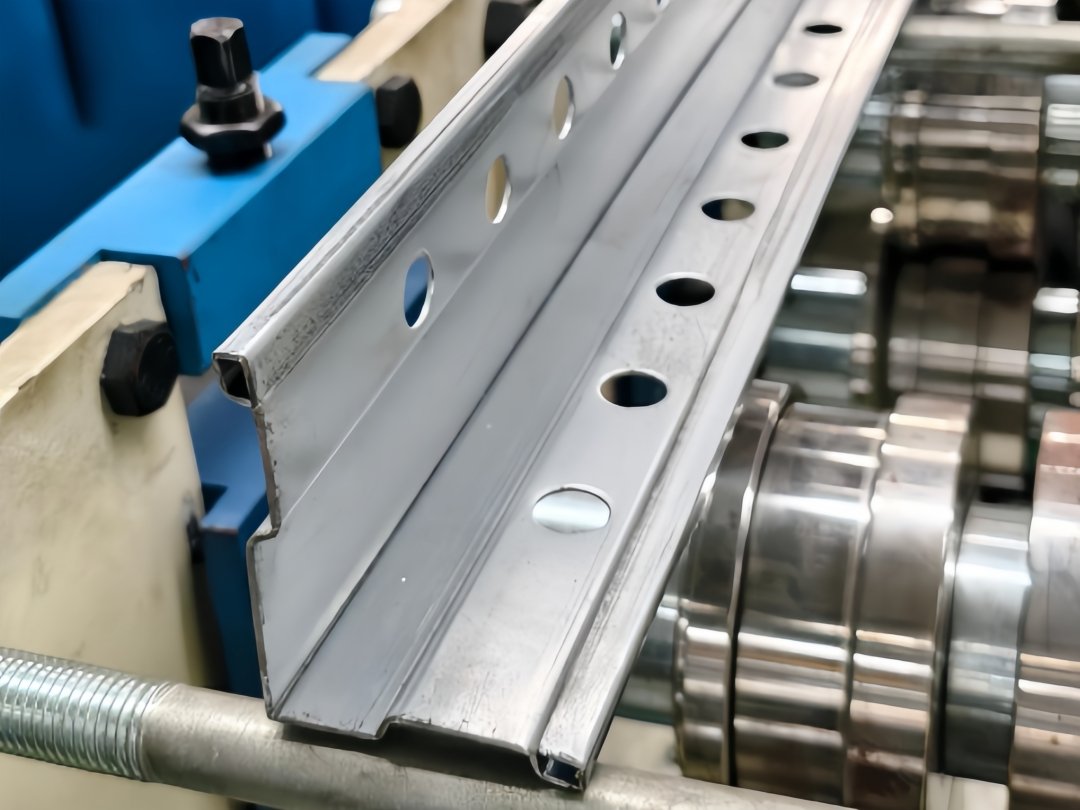

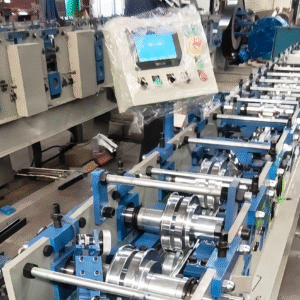

L Angle Profile Roll Forming Machine

Angle profile is not the main load-bearing part in warehouse racking systems.

It is not used as uprights or beams, but as an important auxiliary, reinforcing, and connecting role in racking systems

Descripción

L Angle Profile Roll Forming Machine

Main Functions of L Angle Profile Roll Forming Machine

1.As a backstay (horizontal tie rod and diagonal tie rod)

In racking system, as a backstay, it effectively resists lateral forces along the aisle direction (row direction), such as forklift impacts, earthquakes, or thrust caused by uneven cargo placement, preventing racking from tipping over or deforming.

2. As a Barrier (Shelf Support or Cargo Stopper)

On shelving or light-duty racking, smaller L-shaped steel beams can serve as support beams for the shelves. Alternatively, at the rear of pallet racking, they can act as barriers to prevent pallets from slipping off the back of the rack. It provides simple support and blocking functions; simple structure and low cost.

