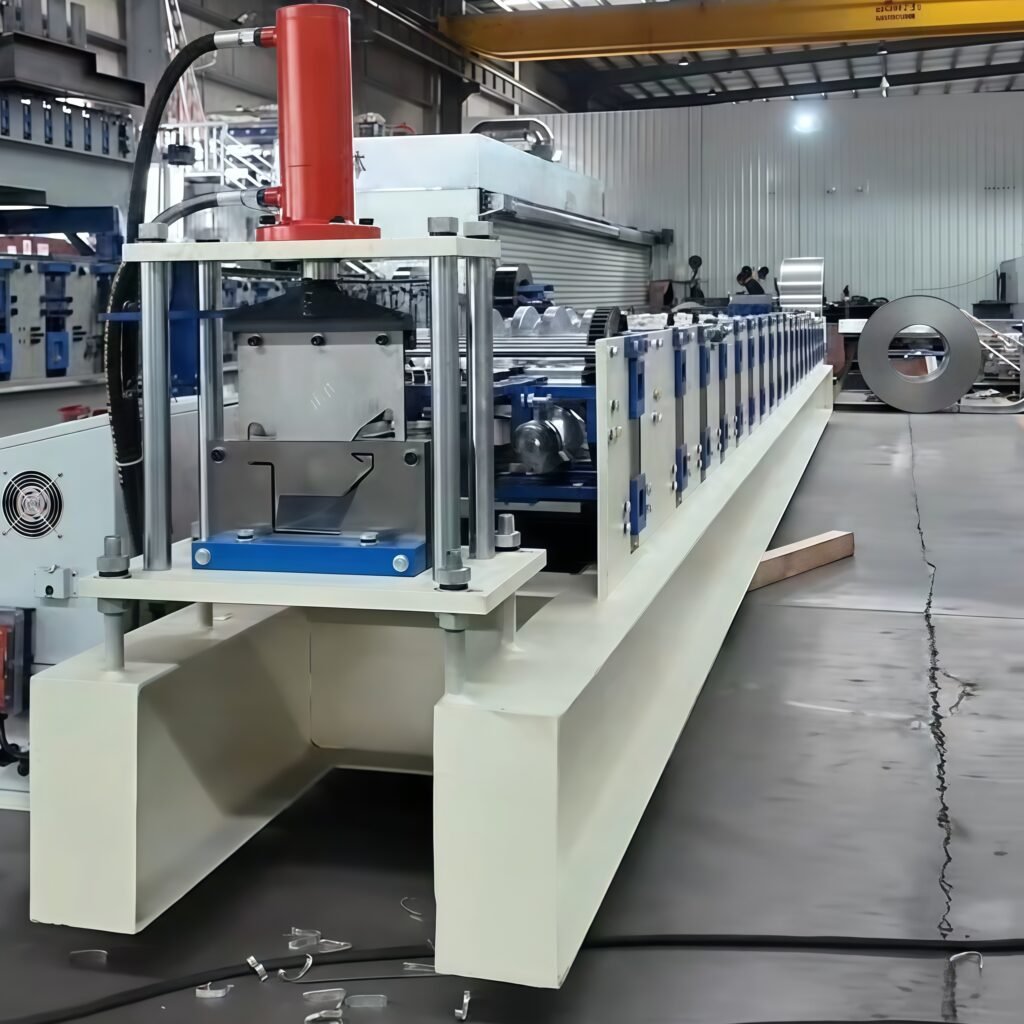

Product Display

This gutter machine is designed to deal with 0.5-0.8mm thickness PPGI coils. Totally 17 steps to form and the forming speed is about 18-20M/min. In order to make the machine short and compact so that it can be placed in a movable truck compartment, the machine’s uncoiler will be integrated on the main machine.

Details of the Gutter Machine

–Un-coiler

Intergrated on the main machine. Manual adjust type. Max. Loading capacity is 3 tons. Inner diameter is 450-530mm.

–-Main Machine

With material feeding guide. Machine frame adopts 250 H steel by welding. All rollers are made from #45 steel, CNC lathes, hard Chrome Coated; Totally 17 steps to form. And the forming speed is about 18-20m/min.

