Floor Deck Roll Forming Machine

Floor Deck Roll Forming Machine

Floor Deck Roll Forming Machine

Floor deck roll forming machine is used to manufacture metal floor decks. Metal floor deck has uniform quality and an attractive look with proper coatings. With a multitude of benefits like strength, light weight, being cost – effective, and simple installation, it serves as the perfect building material for architects, building owners, and engineers.

Used for roofs and floors, steel deck sheets support gravity loads between joists and beams. The floor decking machine includes an uncoiler, coil sheet guiding equipment, a roll-forming mill, a post-cutter, a hydraulic station, a controlling system, and product run out table. The general work flow of this kind of machine set is as follow:

De-coiler — Feeding Guide/Strengthening — Pre-cut — Roll Forming Mill — Embossing Pressing Device(If required) — Hydraulic Post Cutting Device — Exit Rack*3

Main Components Of The CZ40040 Purlin Machine

1.Decoiler

Type:Manual decoiler or hydraulic decoiler

Load capacity:7T

Coil inner diameter:480-580mm

Main Types of Floor Deck Roll Forming Machine

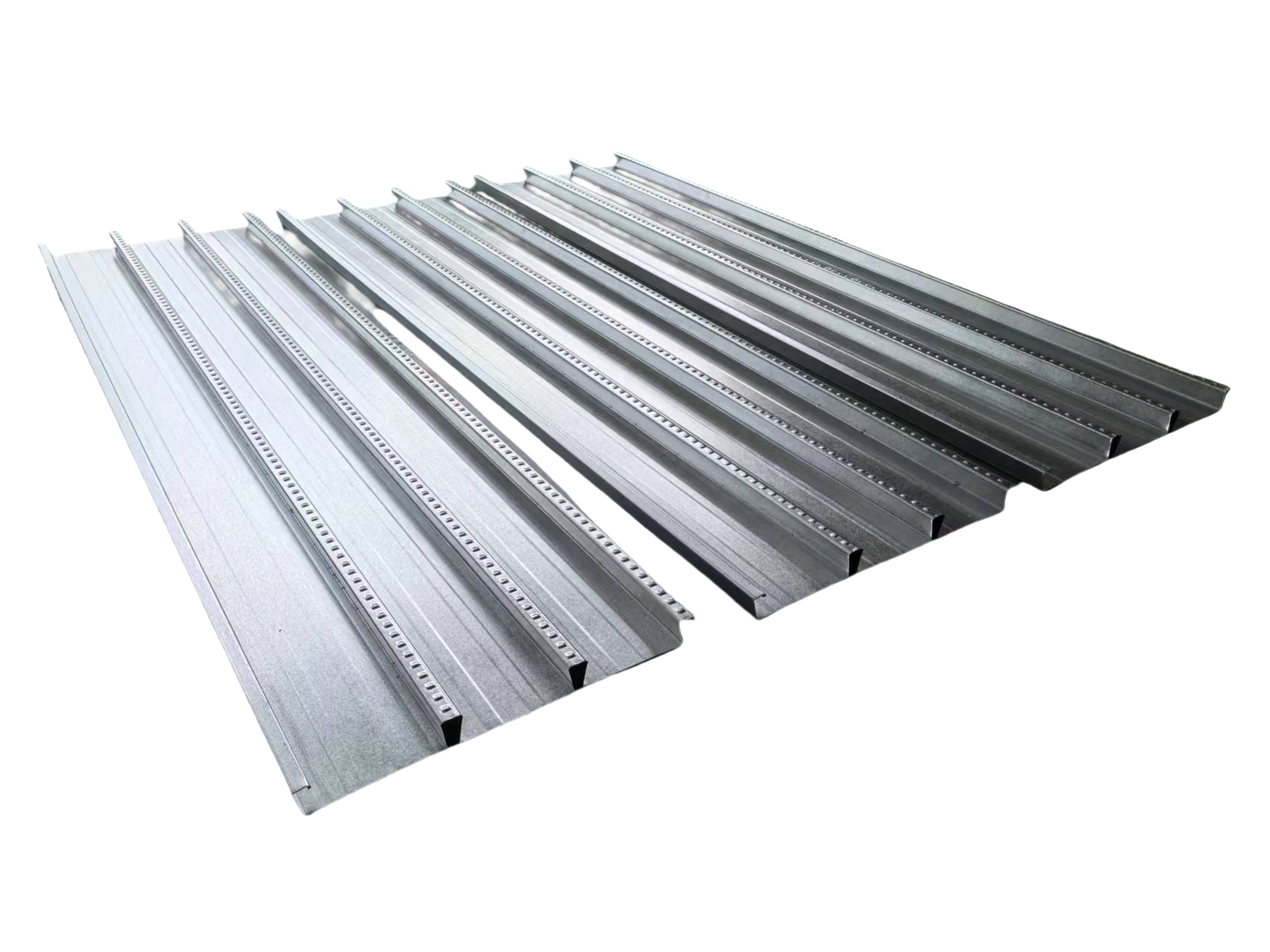

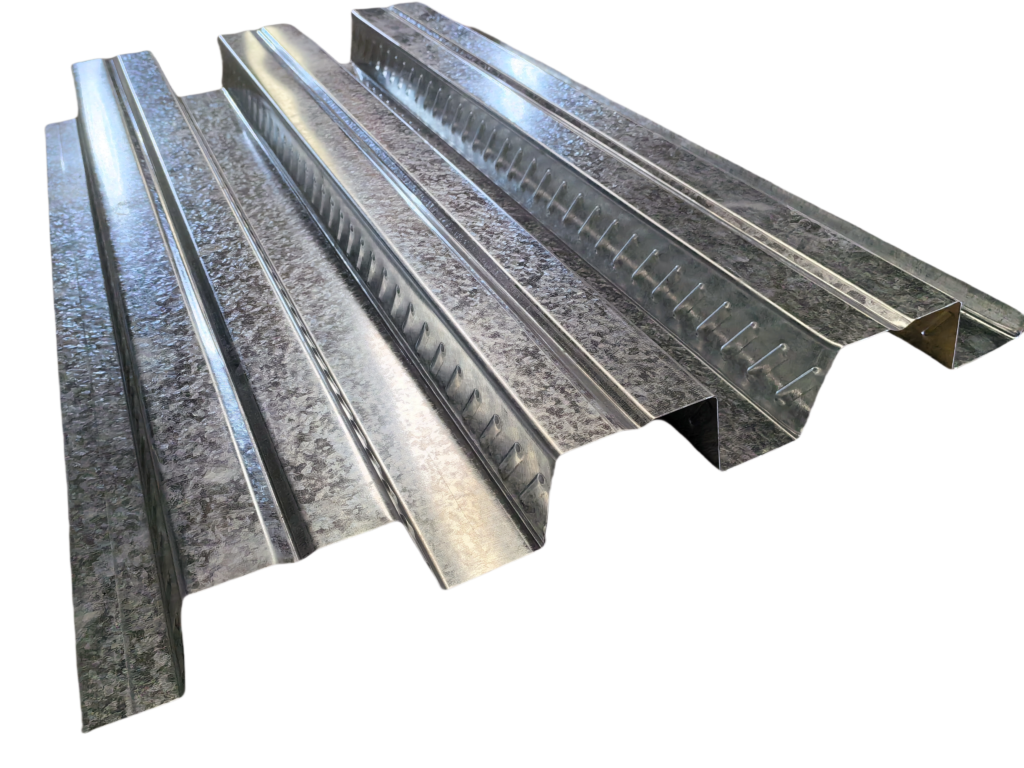

◈Composite Floor Deck Roll Former

Its main function is to manufacture metal deck panels, which are extensively used as form work or support surfaces for concrete slabs in buildings, bridges, and other structures. Usually made of steel or other metals, these panels provide a robust platform for concrete pouring.

The roll-forming process entails feeding a continuous metal strip through a series of rollers and dies to gradually shape it into the desired profile. A composite metal deck roll forming machine is configured to create panels with the specific dimensions and features needed for a particular construction project.

Key features and functions of composite floor deck machine include:

Material Feeding: It has a system for feeding coil or sheet metal, ensuring a continuous supply of material for the forming process.

