What materials can a roll forming machine process?

1.What materials can a roll forming machine process?

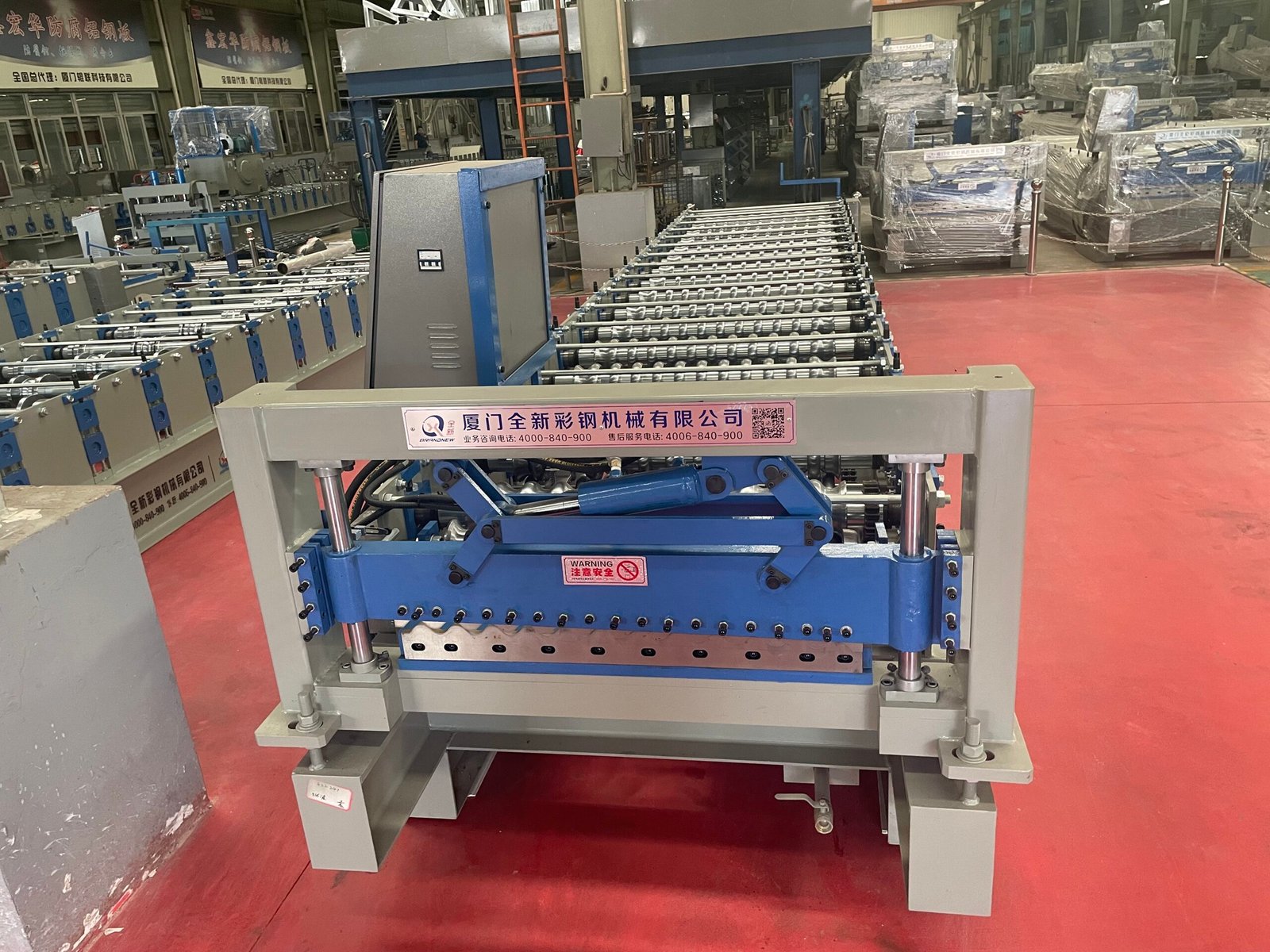

Roll Forming Machine is primarily used for the continuous processing of metal strips. Common materials it can handle include:

1.Low-carbon steel

Most widely used, suitable for building structural components (e.g., purlins, keels) and automotive parts.

2.Stainless steel

High corrosion resistance, used in food processing equipment, architectural cladding panels, and industrial equipment housings.

3.Aluminum and aluminum alloys

Ideal for lightweight applications, such as automotive body parts, appliance housings, and solar mounting brackets.

