Z Purlin Roll Forming Machine Australia

The Beenew Z purlin roll forming machine, also referred to as a galvanized steel Z-section purlin roll former, is specialized equipment designed to manufacture Z-shaped steel profiles.

説明

Z Purlin Roll Forming Machine

The Beenew Z purlin roll forming machine, also referred to as a galvanized steel Z-section purlin roll former, is specialized equipment designed to manufacture Z-shaped steel profiles.

These Z-section steel purlins exhibit exceptional bending resistance, superior linear precision, and compatibility with integrated in-line processes such as punching and cutting during production.

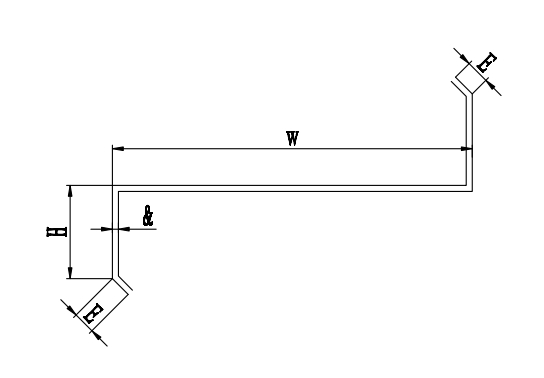

Profile drawing

Z Purlin Machine Flow Chart

Uncoiler- Pre-Shearer- Flattening & Guiding -Z Purlin Main Roll Forming Machine – Hydraulic Punching – Post Cutter -Product rack

Main Components Of The Z Purlin Machine

1.Decoiler

Type:Manual decoiler or hydraulic decoiler

Load capacity:7T

2.Flattening and Guiding System

Flattening system: Upper 3 and lower 4 rollers plus additional pressure rollers are used to level the steel coils

Guiding system:Equipped with a guiding shaft and guiding rollers, its width can be adjusted to accommodate various steel strips.

Machine shaft: 40Cr quenched and tempered

3.Main Z roll forming machine

Forming stand:21 stations

Roller material: flat wheel Gcr15 bearing steel/slant wheel Cr12 mold steel

Transmission type:chain drive+gear/sprocket drive

Mchine base:Welded using H500 plate, undergoes shot blasting and heat treatment processes

Roller material: flat wheel Gcr15 bearing steel/slant wheel Cr12 mold steel

Z purlin machine main drive: servo motor

Machine shaft: 40Cr quenched and tempered

Purlin size adjustment: continuous adjustment through PLC control and touch panel settings

Purlin Straightening Unit:Two-axial straightening units with 10 rollers, along with 4-roller axial straightening units. These are designed to guarantee that the purlin will not experience curving, bowing, sweeping, or twisting

4. Hydraulic punching

Punching unit configuration: 3 sets

Punching type: A post-punching unit and an automated punching mechanism

5. Post cutter

Type:Adopts post-cutting technology,automatically cut the material to the specified length and quantity

Cutter material:Cr12Mov mold steel wire cut and heat treated

6. Power supply & Control System

Control cabinet: 1 sett,with an ’emergency stop’ switch

Control handle: 1 set of control handle is provided

Operation platform:HMI and buttons,has an English language display

7. Product rack

Type :2 sets, 3 meters each, free roller type

Overview of other optional systems

Inkjet printing system: custom printing of company name, corporate logo, product code, etc. on purlin flanges

Pre-cutting mechanism: quick change of steel coils without affecting production flow

Flat plate pre-punching equipment: pre-punching and slotting operations

Automated stacking system: stacking of processed C- and Z-shaped purlins

Additional punching unit: supports additional installation of punching devices

Main advantages of Z purlin machine

High degree of machine automation: fully automatic purlin size adjustment

Wide range of steel and purlins: raw material types can be galvanized steel, black steel.

Universal cutter: Suitable for all C, Z and U purlin sizes

Quick change: Quick Z purlin size within 2 minutes

Through shaft design: Reduces uneven height caused by machine spindle breakage

High-strength structure: Made of cold-pressed high-strength steel plate, uniform wall thickness and high compressive strength

High precision: High plate shape accuracy, easy adjustment of length offset and purlin punch position

レビュー

レビューはまだありません。