3. As a Connector or Reinforcing Rib

L-shaped steel beams serve as connecting plates or reinforcing ribs to strengthen specific joints (e.g., reinforcing edges when joining components). In racking systems, they act as key «stabilizers» and «assistants»—not the main vertical load-bearing «skeleton,» but «ligaments» that maintain overall stability and prevent instability.

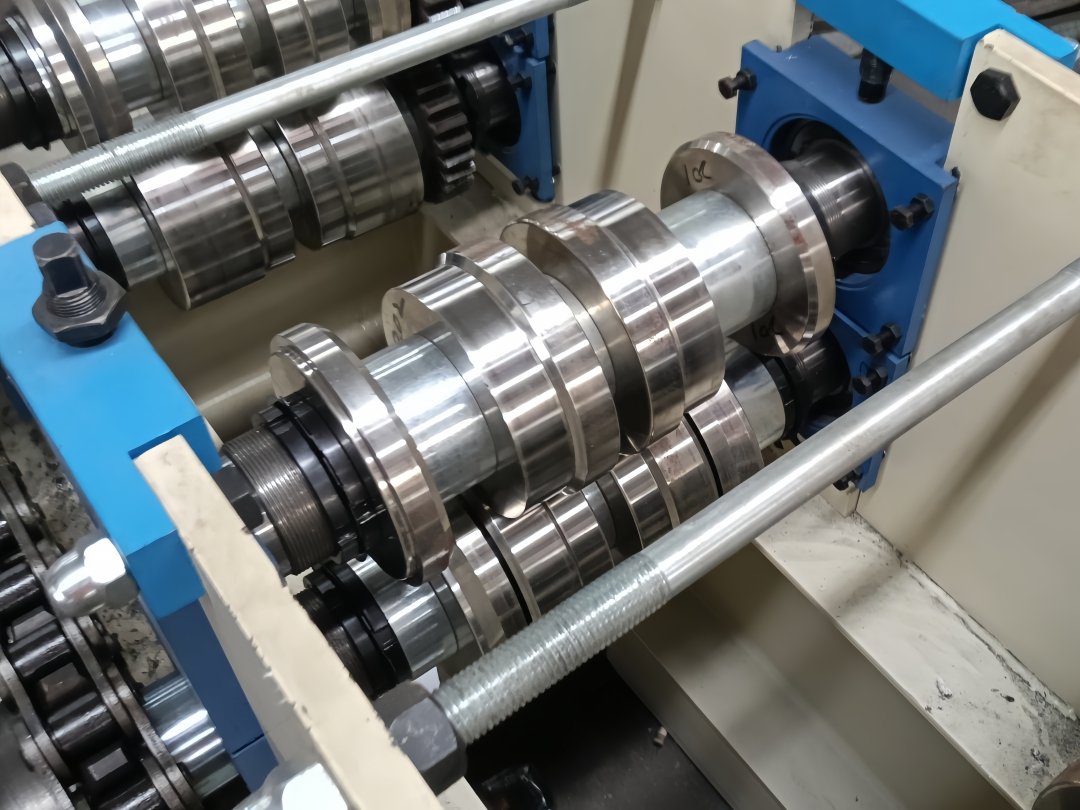

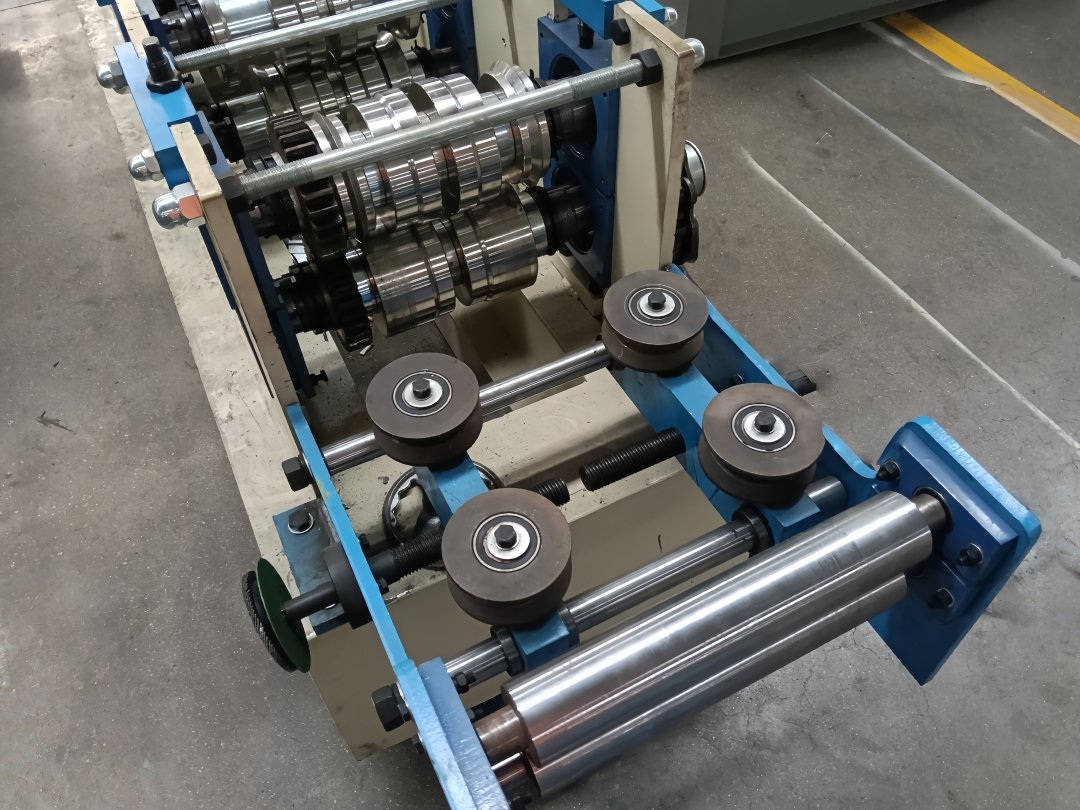

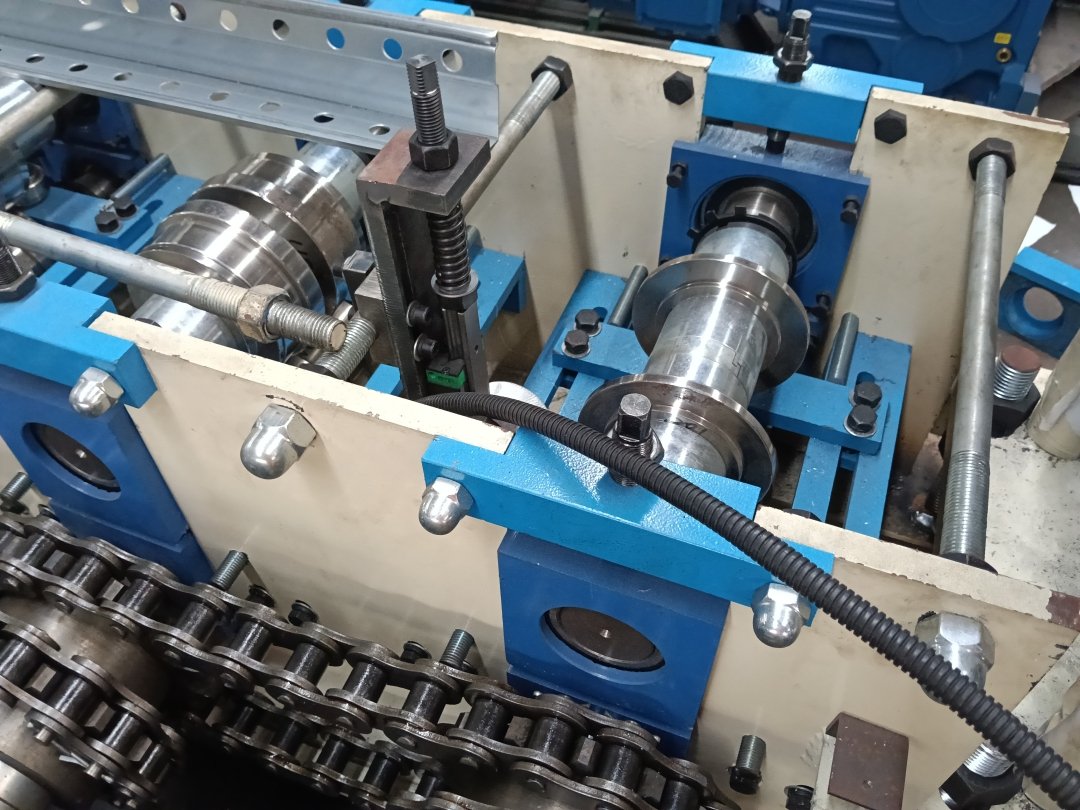

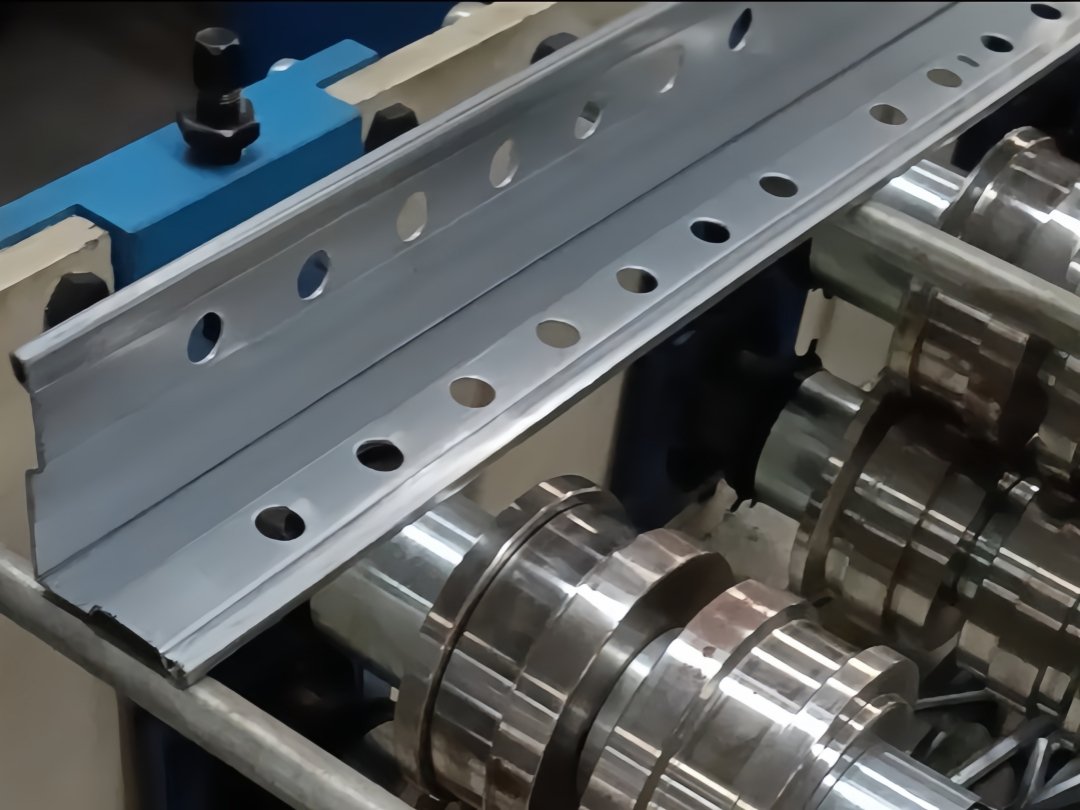

Common Production Methods of L-Shaped Steel

The production method of L-shaped steel mainly depends on its dimensions (side length and thickness), material, production volume, and required precision. The most frequently used way is cold roll forming. This is the most efficient and economical way. Metal coils (usually low-carbon steel cold-rolled coils) are passed through a series of carefully designed rolls, gradually bending them into a 90-degree angle steel shape, and finally cut to a fixed length. This kind of method are nearly of no waste and can easily produce products of any length.

Valoraciones

No hay valoraciones aún.