Similar Posts

Which are the well-known roll forming machine manufacturers?

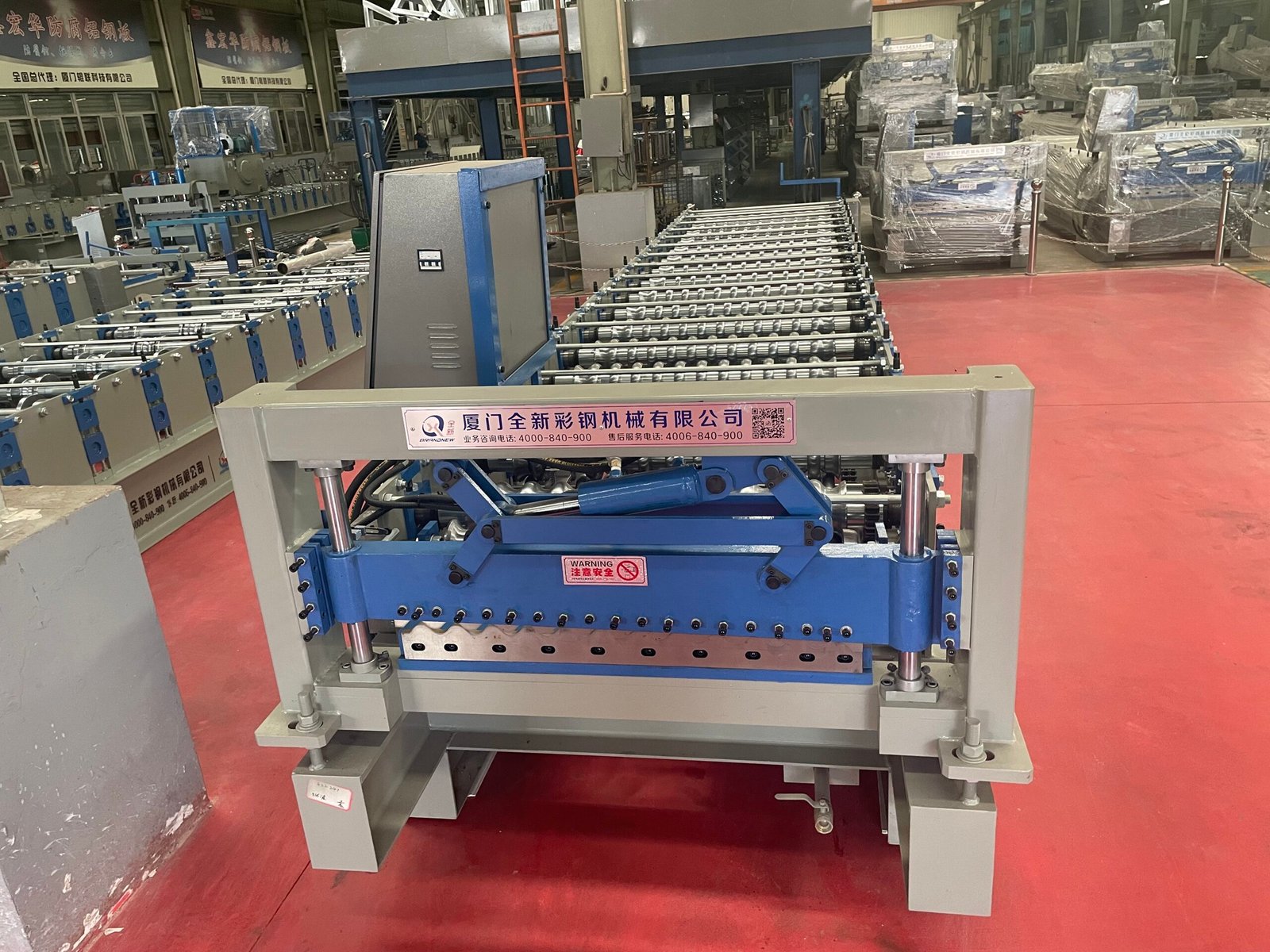

Home / BEENEW MACHINERY is a leading roll forming machine manufacturer and forming solution provider. We can manufacture kinds of forming machines in the construction industry, solar photovoltaic industry, and transportation industry. With more than 28 years of experience in forming machine manufacturing, we provide high-quality forming machines and innovative roll forming solutions to more than 50…

What are the common aliases for a roll forming machine?

Home / 1.What are the common aliases for a roll forming machine? Roll forming machines, pivotal to modern manufacturing, are known by various names across industries and regions. These aliases often reflect the machine’s functionality, design nuances, or specific applications. 1.Roll Forming Machine This is the most widely recognized term, emphasizing the machine’s core mechanism:…

Polyurethane Sandwich Panel Production Line: Leading the Way in Energy – Efficient Building Applications

Home / Polyurethane Sandwich Panel Production Line plays a crucial role in energy – efficient building applications:Product Features Enabling Energy EfficiencyThe polyurethane sandwich panels produced by the production line have excellent insulation properties. They are made with a core material that can effectively prevent heat transfer, which helps maintain a stable indoor temperature. For example,…

What is a purlin?

Home / A purlin, also historically known as purline, purloyne, purling, or perling, serves as a critical structural component in roofs. It is a longitudinal, horizontal member that provides structural support, often positioned beneath the roof. Supported by either the building’s rafters or walls, purlins are horizontal beams or bars frequently utilized in metal buildings….

What Makes Up a Roll Forming Machine?

Home / 1.What main components does a roll forming machine consist of? Roll forming machines are the workhorses of manufacturing. They take metal coils and shape them into all sorts of profiles—like corrugated roofing sheets, wall panels, or structural parts. Here’s a breakdown of the key parts that make these machines tick: The Uncoiler Think…

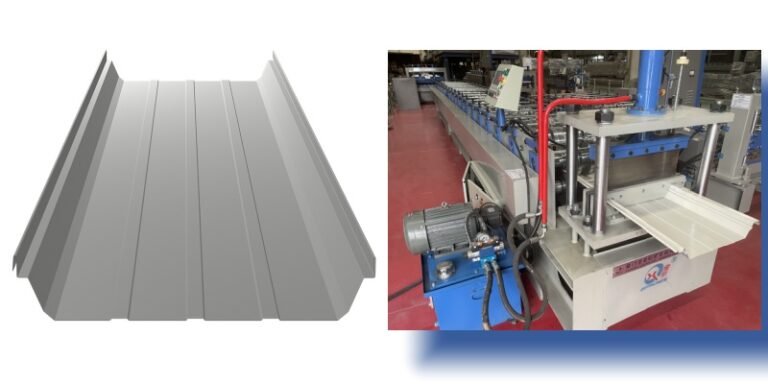

Which type of standing seam roofing is suitable for your construction?

Home / Standing seam roofing roll forming machine – Which standing seam roofing is right for your building? 2 min read The outstanding features of standing seam roofing you should know – 2 min read What is standing seam metal roof? Do you know what standing seam roof panels are? If you don’t know, read…