C Channel Forming Machine: Industrial Production Essentials

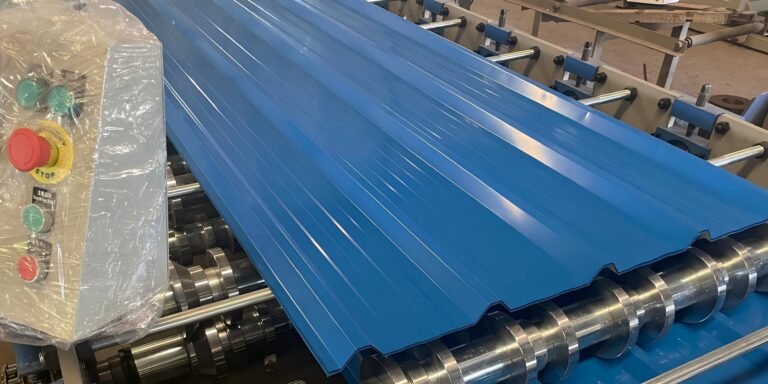

A C channel forming machine is a critical industrial asset designed to fabricate C-shaped or U-shaped metal profiles from flat coils or sheets. These structural elements are integral to construction, automotive frameworks, and machinery manufacturing. Below is an overview of its operation and related specifications:

1.How a C Channel Forming Machine Operates?

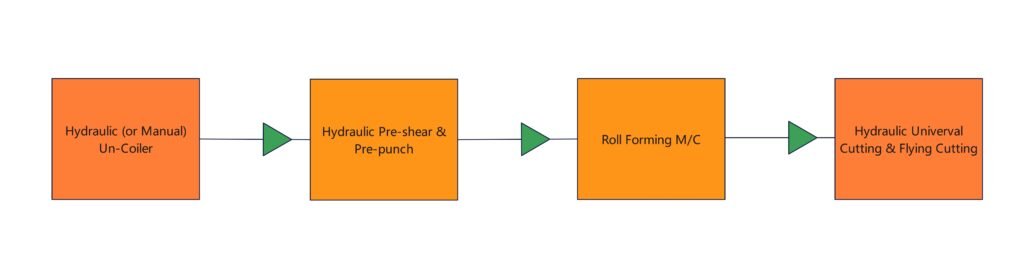

Here is rough flow chart for the producing line:

Material Feeding: Metal coils (steel, aluminum, etc.) are mounted onto a decoiler(manual or hydraulic expanding coil inner hole types), which feeds the strip into the roll forming system.

Straightening Phase: Initial rollers or levelers correct any curvature in the metal strip to ensure uniformity.

Profile Shaping: The C channel forming machine adopts a sequence of precision rollers to incrementally bend the metal into the desired C/U profile. Each roller station modifies the strip’s shape progressively.

Cutting Mechanism: Post-forming, automated shears (flying or hydraulic) cut the continuous profile into predetermined lengths.

Inspection Systems: Laser sensors or manual checks verify dimensional accuracy and surface quality.

Output Handling: Finished channels are stacked, bundled, or palletized for shipment.

2.Benefits of Using a C Channel Forming Machine

Rapid Production: Continuous processing enables high-volume output with minimal downtime.

Tailored Configurations: Adjustable rollers accommodate diverse channel dimensions (height, width, thickness) and materials.

Dimensional Accuracy: Tight tolerances (±0.5mm) ensure uniformity across batches.

Efficient Material Usage: Precision forming reduces scrap compared to stamping or machining.

Multi-Profile Capability: Retooling allows production of Z-channels, hat sections, and more.

3.C Channel Profile Specifications

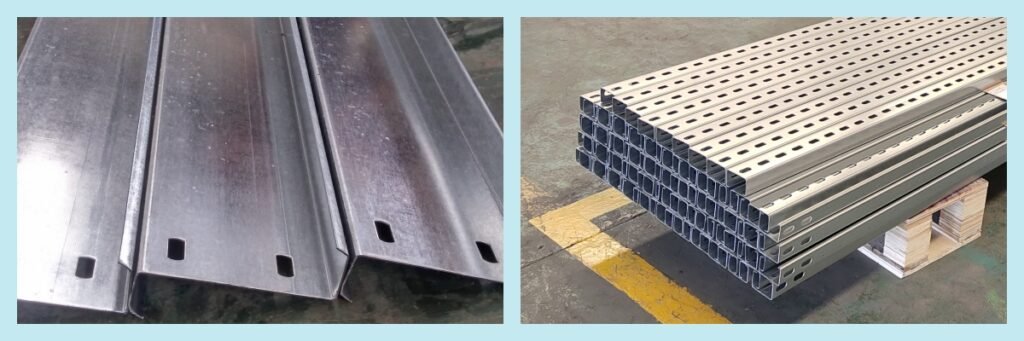

Galvanized C channels feature a horizontal flange with two vertical legs, forming a cross-section resembling the letter “C”. Common applications include:

Construction: Roof purlins, wall studs, and bridge supports.

