Trapezoidal Sheet Roll Forming Machine for R101

Trapezoidal roof panel forming machines, as core equipment for producing trapezoidal roof panels, occupy an important position in the building materials industry, especially in countries such as Mexico, Costa Rica, Honduras, Guatemala, and Colombia.

Description

Trapezoidal Sheet Roll Forming Machine

Trapezoidal roof panel forming machines, as core equipment for producing trapezoidal roof panels, occupy an important position in the building materials industry, especially in countries such as Mexico, Costa Rica, Honduras, Guatemala, and Colombia. With their stable performance and wide applicability, they have become the preferred equipment for local steel structure buildings, factory construction, and other projects, providing strong support for the efficient supply of roofing materials.

This equipment demonstrates exceptional flexibility in raw material adaptation. The R101 model is compatible with a 1220mm feed width, while the R72 model is compatible with a 914mm feed width. Production can be switched simply by changing the raw material width, without adjusting the equipment structure. Regarding panel thickness, it can process raw materials from 0.3-0.7mm (i.e., gauge 23-30), again meeting different thickness requirements without changing the equipment. Furthermore, the equipment is compatible with materials with yield strengths of 235Mpa-550Mpa and can produce trapezoidal panels of any length, fully adapting to diverse construction needs.

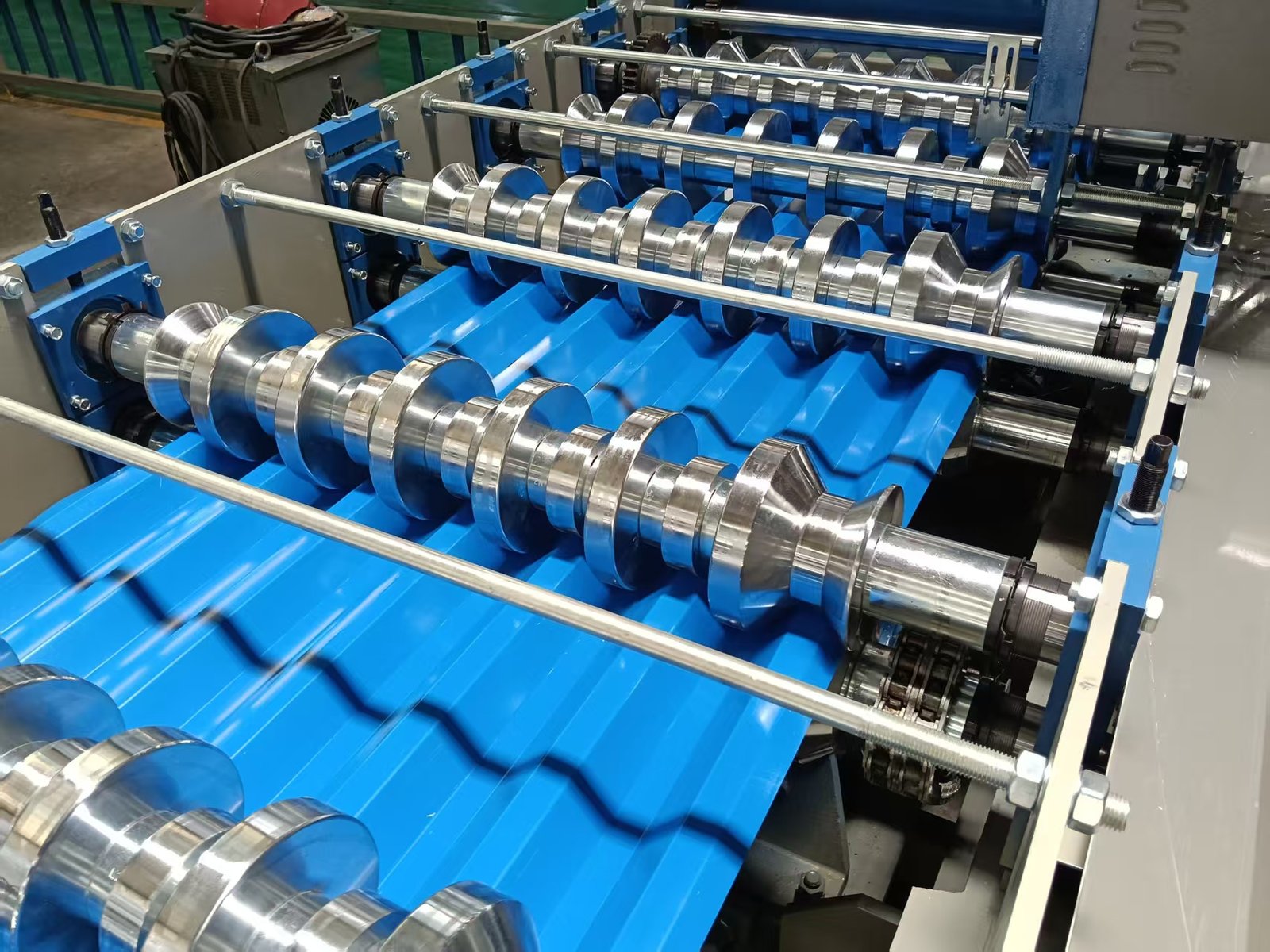

Main roll forming machine

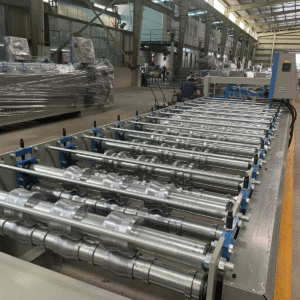

The core configuration of the equipment ensures production stability, mainly consisting of a 5-ton manual uncoiler, a forming main unit with post-shearing function, a PLC controller, a hydraulic station, and a discharge platform. These components work together to build a complete and efficient production line, achieving seamless integration from raw material uncoiling and forming to shearing and discharge, significantly improving production efficiency.

PLC

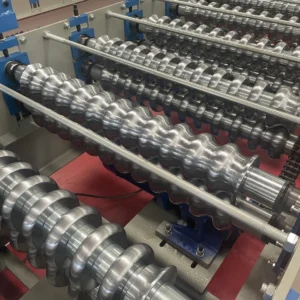

High precision and high automation are the outstanding features of this equipment. It adopts a Mitsubishi or Siemens control system to achieve fully automated and precise production. Combined with the scientific design of 26 rolling stations, it effectively ensures the flatness and precision of the R101 trapezoidal plates. The equipment weighs approximately 11 tons, with a stable structure, providing reliable assurance for long-term continuous production and reducing product errors caused by equipment vibration.

The convenient installation process further lowers the barrier to entry. The production line has been installed and debugged before leaving the factory. Customers only need to connect some lines and pipes according to the video tutorial and instruction manual to quickly start the equipment and put it into production, significantly shortening the equipment commissioning cycle and saving customers valuable time and labor costs.

Reviews

There are no reviews yet.