Roll Forming Stations: Multiple stations with sets of rollers and dies are used to progressively shape the metal into the required deck panel profile, including its shape and size.

Cutting and Shearing: Many machines are equipped with a mechanism to trim the formed panels to the appropriate length.

Control System: A control panel or computerized system allows operators to set panel dimensions and control the machine’s operation.

Safety Features: Guards, emergency stop buttons, and safety interlocks are often included to ensure safe operation.

The design and capabilities of these machines vary according to the manufacturer and end – user requirements. They are essential in the construction industry as they efficiently produce metal deck panels for various building and infrastructure projects.

Composite Deck Profile

Thickness: 0.8-1.5mm;

Suitable for GI, stainless or aluminum sheet;

Feeding Width: 1000mm, 1220mm, or customized;

Effective Width: 688mm,750mm,915mm, 1000mm or customized;

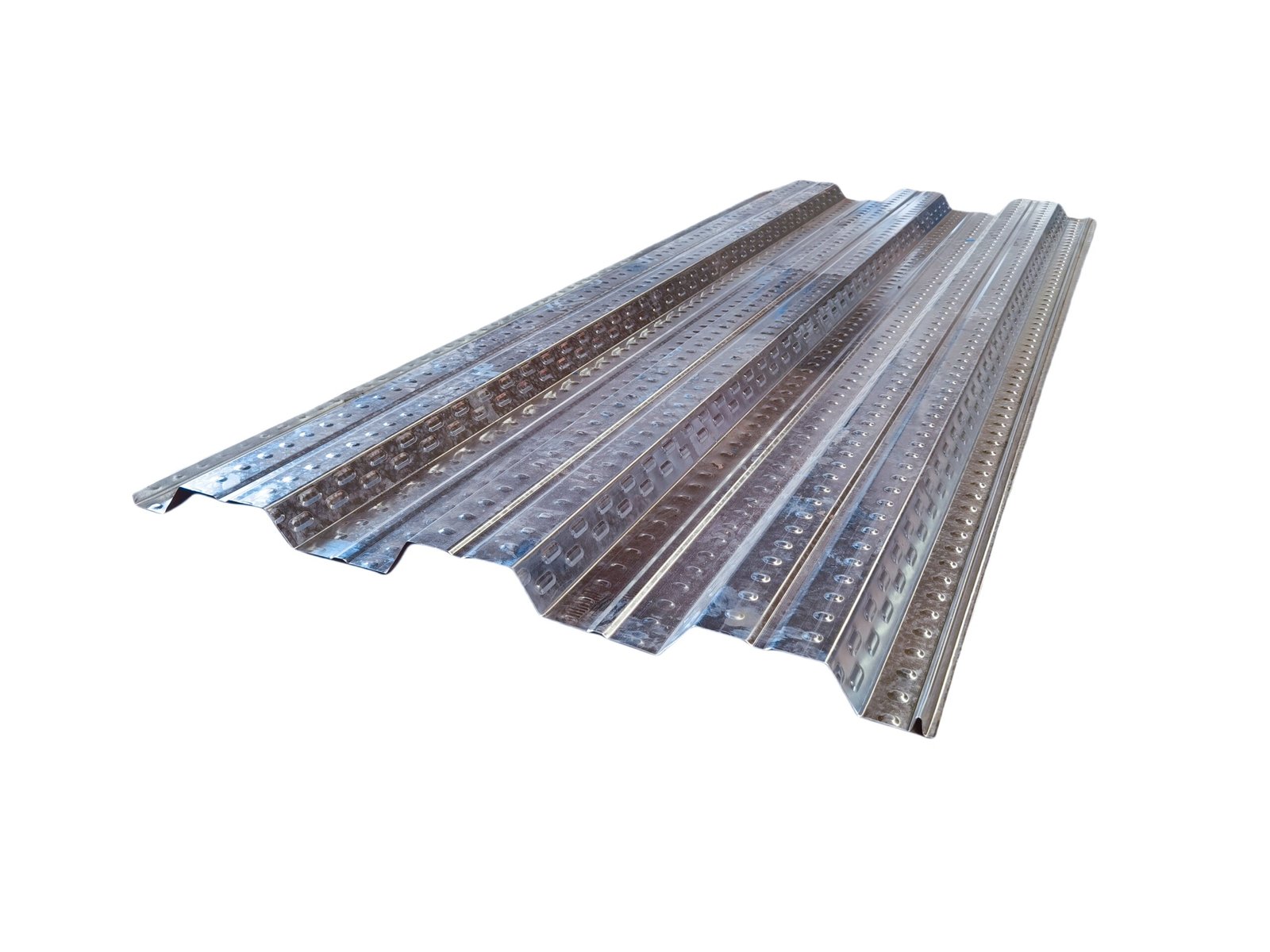

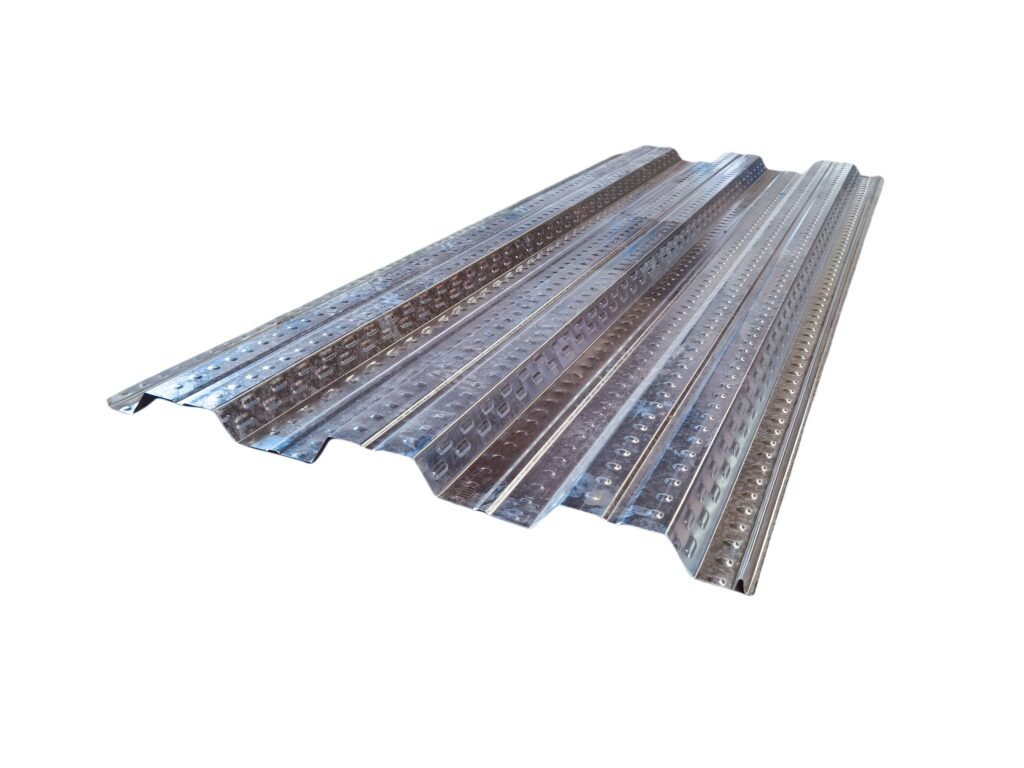

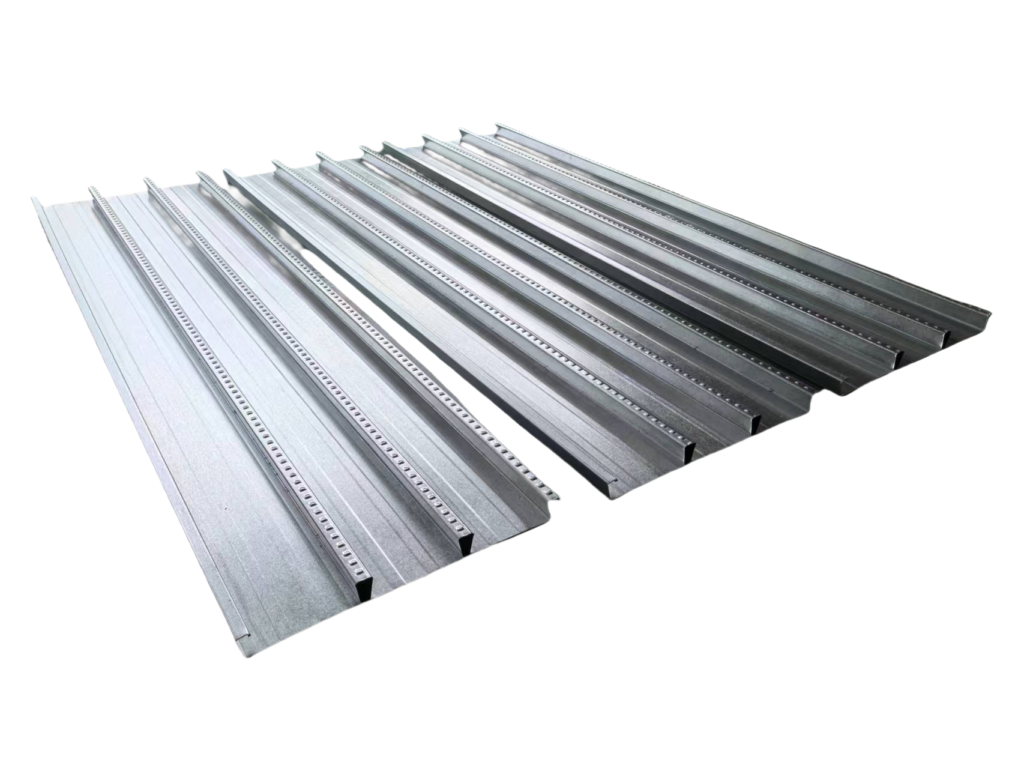

◈B Decking Roll Forming Machine

- Deck roll forming machine is a piece of equipment designed to produce metal roof deck panels known as “B-Deck.” B-Deck is a type of corrugated metal deck commonly used in construction for structural support and as a base for roofing systems.

Here are some key features and details you might expect from a B-Deck roll forming machine:

Material Compatibility: The machine is designed to work with specific types of metal coils, such as galvanized steel, stainless steel, or aluminum, depending on the project requirements.

Roll Forming Process: Roll forming is the primary process used by these machines. It involves passing a flat metal strip through a series of rolls to gradually shape it into the desired corrugated profile.

Cutting Mechanism: The machine uses a Hydraulic Shear cutting mechanism to cut the formed metal deck panels to the required length

Control System: All roll forming machines come with computerized control systems for precise control over the forming process. This allows for customization and accuracy in producing deck panels of consistent quality.

Speed and Production Capacity: The production speed and capacity of the machine depend on various factors, including the material thickness, and the specific design of the machine.

B Decking Profile

Thickness: 0.8-1.5mm;

Suitable for GI, stainless or aluminum sheet;

Feeding Width: 1000mm, 1220mm, or customized;

