Shelf Rack Roll Forming Machine

This machine is a complete automated line that turns metal coils into strong, ready-to-use shelf panels. It shapes the metal, adds supportive ribs for strength, and cuts it to size—all in one continuous, high-speed process.

説明

Shelf Rack Roll Forming Machine

Warehouse racking serves far more than just “shelves for storing things.” It’s a core infrastructure element of modern logistics systems, acting as the “skeleton” connecting production, warehousing, and distribution. The design of the racking directly determines how much inventory a warehouse can hold, its operational efficiency, and the overall level of management.

A complete warehouse racking system is primarily assembled from several parts: uprights, beams, support beams, and shelves. These components are now mostly manufactured using an advanced process called “roll forming.” The uprights are the most critical load-bearing part of the racking system. Using roll forming machines allows for the efficient production of sturdy uprights with multiple rows of perforations, making it the most mainstream and efficient production method currently available.

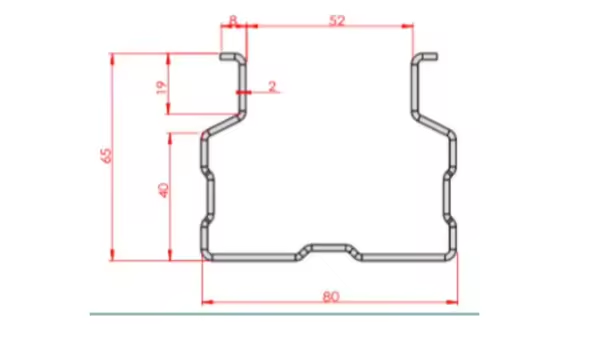

Profile

Details

Material:Suitable for 1.5-2.0mm thickness, 235-350MPA coil

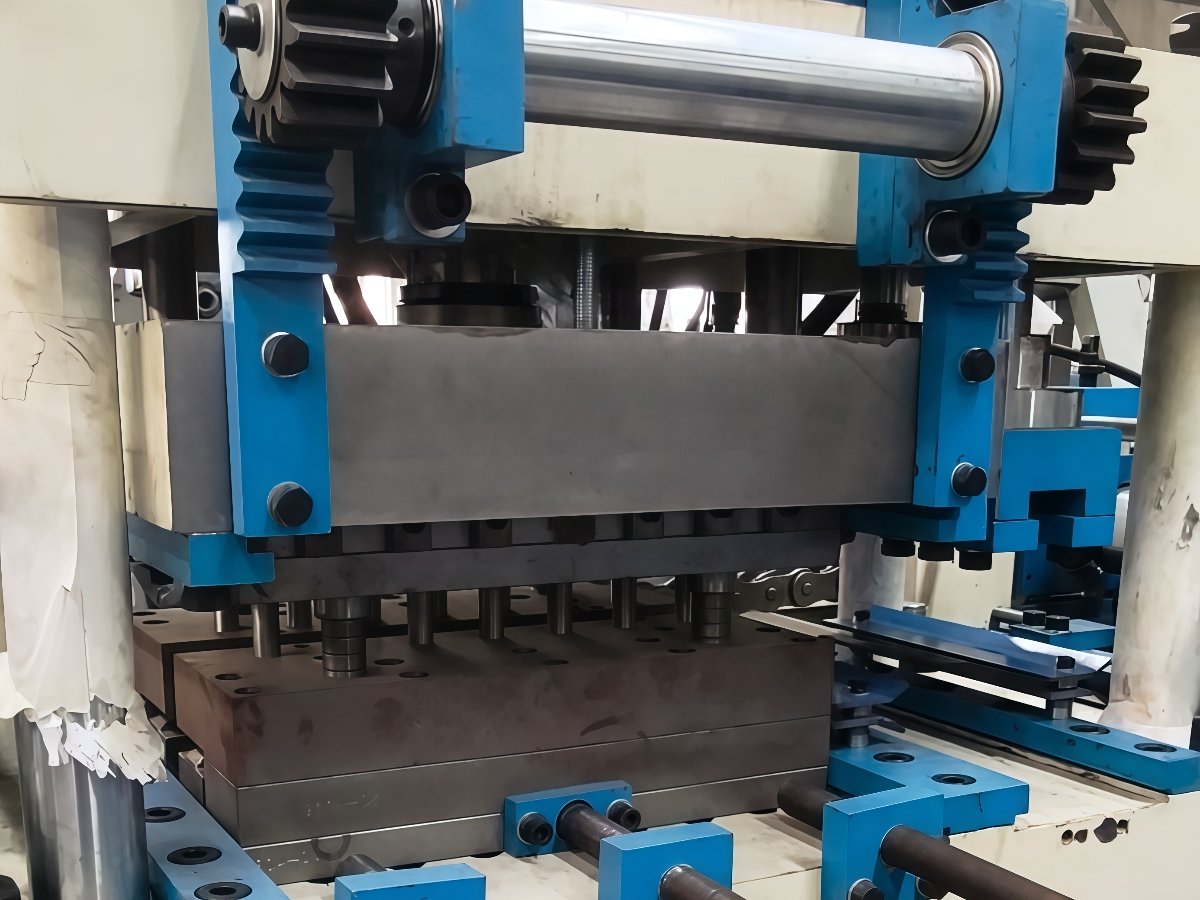

