Concrete-free Floor Deck Roll Forming Machine

Concrete-free metal floor decking machine is to produce decking panels which does not require concrete pouring after on-site installation, which greatly improves construction efficiency.

Descripción

Concrete-free Floor Deck Roll Forming Machine is used to produce steel decking strips. These strips are widely used in many places. The primary function is used as load bearing and dividing components between floors. Some are used as platform panels, such as equipment platforms, maintenance walkways, mezzanine platforms, scaffolding planks, steel truss floor decks.

The main types of machines we produce in this category include the standard version, the fully automatic model change version, and the tracking punching-and-cutting version. Customers can choose the one that best suits their needs based on their budget, production requirements, and specific project demands.

1. Standard Version

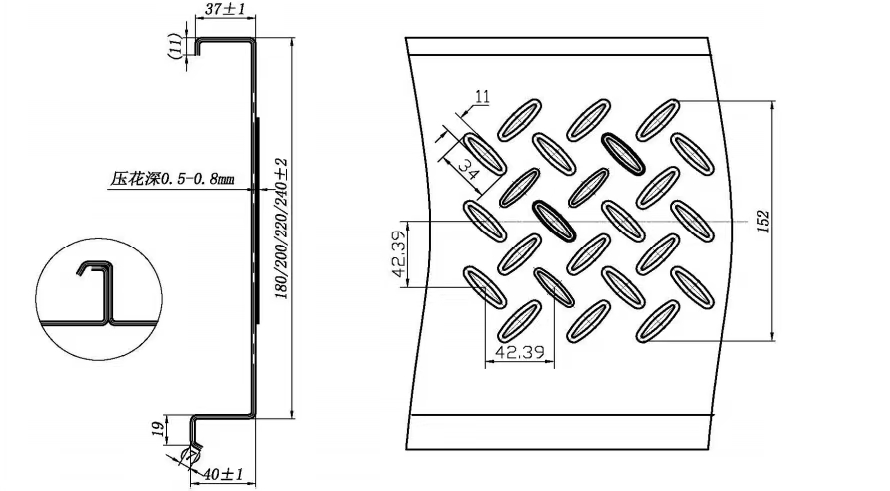

This version is designed to produce metal floor decking panels with thickness 2.0-3.0mm of normal tension. The panels are with a fixed height of 40mm and a bottom width of 180/200/220/240mm. The bottom sizes are changed by manually replacing the spacer rings.

This type is very user-friendly for customers who require diverse sizes but need to control costs.

Profile Drawing:

Main Parameters:

Applicable raw materials: 2.0-3.0mm Q235 GI Coil

Size-changing Type: Manual

Shafts Diameter:75/90mm

Machine Frame:H400

Forming Station: 16 station for forming+3 stations for shaping

Rollers: GCR15, heat treated, hard chrome coated

Speed: 15M/min

Main Motor:18.5KW

Hydraulic Motor:5.5KW

Cutting:With hydraulic pre-cut and post-cutter, which made from CR12,heat treated

Video:

