion speed control; Forming speed about 16-18m/min;

5.Post Hydraulic Cutter

Post hydraulic cutter, stop to cut, no scrap;

Hydraulic station: 4KW; cutter material: Cr12, heat treatment.

6.Product Racks

Three racks supplied;

Product Pictures

After-Sales Service for Metal Roofing Sheet Making Machine

1)Warranty Coverage

A comprehensive 2 years warranty is provided, complemented by lifetime technical support.

2)Delivery Commitment

Machines are delivered within 25-40 working days after confirming receipt of the deposit payment.

3)Service Guarantee

24 months free maintenance service for all components.

Lifetime paid service available post-warranty, ensuring ongoing assistance for repairs, parts replacement, and troubleshooting.

4)Installation & Training Support

On-site installation guidance and in-person training are offered if clients visit our factory for machine inspection.

Our engineers will train your technicians/workers in machine operation, maintenance, and safety protocols.

FAQ

Q: Are you a trading company or a manufacturer?

A: We are a direct manufacturer with a dedicated production team and export-focused service expertise in cold roll forming machinery.

Q: Can the machine produce only one panel profile?

A: No. Our machines are engineered for multi-profile versatility, supporting wider and dual-layer production capabilities. A single unit can produce 3+ distinct panel profiles with tooling adjustments.

Q: What is the typical lead time for machine production?

A: Standard lead time is 20–45 business days. For urgent orders, we prioritize production to expedite delivery without compromising quality.

Q: How is quality control ensured during manufacturing?

A: Our rigorous QC protocol includes raw material inspection,precision machining of rolls and critical components.

Assembly verification,surface and shaft integrity testing,pre-shipment operational trials and packaging checks.

Q: What if the machine malfunctions?

A:24-month warranty,Free replacement of irreparable parts (customer covers shipping fees).

Post-warranty support: Lifetime technical assistance and negotiated repair solutions.

Q: What differentiates you from competitors?

A: Our strengths include customer-centric service with tailored engineering solutions.

Low-maintenance, user-friendly designs for quick installation and operation.

Value-added guidance to optimize your ROI and product performance.

Q: Can we partner as your international agent?

A: Absolutely! We actively seek collaborations with distributors or agents to sale our roll forming machine.

Item | Parameters |

Material | 0.4-0.7mm galvanized steel, color steel, aluminum-magnesium-manganese plate |

Material Feeding Width | 1200mm |

Driving Motor | 11KW |

Hydraulic Motor | 4KW |

Machine Frame | H350 Steel Base, 18mm thickness wall plate |

Shafts Diameter | Φ75、85mm |

Roller Material | 45# steel,fine-finished,heat treated and outer surface planting |

Forming Station | 25 stations |

Forming Speed | 16-18M/Min |

Related Products

Request A Quote

If you have any questions or require more detailed information about our roll forming solutions, please contact us by clicking on the link below.

Our product specialists will be in touch with you shortly to discuss your requirements!