CZ Purlin Roll Forming Machine CZ30030

CZ Purlin Roll Forming Machine CZ30030

CZ Purlin Roll Forming Machine CZ30030

Beenew CZ30030 CZ purlin roll forming machine compact and versatile, available in servo/motor versions for flexible production. Features 20 roll stations (87–95° adjustable flange rollers) for precision C/Z profiles (75–300mm width).

Motor version includes 13 exchange modules; servo version uses 20A double-row chains for smooth operation. Combines durable design, high efficiency, and modern aesthetics—ideal for standard or custom profiles. Invest in reliable, advanced technology trusted by industry leaders. Elevate your production today.

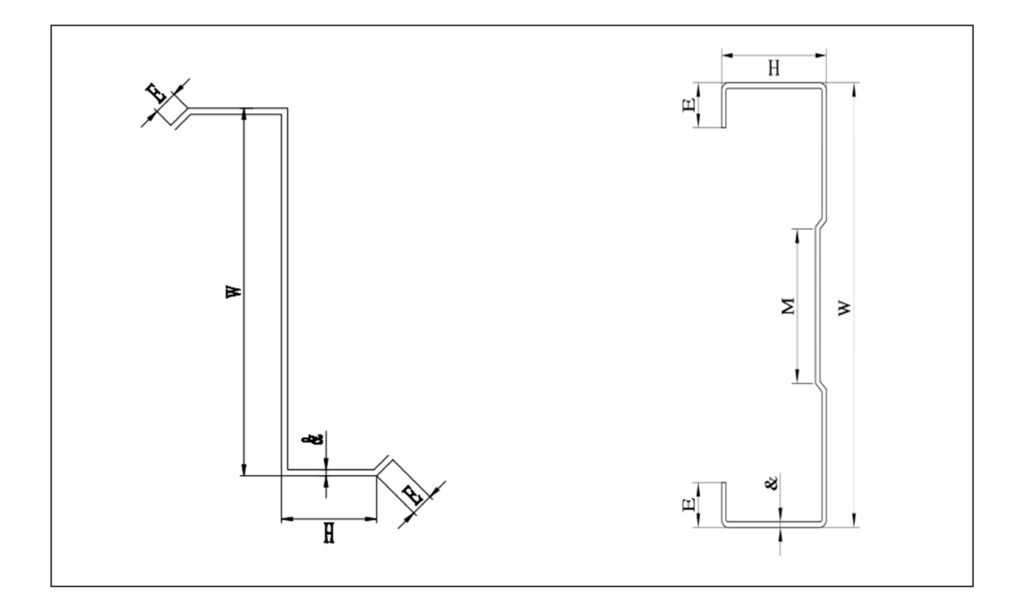

Profile drawing

Flow Chart

Uncoiler- Pre-Shearer- Flattening & Guiding -pre- punching & pre-cutting-Main Roll Forming Machine – Hydraulic Punching – Post Cutter -Product rack

Main Features of The CZ30030 Purlin Machine

Produce C80-300/Z120-300 purlins without roller/spacer changes.

Universal cutter for all sizes—no blade replacement needed.

Easy operation & low maintenance.

Infinite sizing (any within range)—optimizes material usage.

Optional punching: web/flange holes at any position.

Main Components Of The CZ Purlin Machine

1.Decoiler

Type:Manual decoiler or hydraulic decoiler

Load capacity:6T

2.Flattening and Guiding System

Flattening system: Upper 3 and lower 4 rollers plus additional pressure rollers are used to level the steel coils

Guiding system:Equipped with a guiding shaft and guiding rollers, its width can be adjusted to accommodate various steel strips.

Machine shaft: 40Cr quenched and tempered

3.Pre-punching device

Flat-sheet punching: PLC-controlled quantity/horizontal position; manual vertical adjustment

Web/flange punching: Fully customizable quantity & size

Quick-change punch bar/die for flexible setups

4.Pre-cutting device

Pre-cuts materials before roll forming

5.Main roll forming M/C

Drive: Chain

Max forming speed: 30m/min

Rollers: 19 groups (Cr12 steel)

Lower roller diameter: ~360mm

Shafts: Double-ground precision

Main shaft: ø95mm (40Cr steel)

Size adjustment: Auto/Semi-auto

C/Z interchange: Fast system (3 steps, 5-15 mins)

6. Hydraulic cutting

Innovative cutting system,integrated CZ-adjustable molds eliminate replacement needs during purlin size changes

7. PLC Control System

Control: Automated punching/cutting length & quantity

Operation: Auto-pause during punching/cutting cycles

Precision: Auto-length measurement & counting (±3mm)

8. Product rack

Type :2 sets, 3 meters each, free roller type

9. Product sample

Overview of other optional systems

Inkjet printing system: custom printing of company name, corporate logo, product code, etc. on purlin flanges

Pre-cutting mechanism: quick change of steel coils without affecting production flow

Flat plate pre-punching equipment: pre-punching and slotting operations

Automated stacking system: stacking of processed C- and Z-shaped purlins

Additional punching unit: supports additional installation of punching devices

Our factory

Why choose us

28-years expertise in CZ purlin roll forming

Cost-effective + reliable quality

2-years warranty included

24/7 after-sales support

Auto web adjustment (80–300mm in 2min)

Tailored solutions available

User-friendly & low maintenance

Self-developed cutter: Single blade for all sizes

Item | Parameters |

Driving Motor | 22.0KW |

Forming Speed | 30m/min |

Roller Material | GCR15 |

Shaft Diameter | φ80/65mm |

Shaft Material | 40Cr round steel quenching and tempering treatment |

Pump Motor | 7.5KW |

Cutting Type | Hydraulic Cutting |

Control System | PLC |

Punching group | 3 sets |

Related Products

Request A Quote

If you have any questions or require more detailed information about our roll forming solutions, please contact us by clicking on the link below.

Our product specialists will be in touch with you shortly to discuss your requirements!