Door Frame Making Machine

説明

Door Frame Roll Forming Machine

Door Frame Making Machine

The Beenew Door Frame Roll Forming Machine combines a decoiler, feeding/leveling unit, roll forming system, hydraulic post-cutting, run-out table, hydraulic power station, and PLC control.

Its extended production line ensures high-quality profiles with minimal time/labor, boosting efficiency for modern manufacturing needs. Designed for simplicity, it delivers stable operation and precision throughout production.

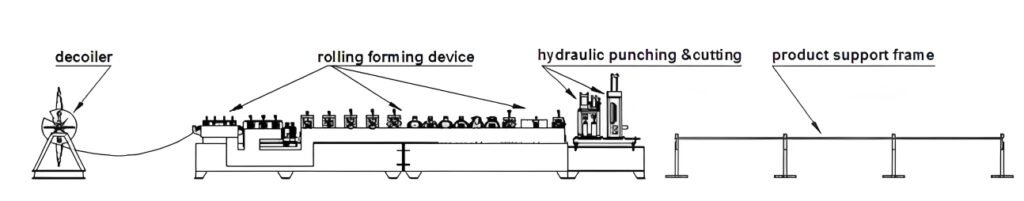

Flow chart

Decoiler → Sheet guiding → Hydraulic punching system → Roll forming line → Post-Cutting → Product rack

Material

Profile Size Adjustment Type: Roller Sleeve Replacement System

Compatible Coil Thickness: 1.5 mm

Applicable Raw Materials: Galvanized steel sheet; Galvanized color-coated sheet

Raw Material Yield Strength: Q235-grade, 235 MPa

Main Components of Door Frame Making Machine

1.Decoiler

Capacity: 5 tons

Inner diameter: 600mm

2. Pre-Punching System

5 cylinders punching device,1 set

Punching dies,10 sets

Punch and die materials: Cr12 steel with precision finishing and heat treatment

3.Roll Forming Machine

Main Frame Construction: Individually welded frame components with exterior walls screw-connected after rotary shot blasting surface treatment.

Roller Material: High-grade No. 45 forged steel, processed via digitally controlled machining for dimensional accuracy.

Roller Shaft Precision: Precision-ground twice using specialized grinding equipment to guarantee final product dimensional consistency.

Surface Treatment: Hard chrome plating (0.05 mm thickness) applied post-machining via precision tooling, ensuring extended durability of forming rollers.

4.Hydraulic Post Cutting Unit

Operation Mode: Stop-cut mechanism with post-cutting execution

Tooling Configuration: Dual-tool setup – dedicated blade sets per product specification

Blade Material: Cr12 tool steel, quenched and hardened to HRC 60-62.

Frame Design: Welded structural frame for enhanced rigidity and vibration resistance

Cutting Precision:Heat-treated cutting frame to minimize product deformation

Cutting length tolerance: ±1 mm.

Power Source: Hydraulically driven via dedicated hydraulic power station

Automation:PLC-programmed length control with rotary encoder for real-time measurement

Automated stop-cut operation: Triggers cutting upon reaching preset length, resumes continuous operation post-cut

5.Hydraulic Power Unit

Function: Delivers hydraulic power to operate the cutting mechanism

Power Output: 7.5 kW electric motor (standard: 380V/50Hz or as per regional requirements)

6. Product Rack

Used to Collect the final product,convenient to be stacked

Support length: 1 set(3 meters)

