C/Z Purlin Roll Forming Machine

The C/Z purlin roll forming machine is a remarkable piece of equipment that can transform hot – or cold – rolled metal strips into C – type or Z – type purlins. It achieves this through a series of processes including leveling, cold roll forming, punching, and cutting. By simply changing the spacers, the machine is capable of producing purlins of various specifications, offering great flexibility in manufacturing.

The technical flow process of the C/Z purlin roll forming machine is as follows: First, the metal strip is decoiled from the coil. Then, it is fed into the machine. After that, the sheet goes through a leveling process to ensure it is flat. Next, punching is carried out according to the required length. Subsequently, the strip is cut to the appropriate length. After that, the roll – forming process takes place, which shapes the metal into the desired C or Z profile. Finally, the formed purlin is transferred to the run – out table.

With an impressive 30 – year history in the industry, Beenew Machinery has established itself as a specialist in manufacturing high – quality C/Z purlin roll forming machines. If you have any needs or inquiries regarding these machines, please do not hesitate to contact us!

Technical Parameter Of C/Z Purlin Roll Forming Machine

Item | Parameter |

Model | CZ-300 |

Profile | CZ purlin |

Purline specification | 80-300 |

Material | Steel strip |

Thickness(mm) | 2.0-3.0 |

Yield strength | Q230-345 |

Forming speed(m/min) | 25-30 |

Roller material | GCR12 MOV |

Roller driven type | Chain transmission |

Controller | PLC |

Operation | Touch screen and button |

Hydraulic system pressure(Mpa) | 20 |

Hydraulic station motor power(kw) | 7.5 |

Main motor power(kw) | 22.5*2 |

Total power(kw) | 55 |

Total weight(kg) | About 13000 |

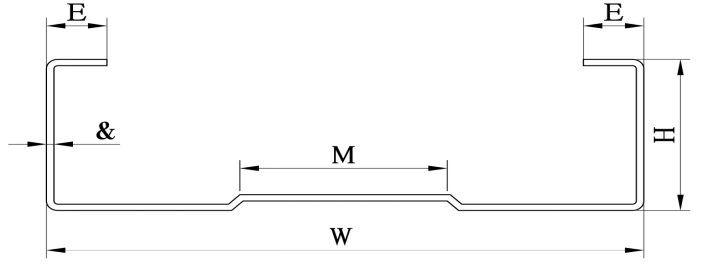

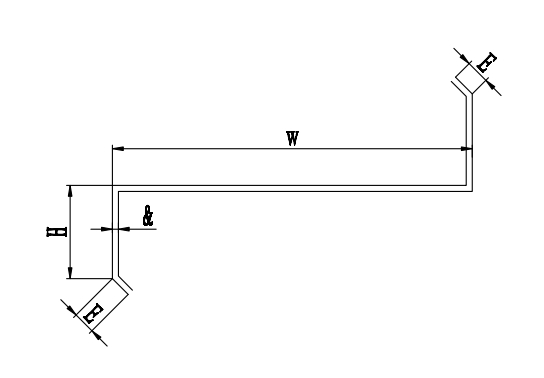

Profile Drawings Of C/Z Purlin Roll Forming Machine

Related Products

Request A Quote

If you have any questions or require more detailed information about our roll forming solutions, please contact us by clicking on the link below.

Our product specialists will be in touch with you shortly to discuss your requirements!