–PLC Control System

The entire line utilizes PLC control with a human-machine interface, enabling operator interaction with the PLC. The operator can run the set program automatically, monitor the control process, adjust production parameters, and oversee equipment status and fault indications in real time. The length is digitally set and can be adjusted as needed.

Combined with:PLC, inverter, Relay,Touch Screen, Encoder, etc.

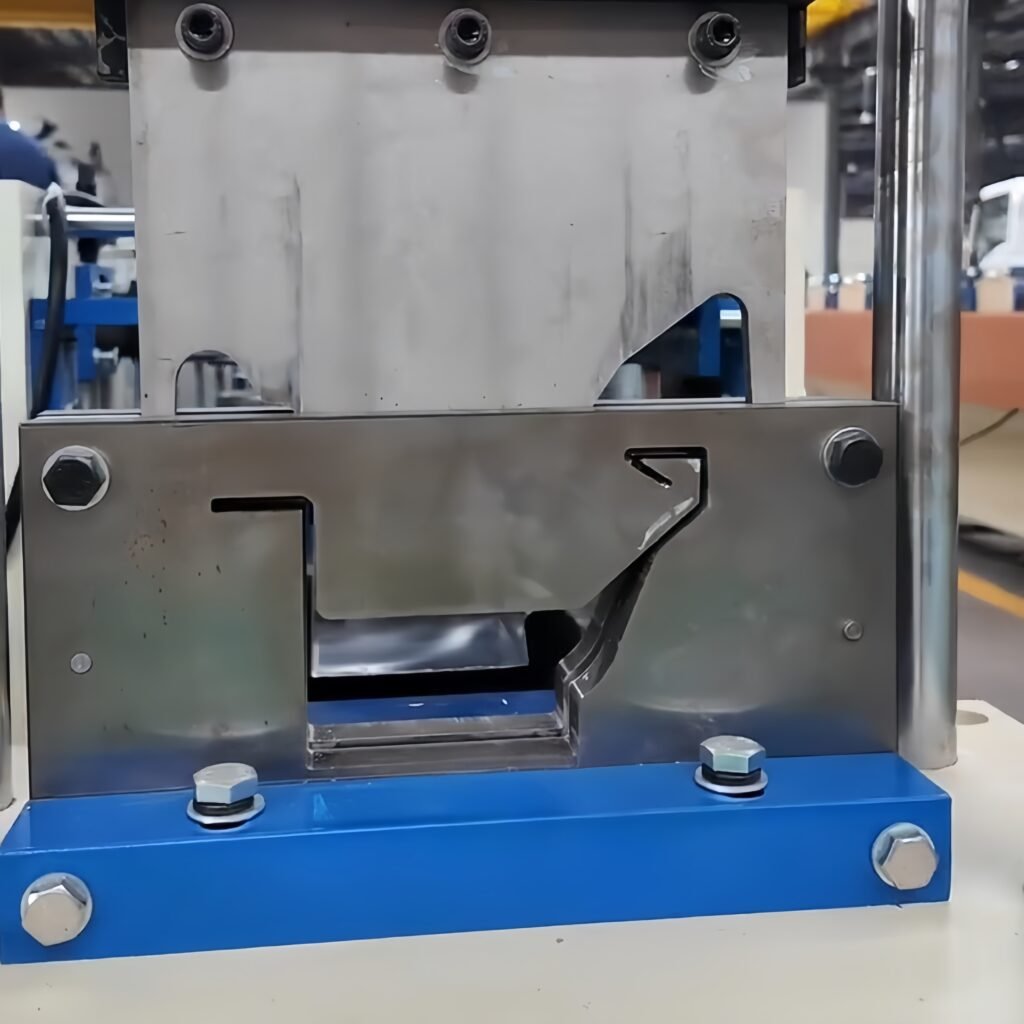

–Post Hydraulic Cutter

Hydraulic post cutter, three-blade structure; Cutting blade material CR12MVO;

If you have any questions or require more detailed information about our roll forming solutions, please contact us by clicking on the link below.

Our product specialists will be in touch with you shortly to discuss your requirements!