C Purlin Roll Forming Machine

C Purlin Roll Forming Machine

Description

C Purlin Roll Forming Machine

Beenew C30030 C Purlin Roll Forming Machine – Engineered for precision, delivering high-stability, high-capacity performance.

Designed for effortless operation, it minimizes downtime while adapting to widths (100-300mm) and thicknesses (1.5-3.5mm). Robust construction ensures long-term reliability, ideal for diverse manufacturing applications requiring consistent quality and efficiency.

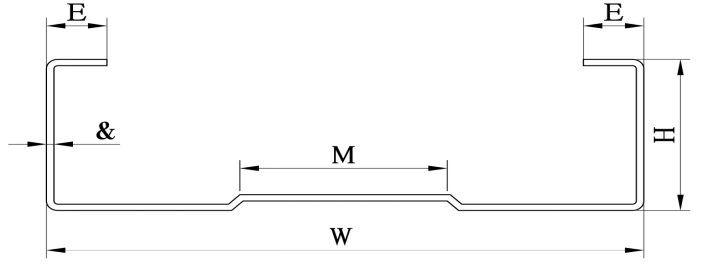

Profile drawing

C Purlin Machine Flow Chart

Uncoiler- Pre-Shearer- Flattening & Guiding -Z Purlin Main Roll Forming Machine – Hydraulic Punching – Post Cutter -Product rack

Main Components Of The C Purlin Machine

1.Decoiler

Type:Manual decoiler or hydraulic decoiler

Load capacity:6T

2.Flattening and Guiding System

Flattening system: Upper 3 and lower 4 rollers plus additional pressure rollers are used to level the steel coils

Guiding system:Equipped with a guiding shaft and guiding rollers, its width can be adjusted to accommodate various steel strips.

