Decoiler Machine

Decoiler Machine

Decoiler Machine

The decoiler machine is a piece of equipment in metal processing lines. Its primary roles include supporting and securing metal coils, controlling the speed and tension of material uncoiling, and aiding in material guiding and straightening.

Core Functions of Decoiler Machine

The decoiler machine is a piece of equipment in metal processing lines. Its primary roles include supporting and securing metal coils, controlling the speed and tension of material uncoiling, and aiding in material guiding and straightening.

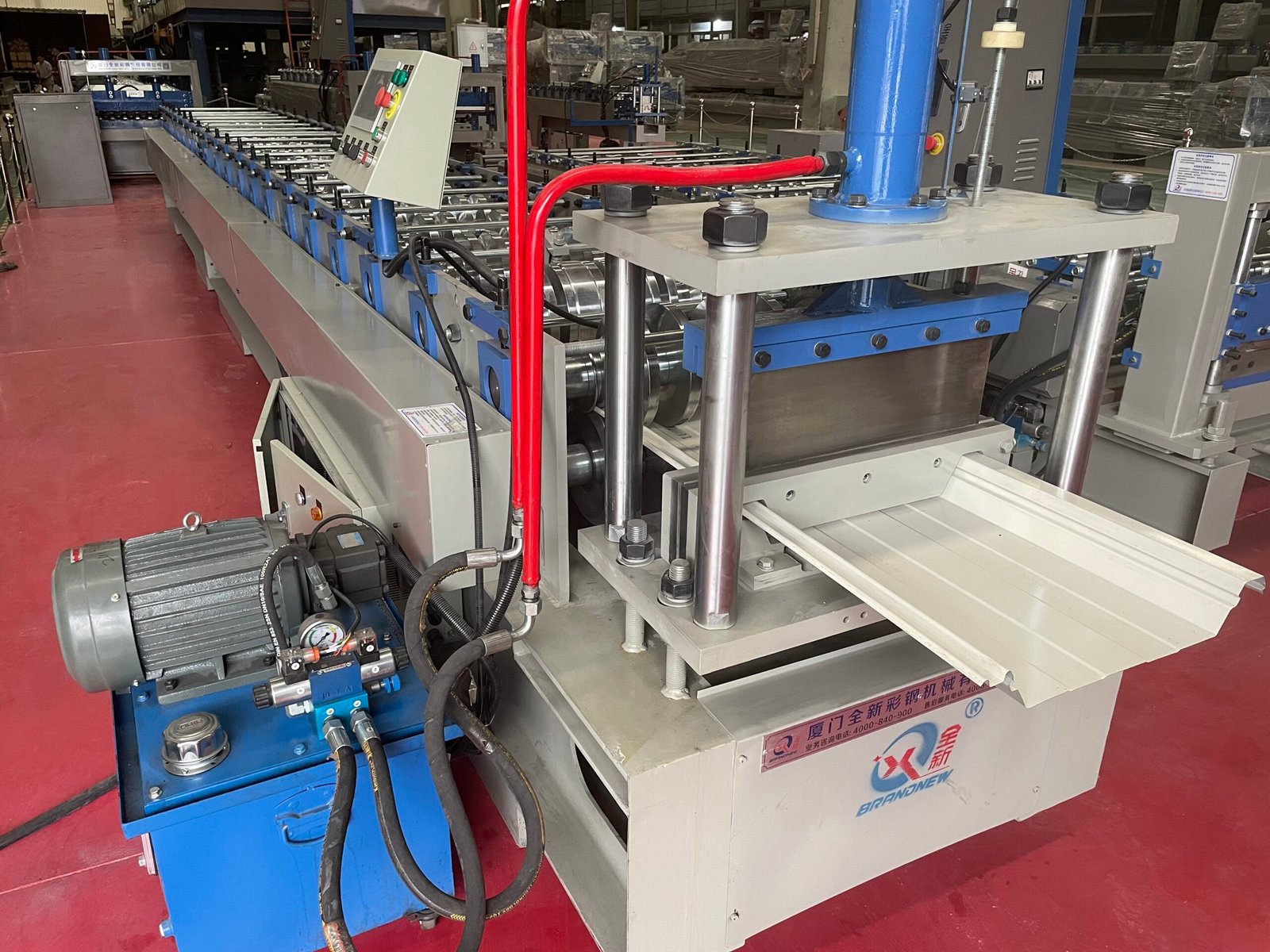

Role in Production

In metal processing operations, the decoiler acts as the front-end hub for material handling. It ensures a steady, efficient flow of materials, boosts material utilization and processing accuracy, cuts down on labor costs and operational risks, and adapts to a wide range of production needs.

Types of Decoiler Machine

Classified by driving method and function, the decoiler machine can be divided into manual decoiler, hydraulic decoiler and hydraulic decoiler with a loading trolley.

▶Manual Decoiler

No power drive, adjust the expand and contract of the decoiler by hand wheel. Because of its simple structure, it also with low cost. The appropriate load capacity and feeding width can be selected according to the supporting forming machine. The common load capacity can be 1 ton to 7 tons, and the material width can range from 300mm to 1500 mm.

Manual decoiler for purlin machine

Manual decoiler for roofing machine

▶Hydraulic Decoiler

Driven by a hydraulic system to expand/contract the reel and unwind, it has extremely strong load-bearing capacity (up to dozens of tons) and high tension control precision. The common load capacity can be 7 to 10 tons, or even 15 tons for special made. And the material width can range from 1000mm to 1600 mm.

Hydraulic decoiler for purlin machine

Hydraulic decoiler for roofing machine

▶Hydraulic Decoiler with a Loading Trolley

Adding a drag trolley on the basis of the hydraulic unwinding rack can quickly transport the new coil to the unwinding station, realizing fast coil change and greatly reducing production interruption time.

Related Products

Request A Quote

If you have any questions or require more detailed information about our roll forming solutions, please contact us by clicking on the link below.

Our product specialists will be in touch with you shortly to discuss your requirements!