Trimdek Sheet Roll Forming Machine Australia

Australia Trimdek Sheet Roll Forming Machine – Crafted by the Chinese roll – forming machine manufacturer, Beenew Machinery, these Lysaght Trimdek Sheet Roll Forming Machines meet Australian safety standards.

Descripción

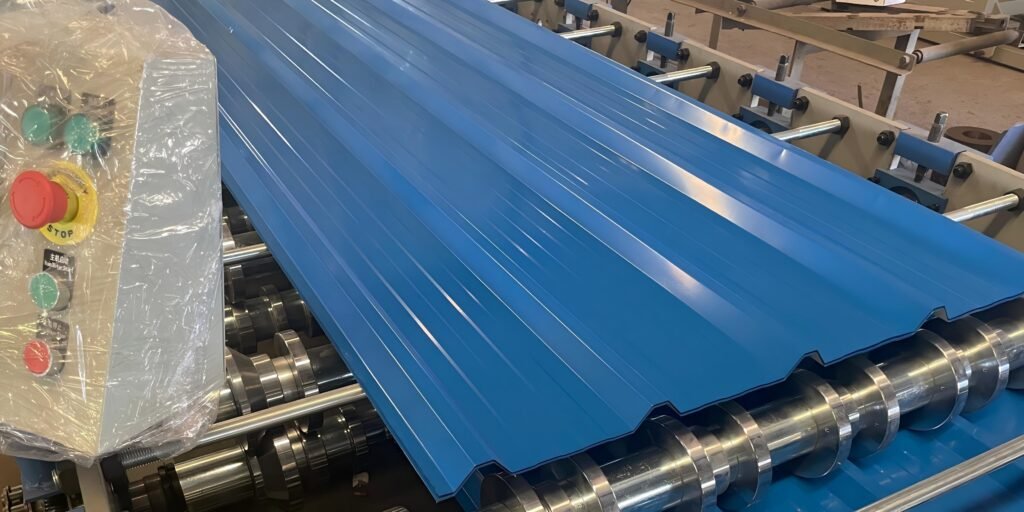

Trimdek Sheet Roll Forming Machine Australia

Australia Trimdek Sheet Roll Forming Machine – Crafted by the Chinese roll – forming machine manufacturer, Beenew Machinery, these Lysaght Trimdek Sheet Roll Forming Machines meet Australian safety standards.

The Trimdek roofing profile stands out as an extremely good long – spanning cladding choice. It allows for wide support spacing, and it’s a highly versatile profile that combines strength with light weight.

The Trimdek sheet presents a highly cost – effective and rapid – installation solution boasting a 760mm sheet coverage. Its 28mm rib height and a specially engineered capillary groove guarantee watertight performance even at a two – degree roof pitch.

Concerning the sheet cover, there’s a notable difference between the cover width, which measures 762mm, and the actual sheet width, which is 820mm.

As for the steel thickness, the standard thickness of BlueScope Lysaght Steel sheets ranges from.42 to 0.48BMT.

