Standing Seam Roofing Machine

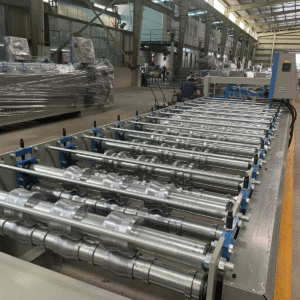

Portable standing seam metal roof machine can be brought directly to the construction site. They allow for panels to be formed on-demand to the exact length needed, minimizing waste and handling.

Descripción

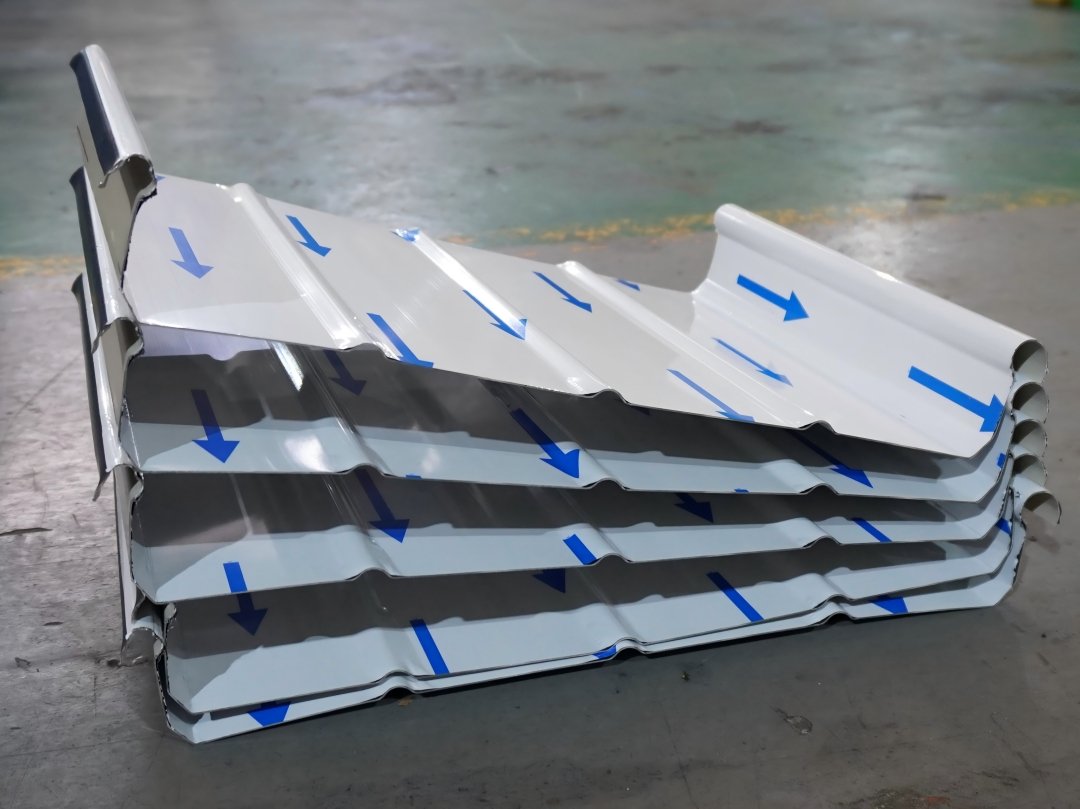

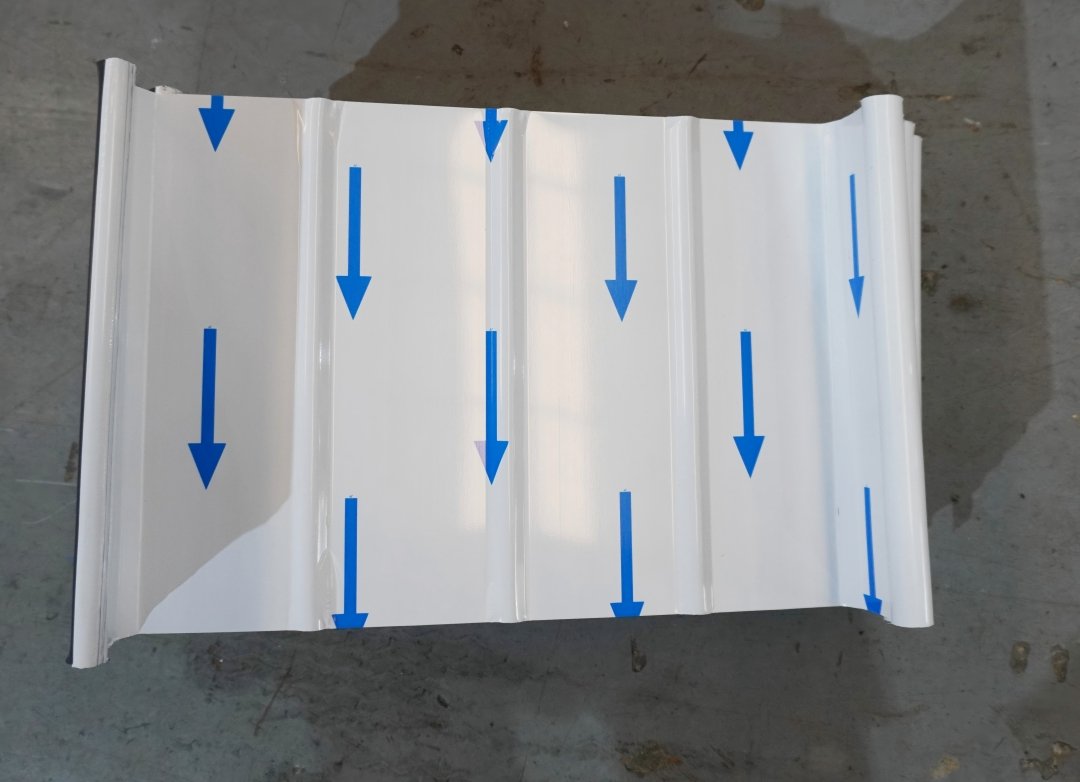

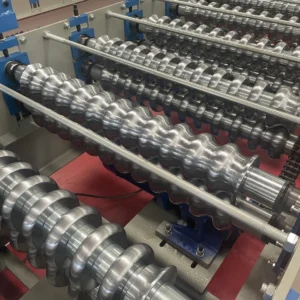

The standing seam roof panel forming machine is an automated machine that continuously processes rolled metal sheets (such as aluminum-magnesium-manganese sheet and galvanized steel) into «standing seam roof panels» with specific cross-sectional shapes on-site.

It enables on-site, instant production of roof panels, with customization lengths to meet roofing requirements, minimizing overlap and waste. High forming precision ensures perfect interlocking of the male and female ribs of each panel, resulting in an excellent waterproof seal.

Due to its excellent waterproofing, wind resistance, aesthetics, and ability to accommodate large spans, the standing seam system is widely used in large-scale public buildings and industrial facilities with demanding roofing requirements. Such as stadiums, airport terminals, convention and exhibition centers, theaters and concert halls, logistics warehouses, and factory workshops.

Main Parameters:

Material Thickness:0.7-1.2mm

Effective Width:400/425mm

Feeding Width:575/600mm

Forming Station:13 stations

Main Motor:7.5KW

On-site Construction Pictures

Valoraciones

No hay valoraciones aún.