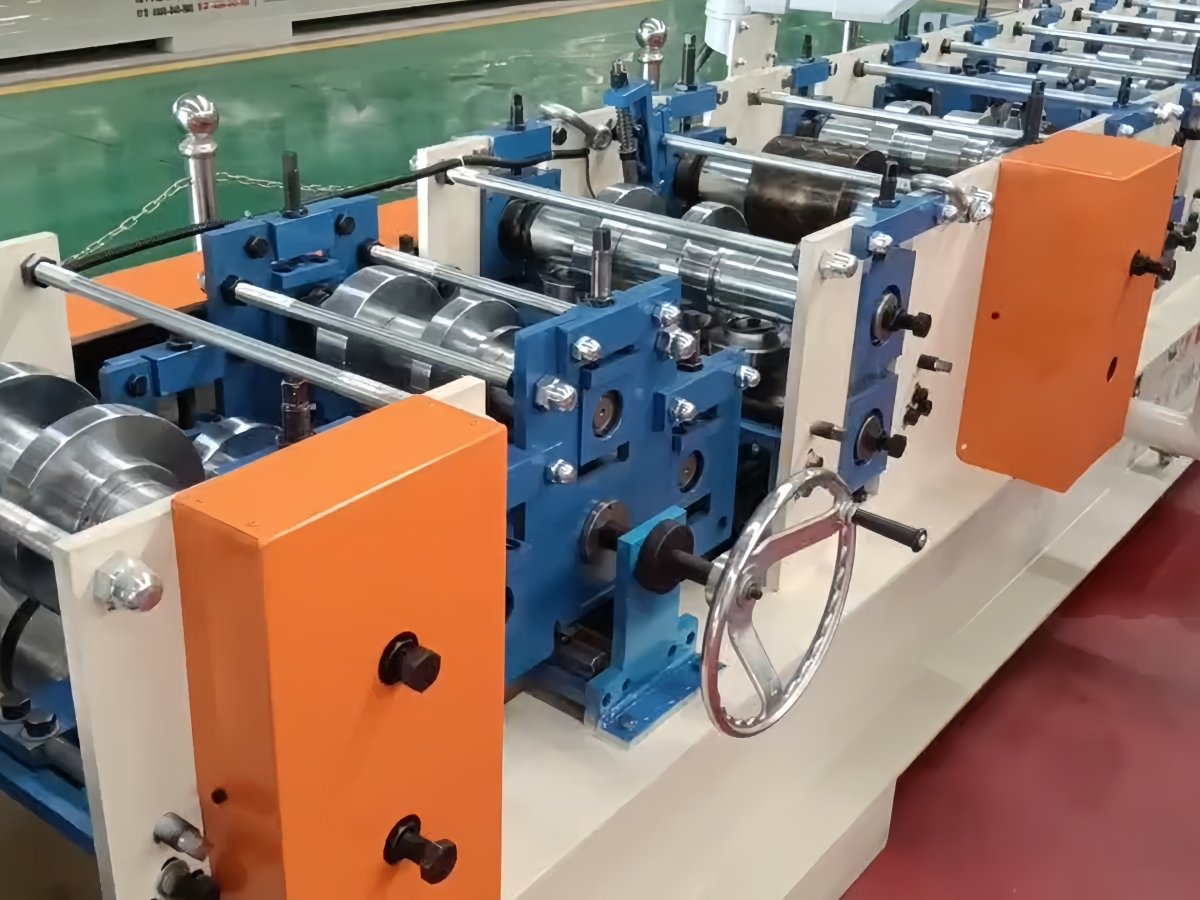

2. Automatic Model Changing Version

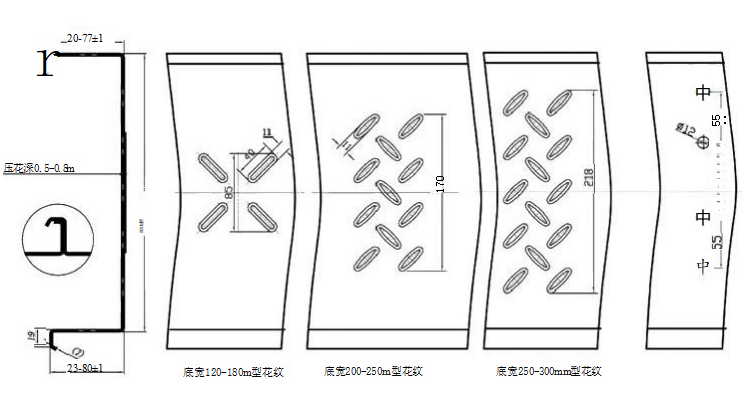

This is a fully automatic version of floor decking machine. It can reach completely automatic computer-controlled adjustment of both the height and width of floor deck strips. Switching between sizes is done with one-click operation, followed by minor manual fine-tuning.

It supports adjustable web heights from 20 to 80 mm and flange widths from 120 to 300 mm, and can process sheet metal thicknesses of 1.0–3.0 mm.

This is a high-spec model, with reinforced shafts, thicker frame side plates, more rolling stations, higher-grade roller materials, and more powerful motors. It uses servo motors for faster and more precise speed control.

Because the flange size is adjustable, the machine comes with three sets of embossing rollers. This allows different embossing patterns to be applied across different width ranges. Users can simply select the corresponding embossing roller set according to the desired finished width—no need to disassemble the top or bottom rollers.

