Rolling Shutter Machine

High quality and reasonable price, Beenew roll forming machine provide guarantee for your steel rolling shutter door business.

Descripción

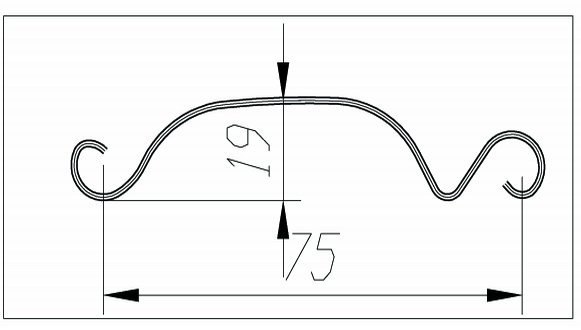

Profile Drawing

Main Parameters

| Item | Parameters |

| Material Thickness | 0.8-1.2mm |

| Driving Motor | 4KW |

| Forming Station | 14 stations |

| Roller Material | 45# steel, Surface hard chrome plating |

| Shaft Diameter | 75mm |

| Hydraulic Station Power | 2.2kw |

| Cutting Length Precision | ±2mm |

| Control System | PLC |

| Forming Speed | 12-15m/min |

1. What is a rollingshutter machine used for?

It is used to roll-form metal coils (such as steel plates and aluminum alloys) into roller shutter door panels.

2. What is its production efficiency?

High-speed models can produce 10-30 meters of door panels per minute. This machine can produce automatically which reduce labor cost a lot.

3. What types of roller shutter doors can it produce?

It can produce various kinds of door panel such as ordinary roller shutter doors, fireproof roller shutter doors, garage doors, and industrial doors.

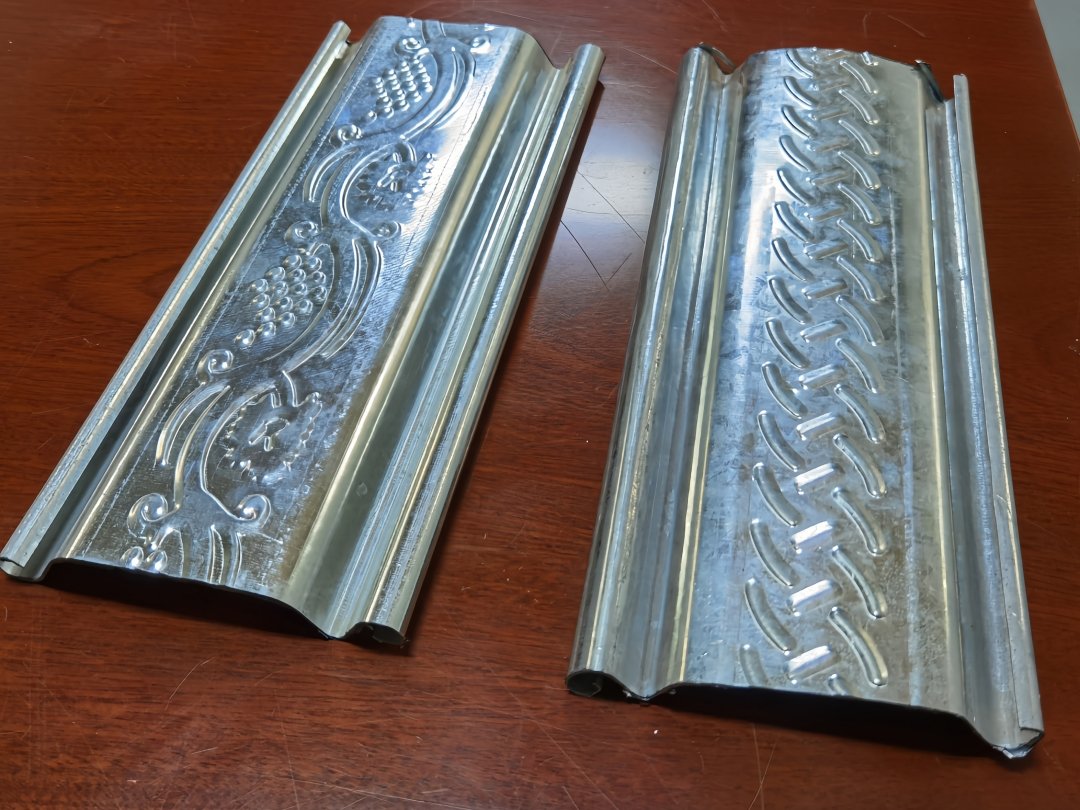

4. Can door panels of different sizes or patterns be customized?

Yes, we can do customized design and manufacture. Normally one size for one machine. If want to save space, we can do a double layer machine. And we can also do surface embossing pattern as client’s requirement.

5. How safe is the equipment?

It comes standard with emergency braking, protective covers, and an electrical safety system, meeting industrial production safety standards.

6. Are maintenance costs high?

Regular maintenance costs are low. The main wear parts are the rolls and hydraulic components, which are highly durable.

Valoraciones

No hay valoraciones aún.