Transportation: Vehicle chassis and trailer frames.

Energy Systems: Solar panel mounts and cable management trays.

4.Standard C Channel Dimensions

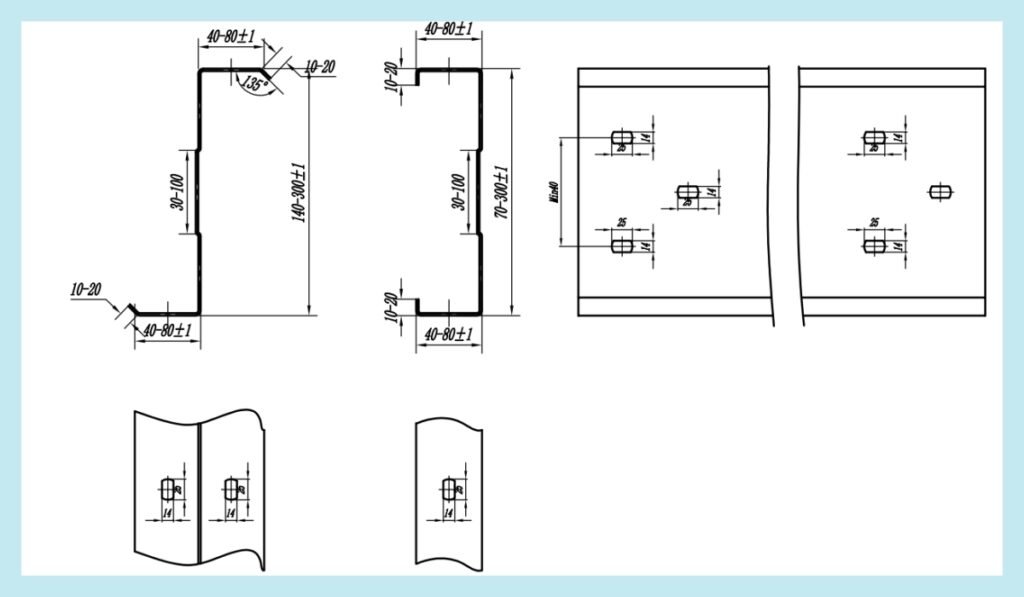

Light-Duty: Heights of 50–100mm, flange widths of 20–50mm, and thicknesses of 2–4mm.

Heavy-Duty: Heights up to 400mm, flanges of 60–100mm, and thicknesses of 6–12mm.

Metric Sizes: Common in Europe and Asia, ranging from 50x25mm to 250x100mm.

Popular Size Range: Height range: 80-300mm, flanges of 30-80mm and material thickness is 1.5-3.0mm, popular used in steel structure and solar channels application.

Customization: Manufacturers often tailor profiles to meet project-specific load capacities.

CZ300 Profile Design Drawing Details:

5.Why Choose Our C Channel Forming Machines?

Since 1997, we Xiamen Beenew has specialized in engineering kinds of roll forming machines, and developed auto change size C channel forming machines in 2015 year that adapt to evolving much more sizes ranges as kinds of industry needs. Our expertise ensures reliable solutions for structural and non-structural applications, backed by technical support for operational challenges.

By integrating advanced automation and modular designs, our C channel forming machines deliver efficiency and precision, solidifying their role in modern manufacturing. Contact us to explore configurations tailored to your production goals.

Below are some of our other channel making machines

To learn more about Channel roll forming machine

VIEW our YOUTUBE CHANNEL

About Beenew Machinery

BEENEW MACHINERY is a leading roll forming machine manufacturer and forming solution provider. We can meet various needs of forming machines in the construction industry, solar photovoltaic industry, and transportation industry. With more than 28 years of experience in forming machine manufacturing, we provide high-quality forming machines and innovative forming solutions to more than 50 countries around the world and have won the reputation of customers.

BEENEW roll forming machine manufacturer and supplier is located in Xiamen, China (one of the forming machine manufacturing bases in China). The factory has a full set of machines and equipment for producing roll forming machines for the production of forming machine parts.

All of Beenew machinery’s roll forming machines are professionally manufactured in China. Our goal is to provide forming machines with the best roll forming solutions, the best design, and the best quality to bring the greatest production benefits to our customers.

Hotline:+8618959261060(WhatsApp/Wechat)

Email:vin@beenewmachinery.com

Factory:No.5, Fuming Road, Tong’an Dstrict,Xiamen City,China