Application: roof, floor, and mezzanines

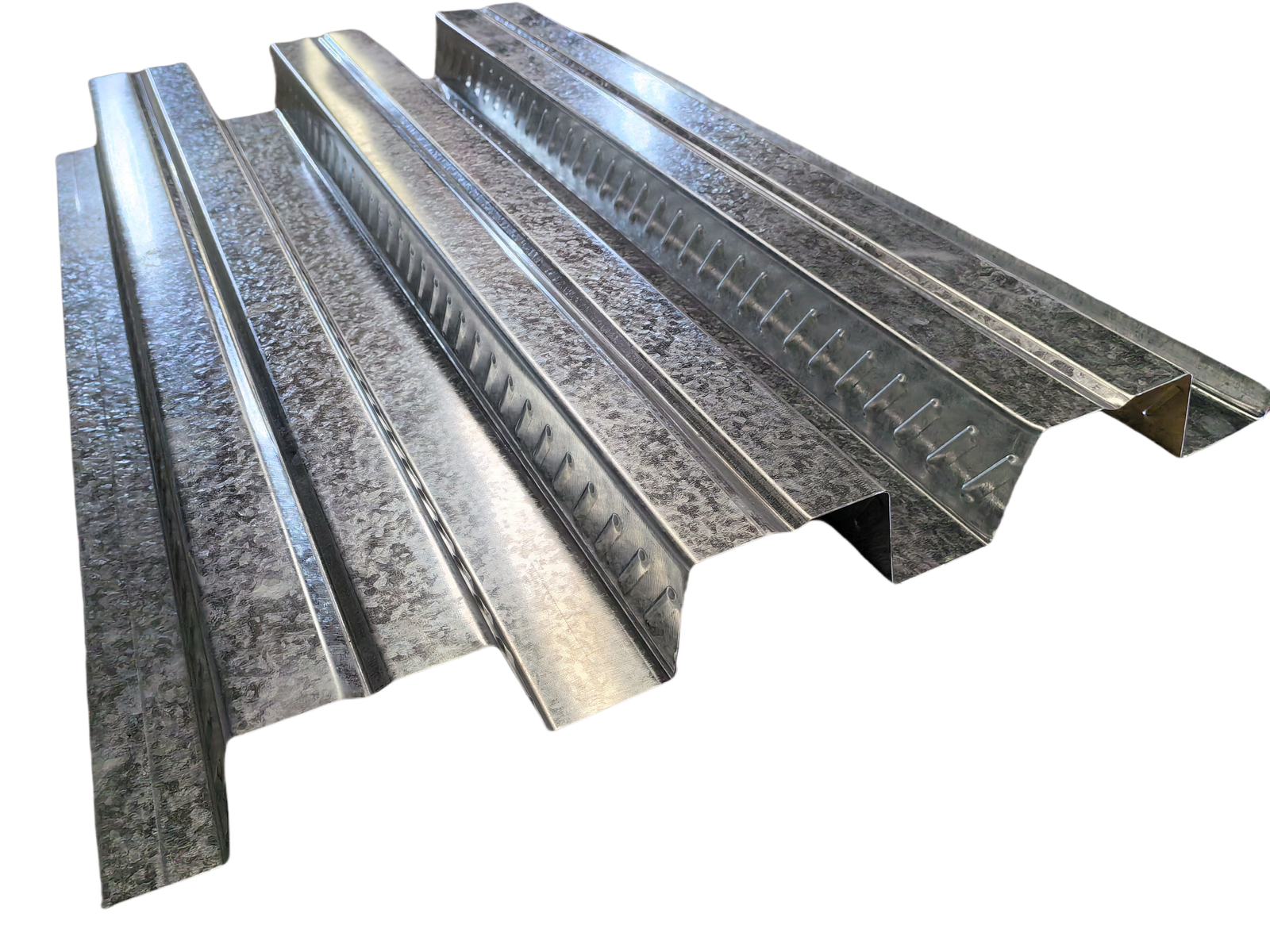

◈Dovetail Decking Roll Forming Machine

What is Dovetail Decking?

The standout feature of its dovetail – shaped profile is that the panel’s underside presents a finished ceiling appearance. This also makes it a practical choice for mounting lighting, HVAC, plumbing, or electrical systems.

Dovetail decks can be used for both floors and roofs, especially when the span between supports exceeds 3048mm to 7620mm for a shallow floor depth is needed. The unique profile of dovetail decking not only provides high strength and load – bearing capacity over long spans but also offers an aesthetically pleasing underside for exposed ceilings, making it a highly efficient and valuable addition to roof systems. Typically, it features a lower rib height, ranging from 40 to 60mm, and a relatively small rib spacing. This unique design significantly boosts the overall stiffness of the floor slab.

This dovetail decking roll forming machine is built to handle high – tension galvanized steel coils. It has a total of 36 stations. After the roll – forming process by these stations, the produced floor decks have precise dimensions. The entire surface of the plate is straight and won’t deform easily. All the rollers in the machine are precisely processed. After a specific treatment, they are coated with hard chrome, which makes them long – lasting and rust – resistant.

Dovetail Deck Profile

Thickness: 0.8-1.5mm;

Suitable for GI, stainless or aluminum sheet;

Feeding Width: 1000mm, 1220mm, 1250mm ;

Effective Width: 600mm, 820mm, 850mm

Related Products

Request A Quote

If you have any questions or require more detailed information about our roll forming solutions, please contact us by clicking on the link below.

Our product specialists will be in touch with you shortly to discuss your requirements!