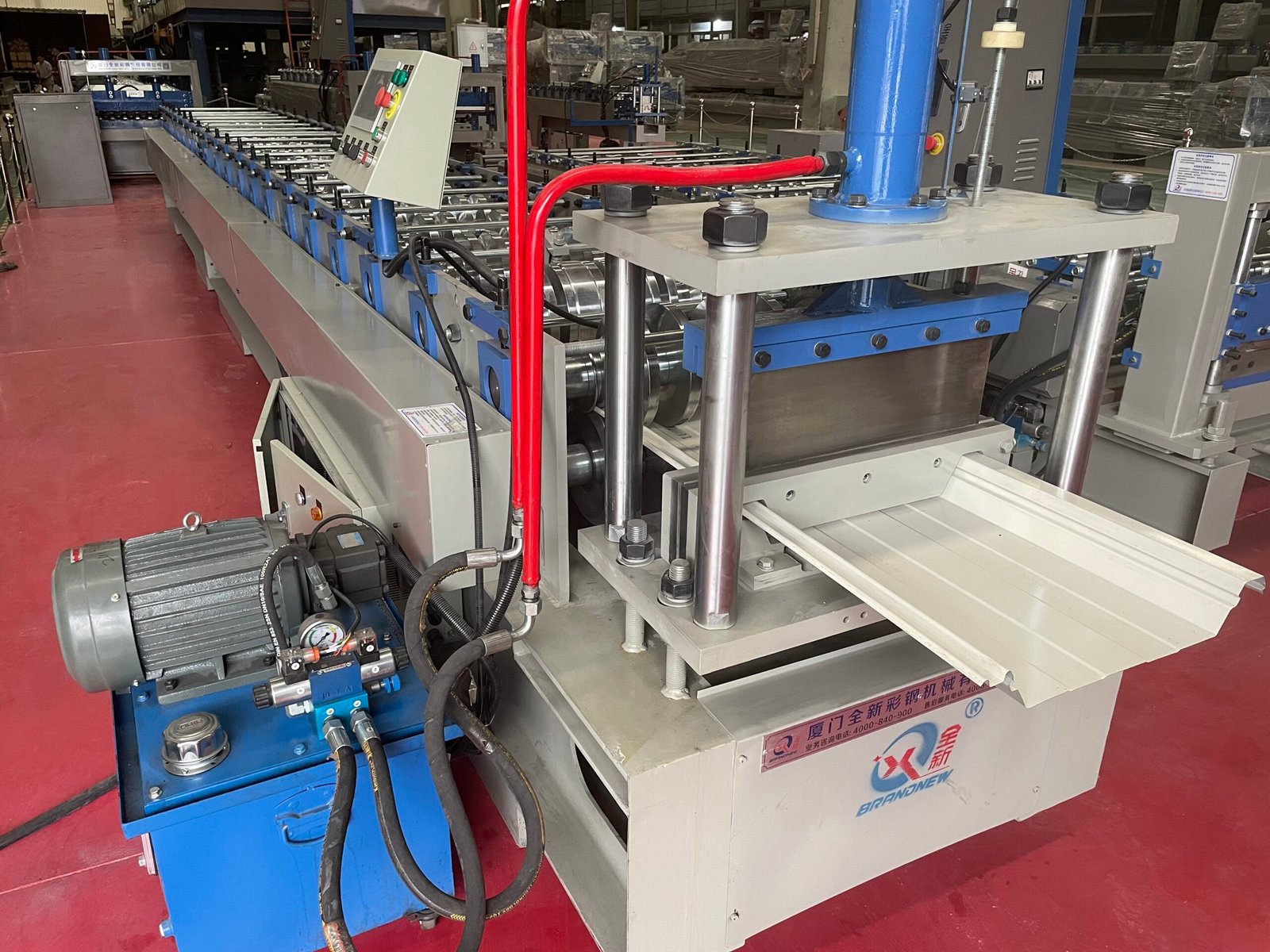

Straightening Machine for Sheet Metal

Straightening Machine for Sheet Metal

Straightening Machine for Sheet Metal

Straightening machine for sheet metal of Beenew is a 3 in 1 machine which can do straightening, slitting, and shearing in one machine. In other words, this machine can unfold, flatten, slit, and cut steel coils to length, and ultimately output high-quality, precise flat single-piece plates.

The machine’s main processes include:

Unwinding and Feeding

The included decoiler ensures smooth and automatic unwinding.

Leveling

Multiple staggered leveling rollers are used. Normally 9 rollers (4 upper rollers and 5 down rollers) are used to process 2.0mm thick sheets, while 13 rollers (6 upper rollers and 7 down rollers) are used for sheets 2.5-3.0mm thick coils. Repeated straightening can eliminate internal stresses and unevenness, then get a perfectly flat sheet suitable for subsequent precision processing or direct use. All rollers are made from Cr12 mould steel and fine processed to make sure long life and leveling effect.

Slitting

After the sheet is leveled, it passes through a slitting head equipped with multiple pairs of circular blades (upper and down). These blades can slit the wide coil into several narrow strips of the desired width, based on the set width. For example, a 1-meter-wide steel coil can be slit into five 20-centimeter-wide strips.

Shearing

After slitting (or without slitting), the flat sheet (or strip) is conveyed to the cut-to-length mechanism. When the material length reaches the set length, the machine will do automatically shearing. For example, a continuous steel strip can be cut into rectangular sheets measuring 1000mm x 200mm.

Related Products

Request A Quote

If you have any questions or require more detailed information about our roll forming solutions, please contact us by clicking on the link below.

Our product specialists will be in touch with you shortly to discuss your requirements!