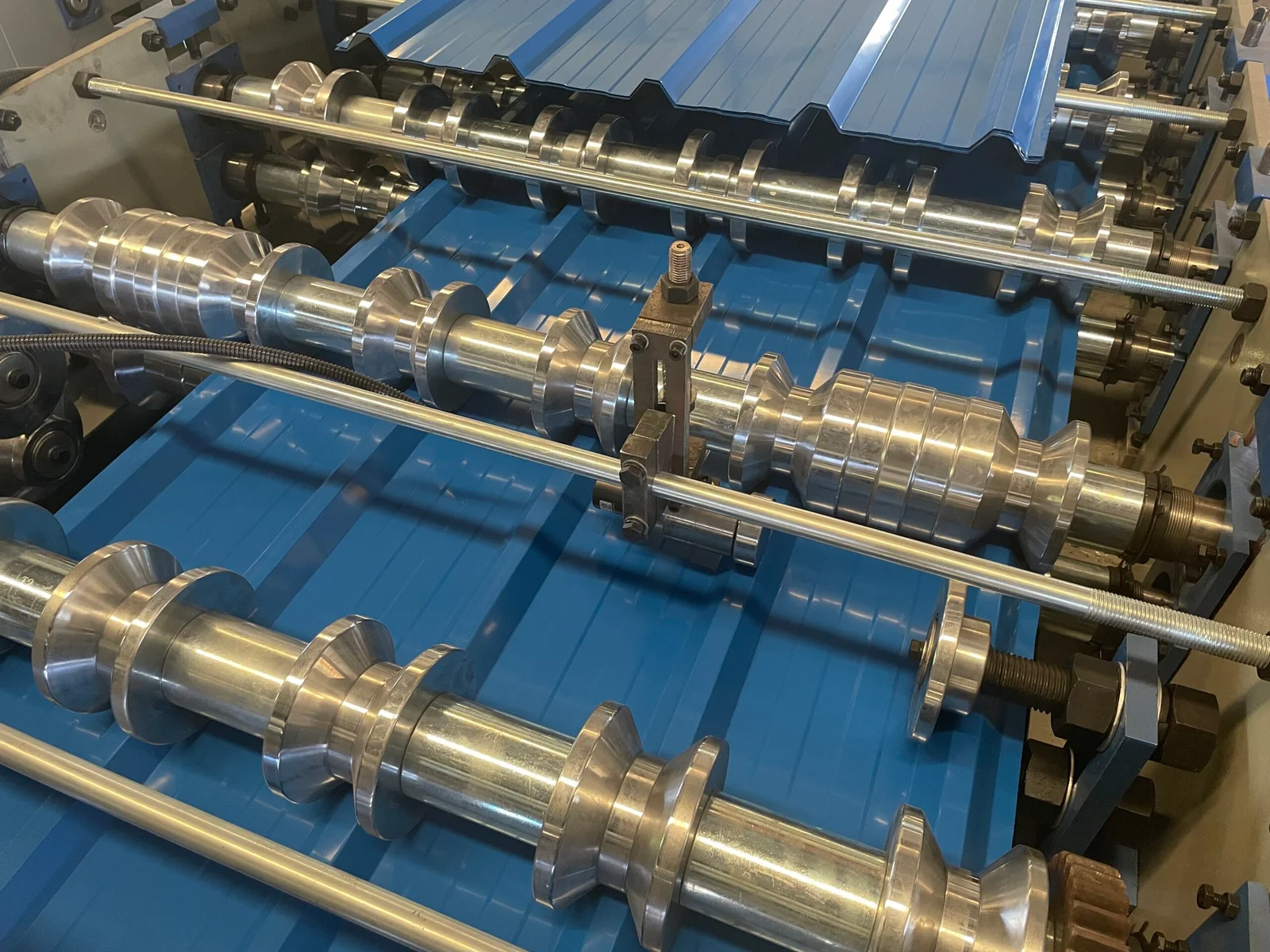

In addition, some of the popular profiles in Australia include corrugated roofing, kliplop 700, and spandek. Australians typically prefer using hard materials with a yield strength of 500mpa to enhance the hardness of the final roofing products.