Profile Drawing:

Main Parameters:

Applicable raw materials: 1.0-3.0mm Q235 to 355 GI Coil

Size-changing Type: Full Automatic

Shafts Diameter:90/75mm

Machine Frame:H450

Forming Station: 18 station for forming+3 stations for shaping+3 for embossing

Rollers: CR12, heat treated

Speed: 28-30M/min

Main Motor:30KW Servo Motor

Hydraulic Motor:11KW with cooling device

Cutting:With hydraulic pre-cut and post-cutter, which made from CR12,heat treated

Video:

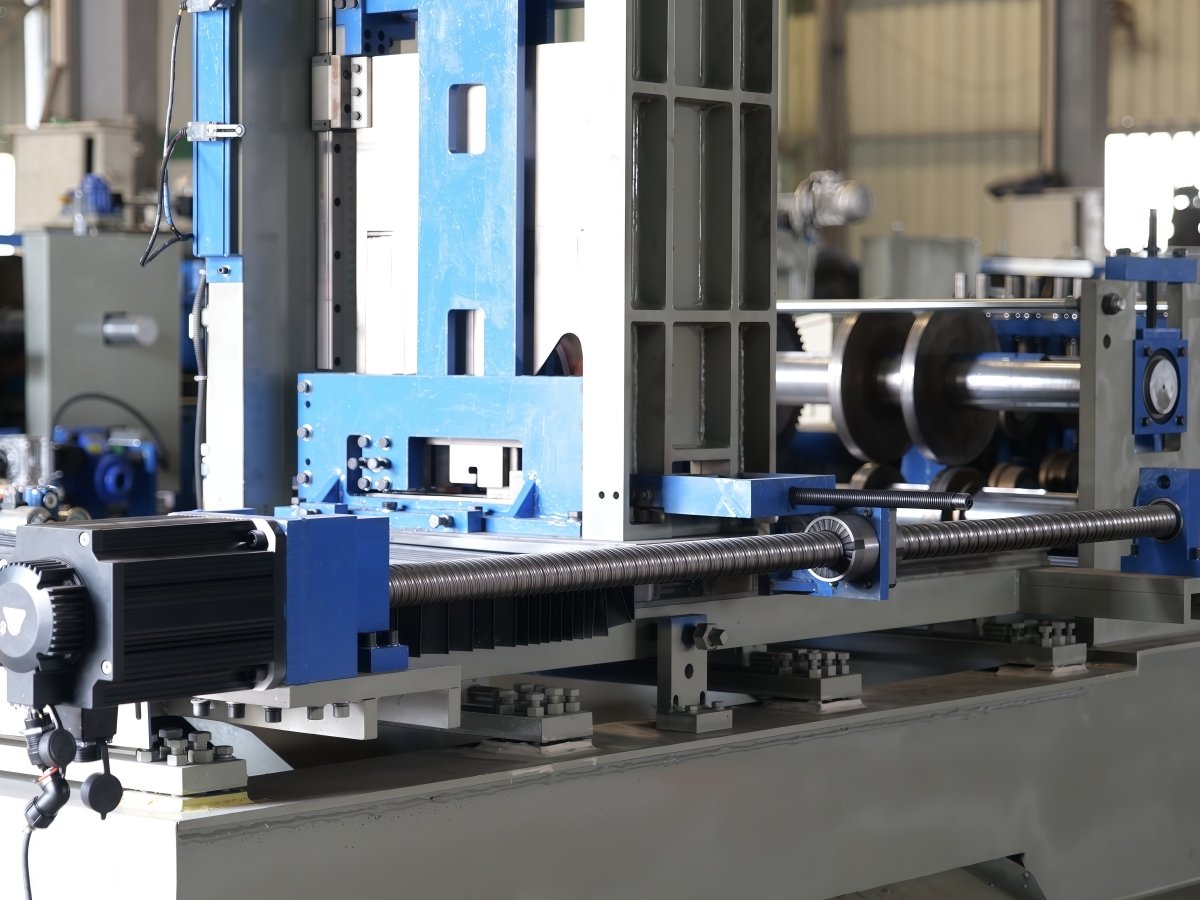

3. Tracking Punching-and-Cutting Version

This metal deck machine is an upgraded model based on the fully automatic version, and most of its specifications are the same as the fully automatic model.

The main difference is that it uses a «following punch and cut» method, which means punching and shearing without stopping the machine. This significantly speeds up production, making it the preferred choice for customers with urgent projects or high production demands.

Of course, if you don’t want the «following punch and cut» mode, you can still choose to stop the machine for shearing – the option is flexible.

In addition, the machine is equipped with an oil/soap lubrication system to lubricate and cool the rollers.

Video:

Valoraciones

No hay valoraciones aún.