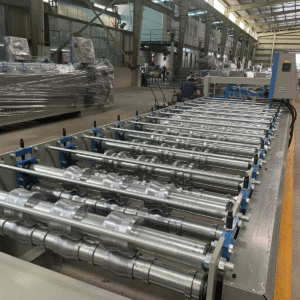

IBR Manufacturing Machine

IBR making machine is very popular in African market, such as Zimbabwe, South Africa

Showing 19–27 of 36 results

IBR making machine is very popular in African market, such as Zimbabwe, South Africa

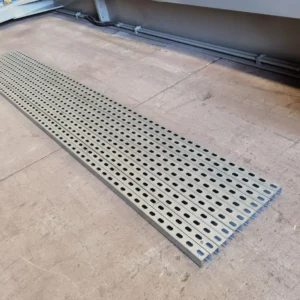

Angle profile is not the main load-bearing part in warehouse racking systems.

It is not used as uprights or beams, but as an important auxiliary, reinforcing, and connecting role in racking systems

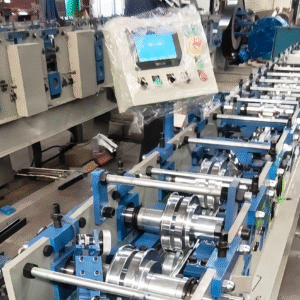

This gutter machine is designed to deal with 0.5-0.8mm thickness PPGI coils. Totally 17 steps to form and the forming speed is about 18-20M/min.

High quality and reasonable price, Beenew roll forming machine provide guarantee for your steel rolling shutter door business.

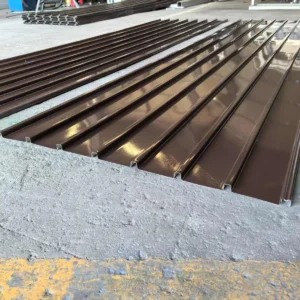

Sheets produced by this metal roofing sheet making machine are of simple but modern outlook. Because of its shape characteristics, it is very good at bearing weight and strength.

This machine is a complete automated line that turns metal coils into strong, ready-to-use shelf panels. It shapes the metal, adds supportive ribs for strength, and cuts it to size—all in one continuous, high-speed process.

Beenew Machinery’s Solar C&U Channel Roll-Forming Line: An Intelligent Manufacturing Solution for High-Precision Photovoltaic Structural Profiles.

The Beenew Machinery-developed Solar C&U Channel Roll-Forming Line is a dedicated manufacturing system for high-precision structural profiles for the global photovoltaic industry.

Beenew standing seam roll forming machine is available in multiple configurations, compatible with diverse roofing profiles such as corrugated sheets, IBR panels, glazed tile sheets, and self-lock roofing systems.