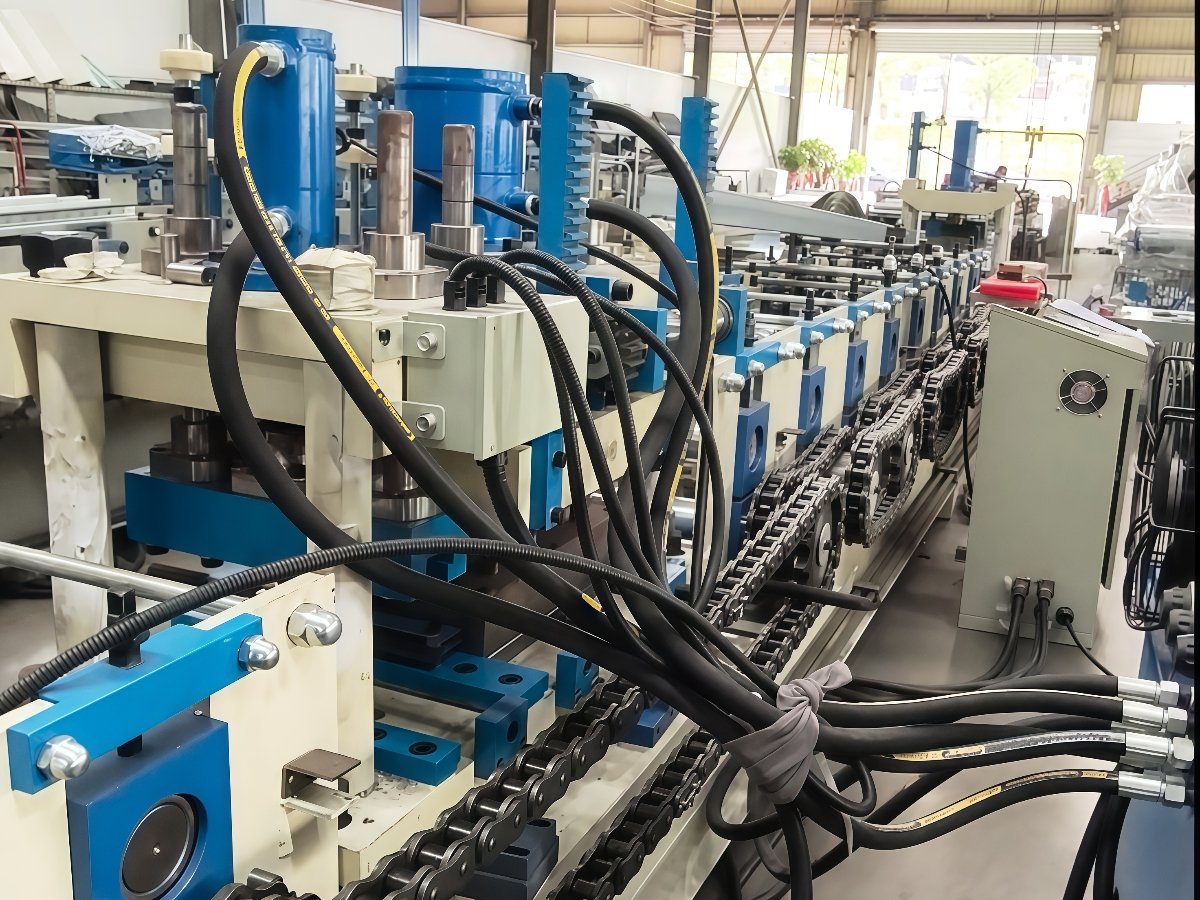

Working Flow: Decoiler —Servo Material Feeding—200T Punching Device—Feeding Guide—Forming—Shaping—Cutting

Main Tech Parameters:

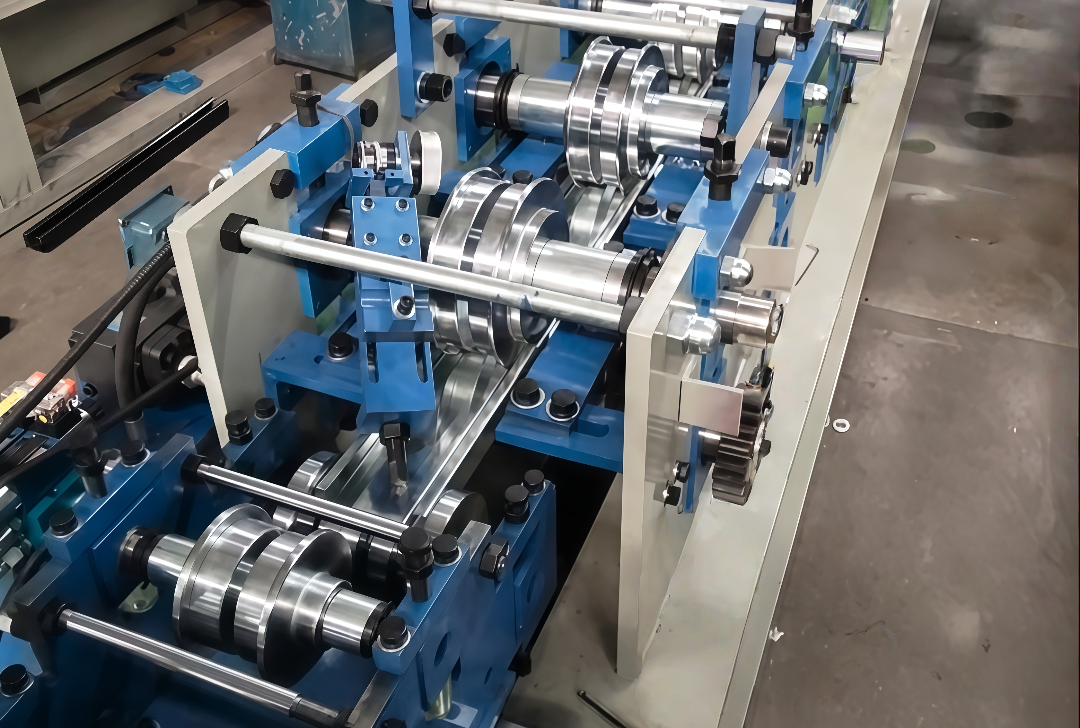

| Forming Station | 20 station for forming + 3 for shaping |

| Shaft Diameter | 75mm |

| Machine Frame | H400 frame+ 18mm Side panels |

| Rollers Material | GCR15 steel, heat treated |

| Main Power | 22KW |

| Forming Speed | 17-20M/Min |

| Hydraulic Cutting Power | 5.5KW |

| Material Feeding Power | 3KW Servo Motor |

Other Supporting Equipment

Support Beam Machine

Beam Roll Forming Machine

レビュー

レビューはまだありません。