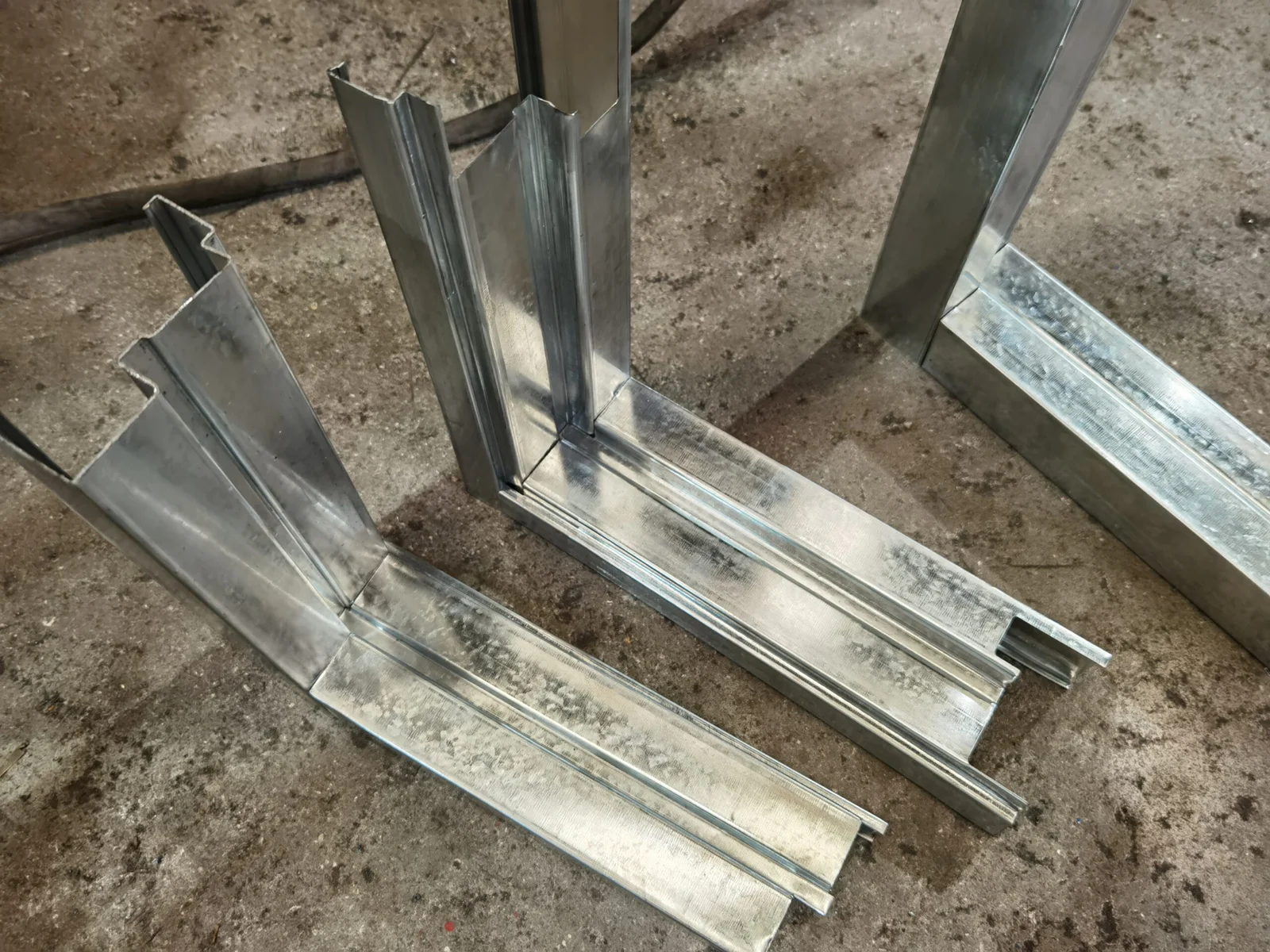

7. Product Sample

FAQ

Q: Are you a trading company or a manufacturer?

A: We are a direct manufacturer with a dedicated production team and export-focused service expertise in cold roll forming machinery.

Q: Can the machine produce only one panel profile?

A: No. Our machines are engineered for multi-profile versatility, supporting wider and dual-layer production capabilities. A single unit can produce 3+ distinct panel profiles with tooling adjustments.

Q: What is the typical lead time for machine production?

A: Standard lead time is 20–45 business days. For urgent orders, we prioritize production to expedite delivery without compromising quality.

Q: How is quality control ensured during manufacturing?

A: Our rigorous QC protocol includes raw material inspection,precision machining of rolls and critical components.

Assembly verification,surface and shaft integrity testing,pre-shipment operational trials and packaging checks.

Q: What if the machine malfunctions?

A:24-month warranty,Free replacement of irreparable parts (customer covers shipping fees).

Post-warranty support: Lifetime technical assistance and negotiated repair solutions.

Q: What differentiates you from competitors?

A: Our strengths include customer-centric service with tailored engineering solutions.

Low-maintenance, user-friendly designs for quick installation and operation.

Value-added guidance to optimize your ROI and product performance.

Q: Can we partner as your international agent?

A: Absolutely! We actively seek collaborations with distributors or agents to sale our roll forming machine.

レビュー

レビューはまだありません。