Cable Tray Roll Forming Machine

Cable Tray Roll Forming Machine

Cable Tray Roll Forming Machine

Beenew cable tray roll forming machine is a highly efficient and versatile piece of equipment designed for manufacturing building-use cable trays. This machine is equipped with an uncoiler, a hydraulic punching and cutting system, and a width-adjustable roll forming system.

Capable of handling materials with a thickness ranging from 1mm to 2mm, our cable tray roll forming machine can produce cable trays of various specifications. For cable trays with a width typically within the range of 100mm to 600mm, the height can be set between 50mm and 100mm.When the width of the cable tray is from 600mm to 900mm, the height is fixed at 50mm.

One of the key features of our machine is its automatic width adjustment function, which greatly simplifies the production process and enhances production efficiency.

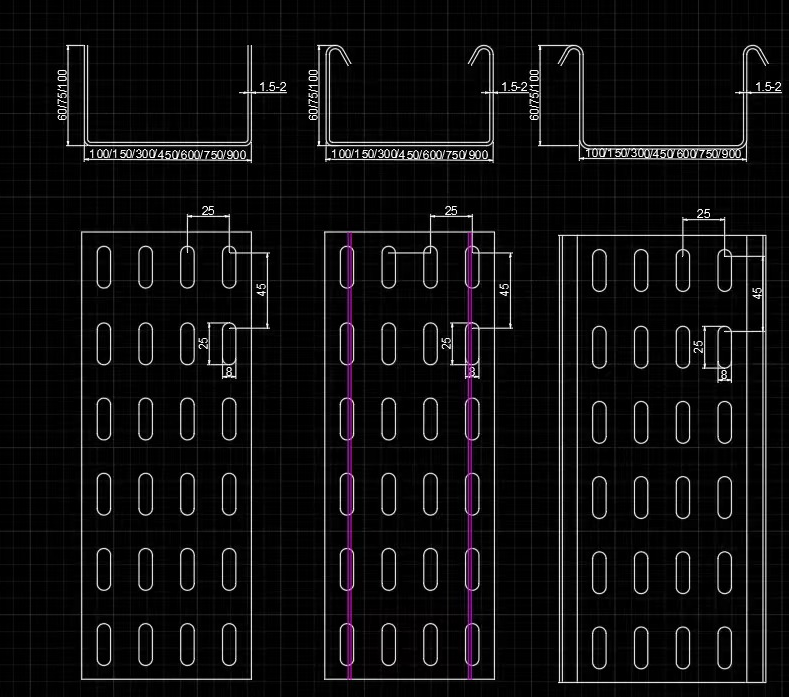

Profile drawing

Material

Thickness: 1.5~2mm

2mm thickness is for inspection, common use

Effective width: 100-500mm