Machine shaft: 40Cr quenched and tempered

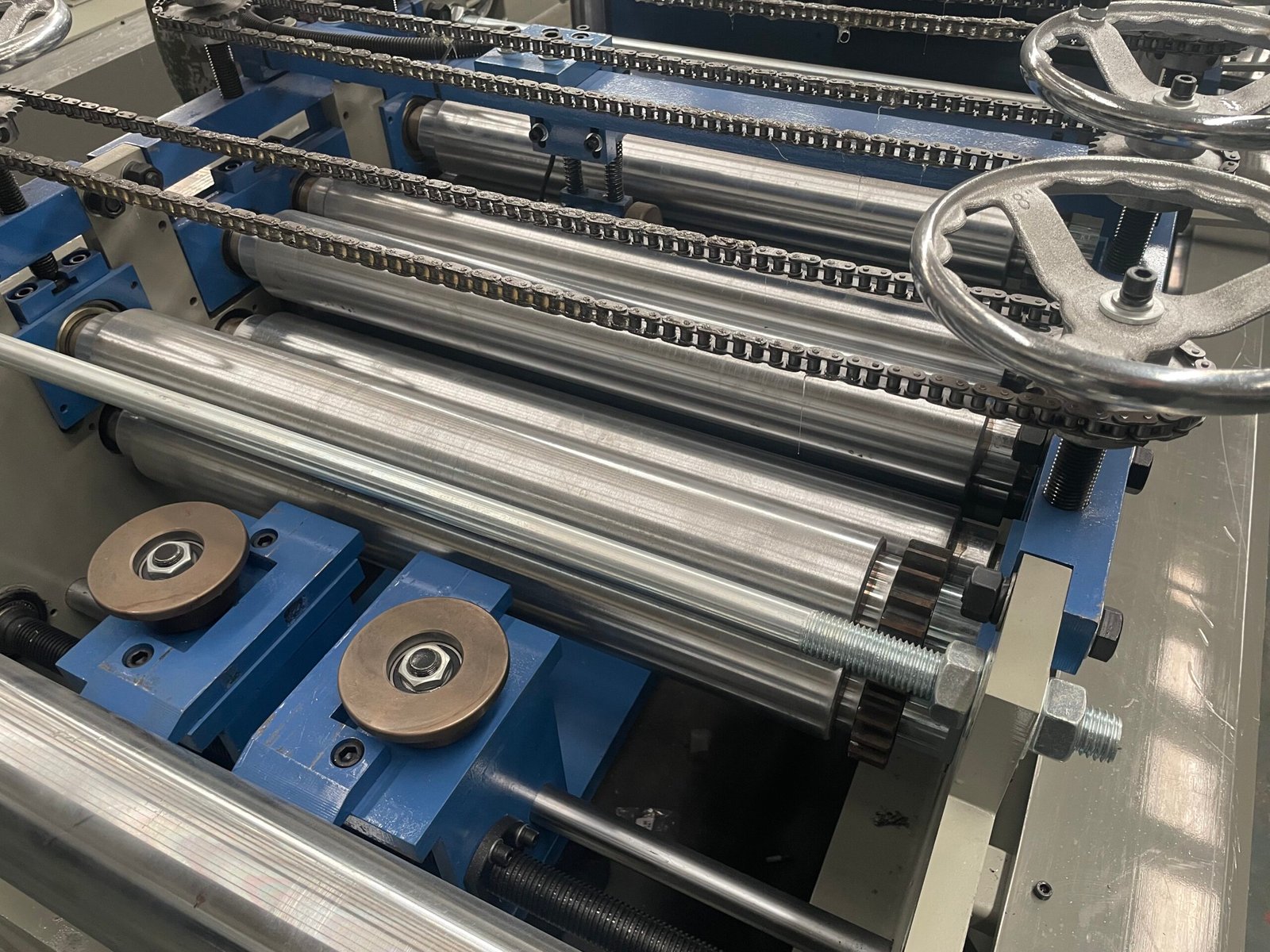

3.Main Z roll forming machine

Forming stand:14 stations

Roller material: flat wheel Gcr15 bearing steel/slant wheel Cr12 mold steel

Transmission type:chain drive+gear/sprocket drive

Mchine base:Welded using H400 plate, undergoes shot blasting and heat treatment processes

Roller material: flat wheel Gcr15 bearing steel/slant wheel Cr12 mold steel

Z purlin machine main drive: servo motor

Machine shaft: 40Cr quenched and tempered

Purlin size adjustment: continuous adjustment through PLC control and touch panel settings

Purlin Straightening Unit:Two-axial straightening units with 10 rollers, along with 4-roller axial straightening units. These are designed to guarantee that the purlin will not experience curving, bowing, sweeping, or twisting

4. Hydraulic punching

Punching unit configuration: 2 sets

Punching type: A post-punching unit and an automated punching mechanism

5. Post cutter

Type:Adopts post-cutting technology,automatically cut the material to the specified length and quantity

Cutter material:Cr12Mov mold steel wire cut and heat treated

6. Power supply & Control System

Control cabinet: 1 sett,with an ’emergency stop’ switch

Control handle: 1 set of control handle is provided

Operation platform:HMI and buttons,has an English language display

7. Product rack

Type :2 sets, 3 meters each, free roller type

Overview of other optional systems

Inkjet printing system: custom printing of company name, corporate logo, product code, etc. on purlin flanges

Pre-cutting mechanism: quick change of steel coils without affecting production flow

Flat plate pre-punching equipment: pre-punching and slotting operations

Automated stacking system: stacking of processed C-shaped purlins

Additional punching unit: supports additional installation of punching devices

Main advantages of C purlin machine

High degree of machine automation: fully automatic purlin size adjustment

Wide range of steel and purlins: raw material types can be galvanized steel, black steel.

Universal cutter: Suitable for all C, Z and U purlin sizes

Quick change: Quick C purlin size within 2 minutes

Through shaft design: Reduces uneven height caused by machine spindle breakage

High-strength structure: Made of cold-pressed high-strength steel plate, uniform wall thickness and high compressive strength

High precision: High plate shape accuracy, easy adjustment of length offset and purlin punch position

Specification

Item | Parameters |

Driving Motor | 22.0KW |

Forming Speed | 30m/min |

Roller Material | GCR15 |

Shaft Diameter | φ80/65mm |

Shaft Material | 40Cr round steel quenching and tempering treatment |

Pump Motor | 7.5KW |

Cutting Type | Hydraulic Cutting |

Control System | PLC |

Punching group | 2 sets |

Video

Inquiry

Related Products

Request A Quote

If you have any questions or require more detailed information about our roll forming solutions, please contact us by clicking on the link below.

Our product specialists will be in touch with you shortly to discuss your requirements!