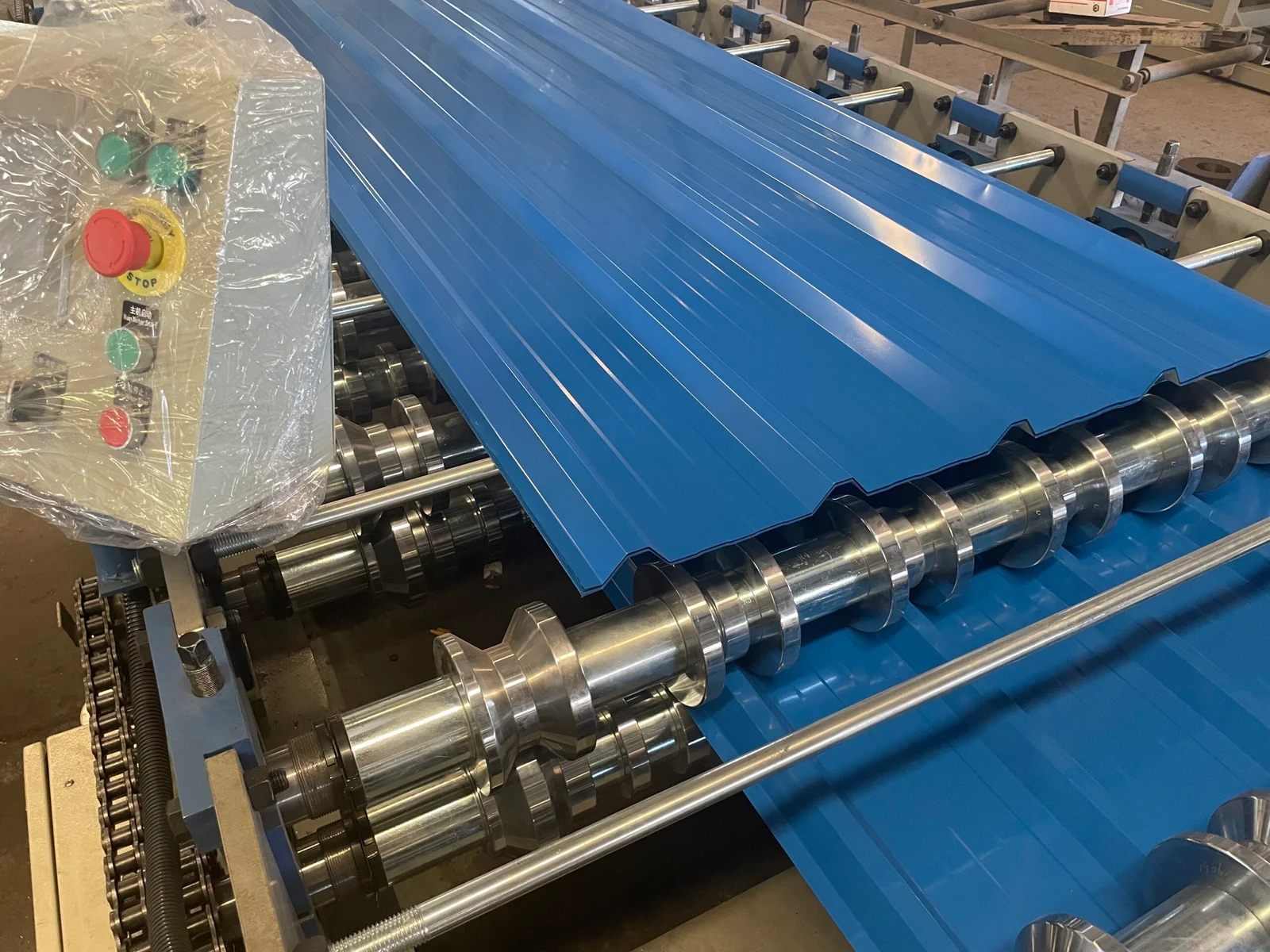

Nonetheless, hard materials exhibit brittleness and are susceptible to fracture during the forming procedure.Fortunately, Beenew Machinery factory has extensive years of experience in designing and manufacturing such roll – forming machines.

We have successfully supplied roofing sheet machines, gutter machines, fascia machines, and CZ purlin machines to Australia.

APPLICATION

Beenew Machinery factory is committed to designing roofing machines tailored to your specific roofing profile or design. Pre – engineered metal buildings offer the following advantages:

- Durability: They are built to last, with a long – lasting performance.

- Resilience: Capable of withstanding severe environmental conditions.

- Cost – effectiveness: Feature a low overall cost.

- Low Investment and Maintenance: Require a low initial investment and have minimal maintenance costs.

- Environmental Friendliness: These buildings are eco – friendly.

- Recyclability: All the materials used can be recycled.

- Design Flexibility: Provide a high degree of flexibility in design.

- Relocability: Can be relocated with relative ease.

- Reduced Installation Time: Significantly cut down the installation time.

These machines are user – friendly, operating automatically under the control of a PLC controller. The working process includes unwinding the coil from the decoiler, forming the sheets, cutting them to the desired length, and then allowing the finished products to run out.

FAQ

Q: Are you a trading company or a manufacturer?

A: We are a direct manufacturer with a dedicated production team and export-focused service expertise in cold roll forming machinery.

Q: Can the machine produce only one panel profile?

A: No. Our machines are engineered for multi-profile versatility, supporting wider and dual-layer production capabilities. A single unit can produce 3+ distinct panel profiles with tooling adjustments.

Q: What is the typical lead time for machine production?

A: Standard lead time is 20–45 business days. For urgent orders, we prioritize production to expedite delivery without compromising quality.

Q: How is quality control ensured during manufacturing?

A: Our rigorous QC protocol includes raw material inspection,precision machining of rolls and critical components.

Assembly verification,surface and shaft integrity testing,pre-shipment operational trials and packaging checks.

Q: What if the machine malfunctions?

A:24-month warranty,Free replacement of irreparable parts (customer covers shipping fees).

Post-warranty support: Lifetime technical assistance and negotiated repair solutions.

Q: What differentiates you from competitors?

A: Our strengths include customer-centric service with tailored engineering solutions.

Low-maintenance, user-friendly designs for quick installation and operation.

Value-added guidance to optimize your ROI and product performance.

Q: Can we partner as your international agent?

A: Absolutely! We actively seek collaborations with distributors or agents to sale our roll forming machine.

Valoraciones

No hay valoraciones aún.