Height: 60/75/100mm

Coil Width for this profiles: Accroding customer requiment

Galvanized steel, Tension Grade: 345Mpa

Main Components

1.Decoiler

2.Leading/Straightening Device

9 rolls straightening, levelling roll diameter: 95mm

Leading motor: 15KW

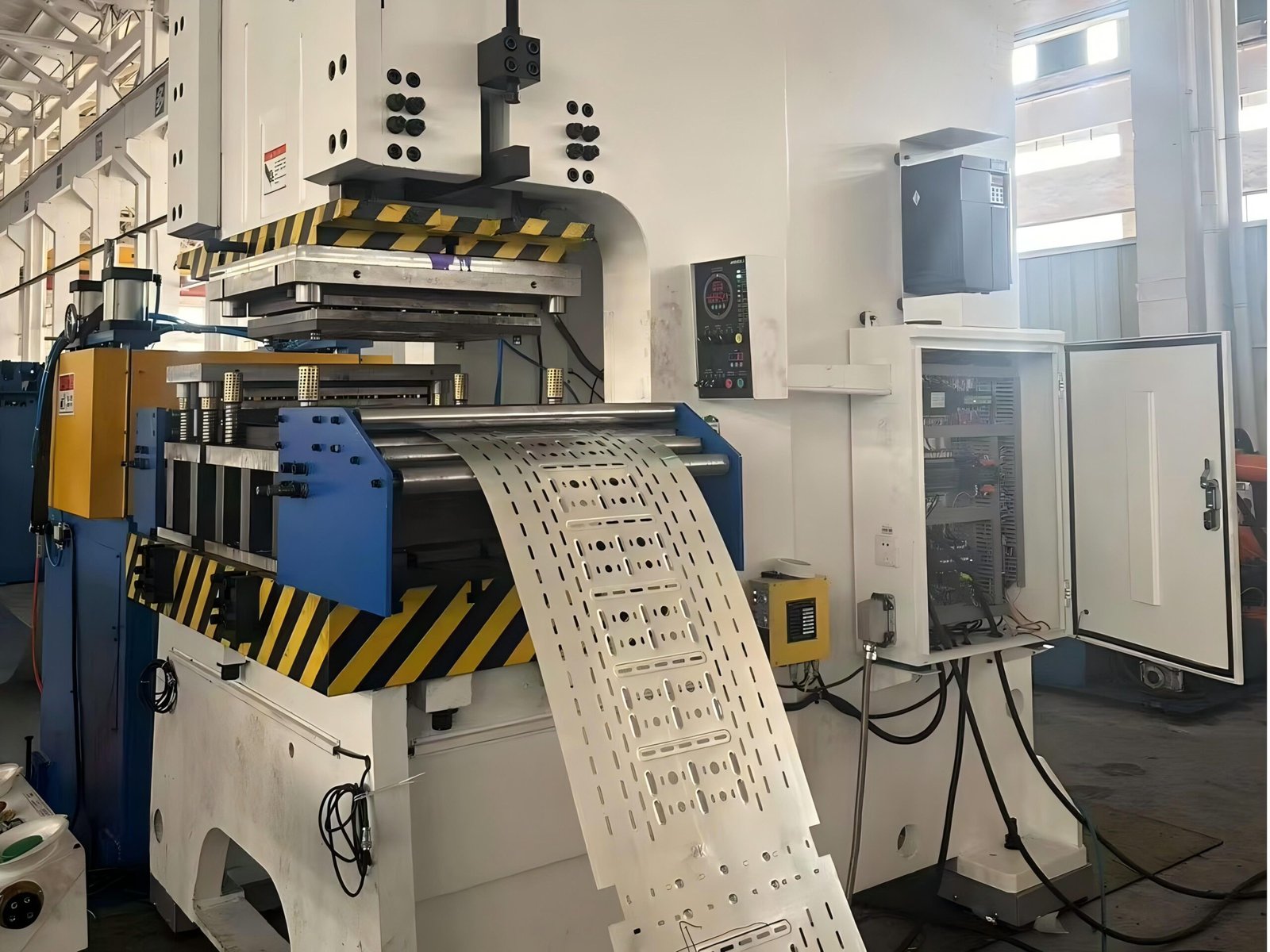

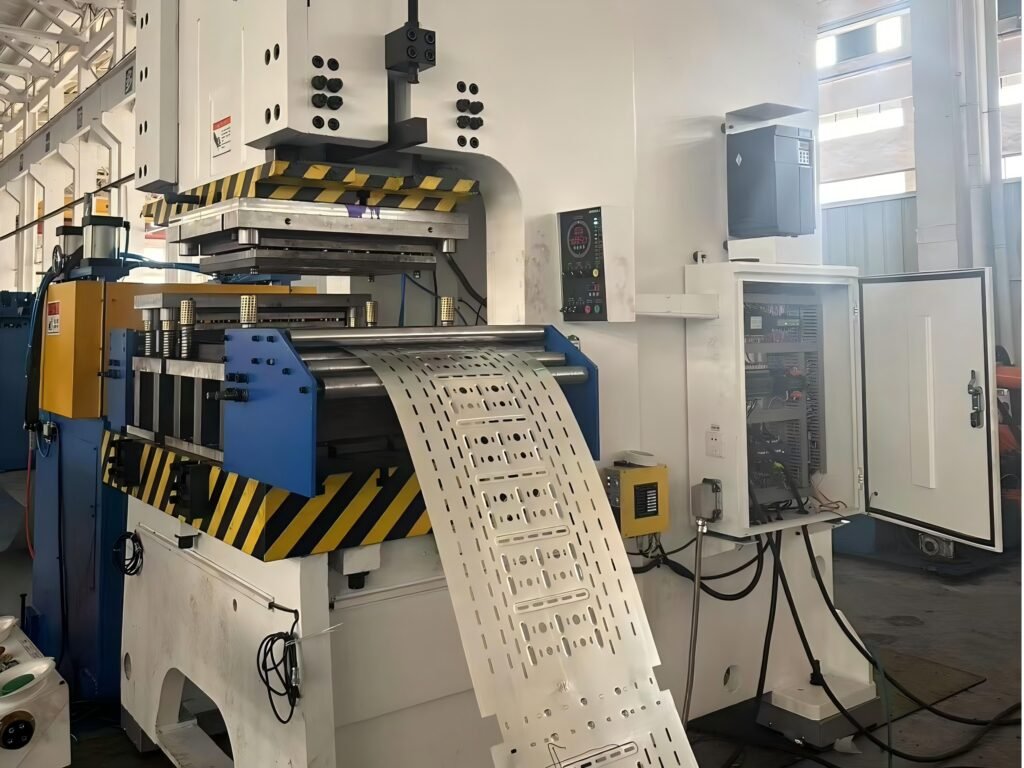

3.Servo Feeding/Punching Machine

Servo motor feeding, servo motor punching

Punching machine capacity: 315tons

With full set punching dies slot 8mmx25mm, slots 25mmx45mm

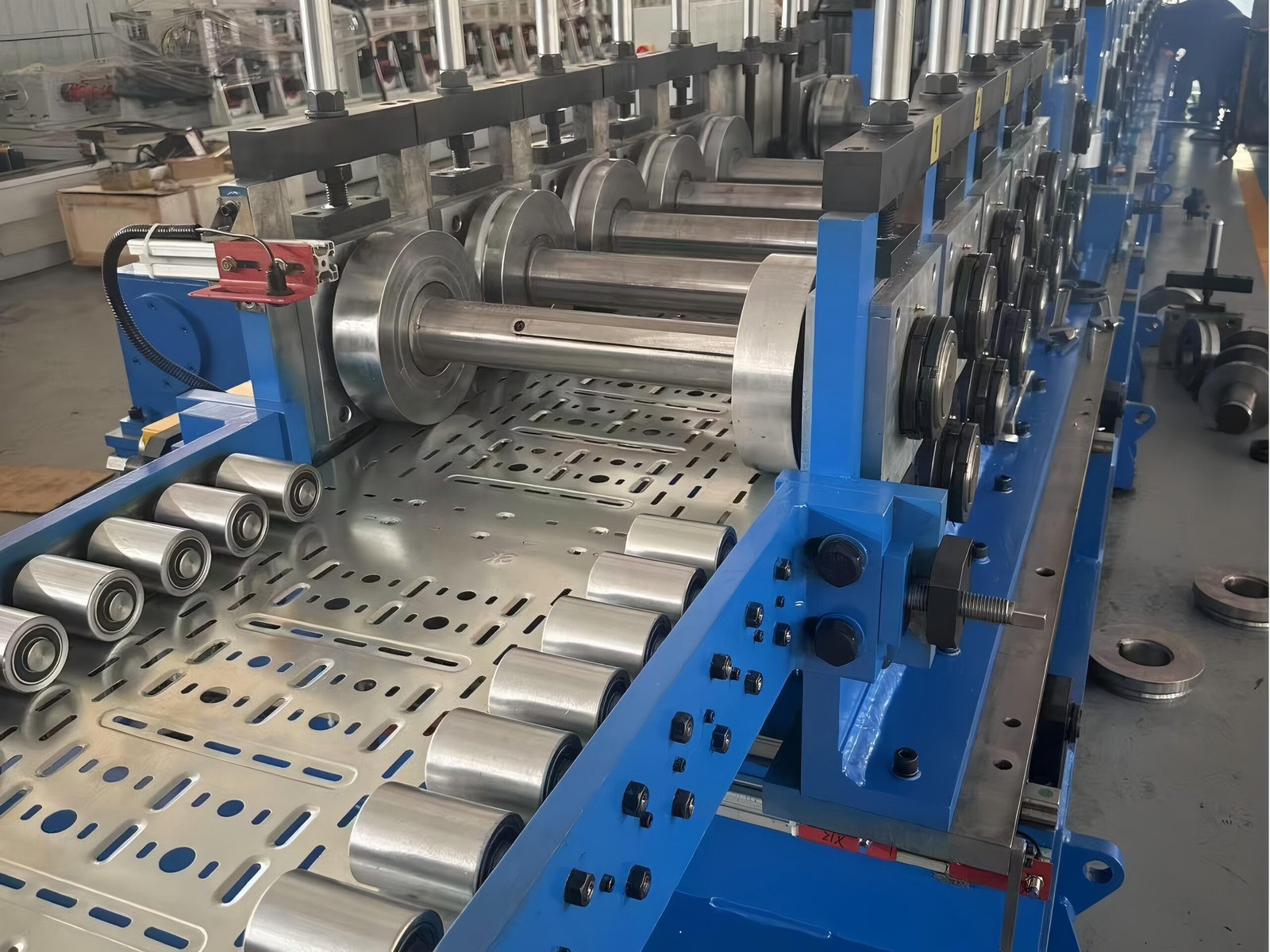

4.Cold Rolling Mills

Feeding section with guide

Gear/Sprocket driving

18-step to form+2-step for height type changing+3-step shaping

Rollers manufactured from Cr12, CNC lathes

Shafts Diameter=ф100/85mm, Precision Machined

Main motor =30KW(servo motor), Frequency speed control

Forming speed:Approx. 23-25m/min(without punching&cutting actions)

Size interchangeable from 100-500mm

Side wall thickness: 40mm

Machine frame: H500

5.Hydraulic cutting device

Pump motor =11KW

Cutting pressure=Max.15Mpa

Stop to cut, post, no blanking cut

Cutting tool material: Cr12, Heat treatment

Cutting width is adjustable, different height changes different cutting blades

Matches with total 2pcs upper cutting blades (one pcs for U100-300, other pcs for U300-500)

6.PLC Control System

Control the punching,cutting length & quantity automatically

Combined with:PLC, inverter, Touch Screen, Encoder, etc

Cut-to-length tolerance≤±2 mm

Control voltage 24V

7. Product rack

Un-powered, 4 units

Item | Parameters |

Driving Motor | 30.0KW |

Forming Speed | 23-25m/min |

Roller Material | CR12 |

Shaft Diameter | φ100/85mm |

Shaft Material | 40Cr round steel quenching and tempering treatment |

Pump Motor | 11.0KW |

Cutting Type | Hydraulic Cutting |

Control System | PLC |

Machine Frame | H500 |

Related Products

Request A Quote

If you have any questions or require more detailed information about our roll forming solutions, please contact us by clicking on the link below.

Our product specialists will be in touch with you shortly to discuss your requirements!