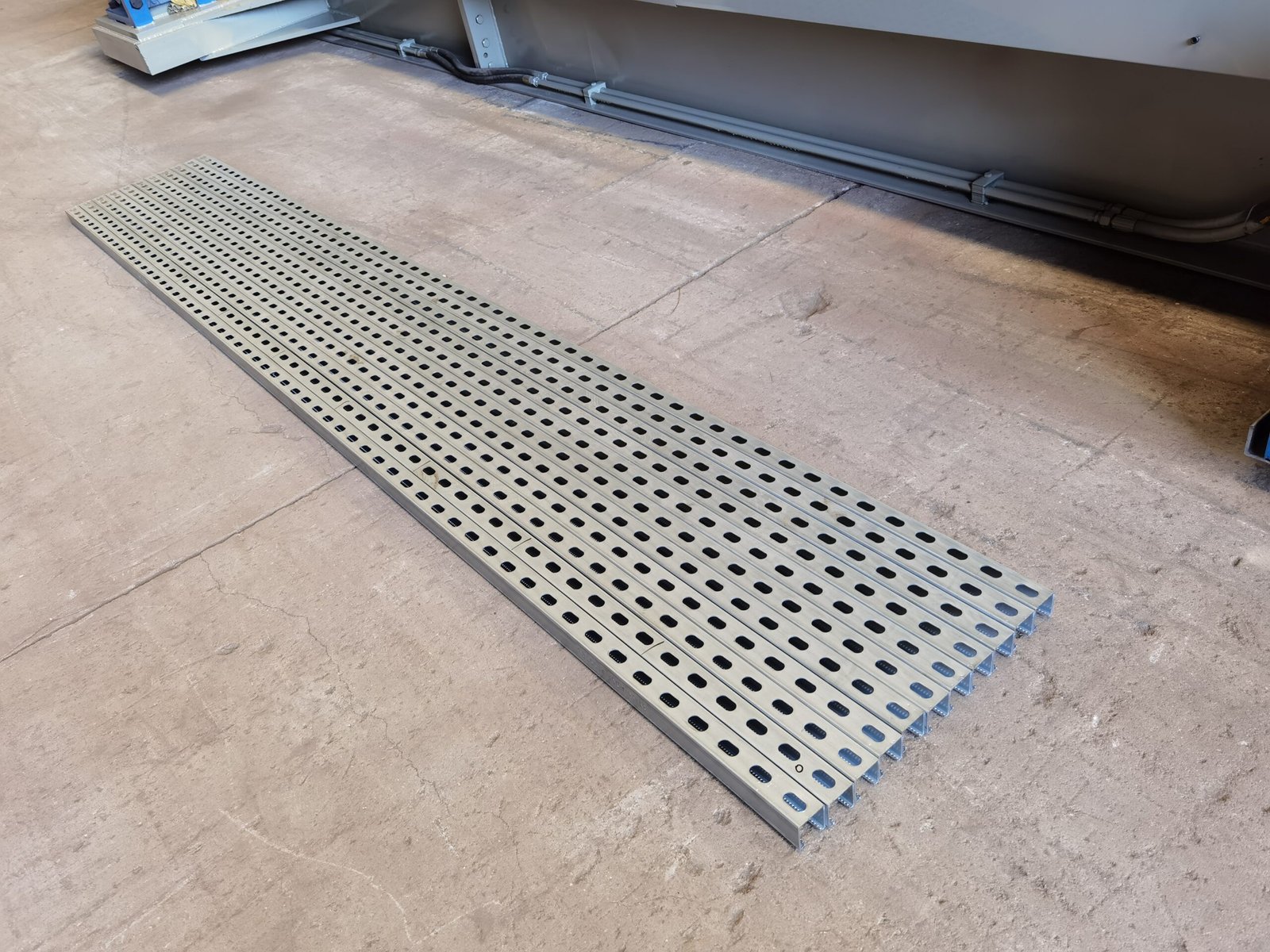

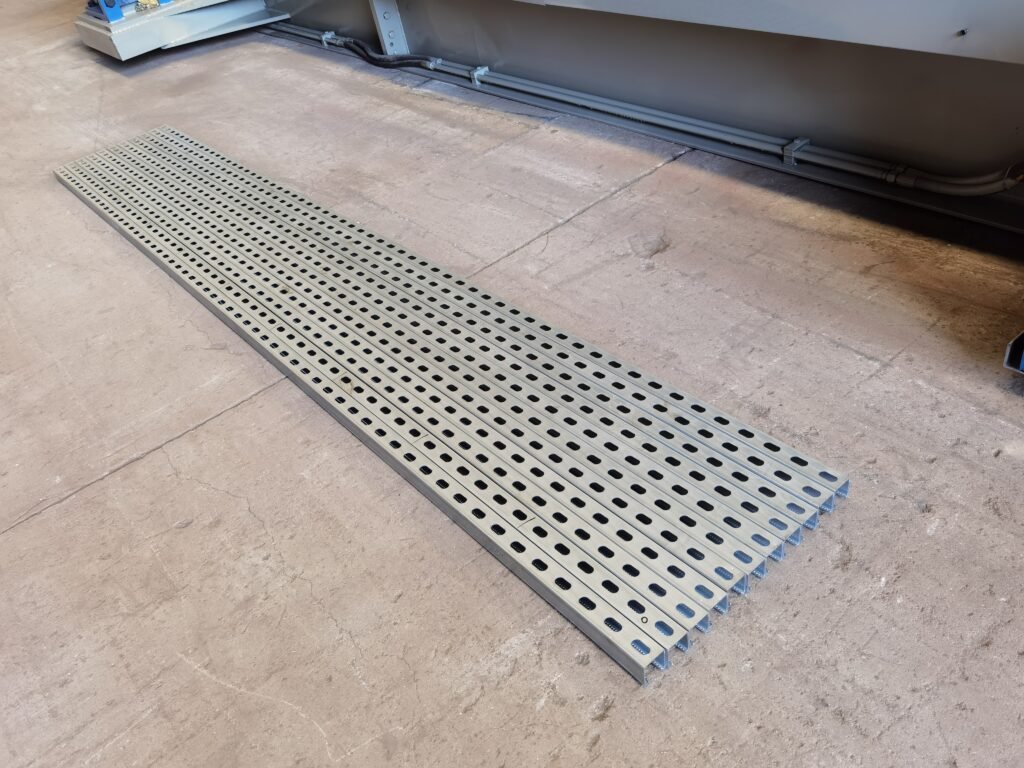

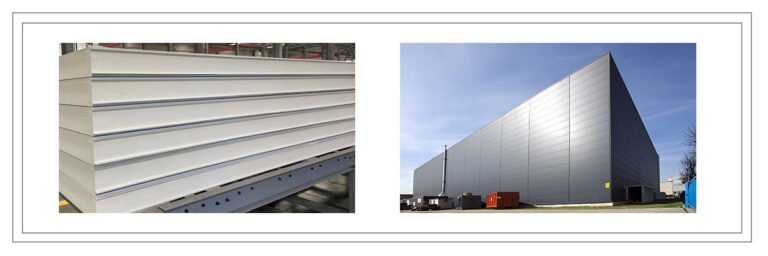

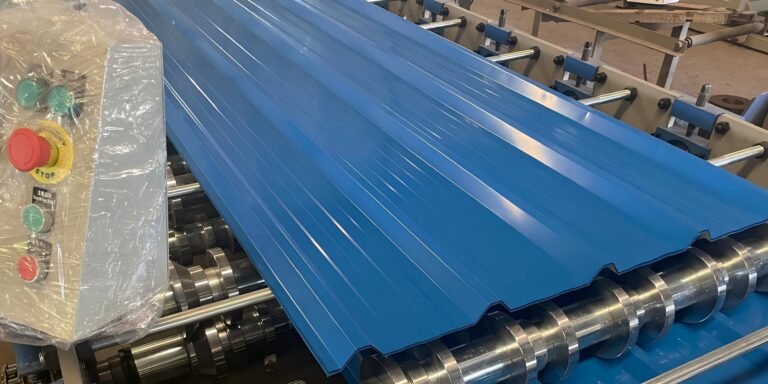

4.Coated/painted steel

Galvanized steel (rust-resistant), color-coated steel plates (pre-painted colors or coatings), commonly used in roofing, wall panels, and other construction applications.

5.High-strength steel (HSS)

Required for high-load-bearing structural components, such as truck frames and shelf support beams; requires high-power equipment.

6.Copper/brass

Used for specialized decorative strips and conductive components, though applications are relatively limited.

The thickness range which a roll forming machine can deal with:

Typically 0.1mm to 20mm (depending on equipment model and material strength).

Notes:

Materials must have sufficient ductility to avoid cracking during forming.

High-hardness materials (e.g., certain alloys) may require preheating or specialized roll-forming processes.

Coated materials require controlled rolling pressure to prevent surface damage.

2.What are the different requirements for processing various materials on a roll - forming machine?

When processing different materials on a roll – forming machine, specific adjustments and considerations are necessary to guarantee the best quality and efficiency. Below are the key requirements based on materials and applications:

1. Since low – carbon steel has high ductility and moderate strength, standard roll – forming setups are usually enough. Only a small amount of lubrication is needed, except when high – speed production is carried out. It is commonly used in structural components such as purlins and automotive parts.

2.Higher roll pressure and slower processing speeds are required to prevent work hardening and surface scratches when dealing with stainless steel.

Specialized tooling, like polished rollers, should be used to avoid contamination and maintain its corrosion resistance.

It is frequently used in food processing equipment or architectural cladding.

3.For aluminum and aluminum alloys, the roll pressure should be reduced because of the low strength of these materials to prevent deformation.

Temperature needs to be controlled to avoid overheating, which can lead to warping. They are used in lightweight automotive parts and solar panel brackets.

4. As for pre-coated coils, precise pressure control is essential to avoid damaging the pre – applied coatings, such as galvanized or color – coated layers. Rollers with smooth surfaces or protective sleeves should be used to minimize scratches caused by friction. It is commonly used in roofing and wall panels.

5.For High – Strength Steel (HSS):

High – power equipment is needed to deal with the increased resistance of the material when dealing with high strength steel. Advanced roll tooling, like carbide – coated rollers, can reduce wear. For thicker grades, preheating may be necessary to improve formability. It is often used in truck frames and heavy – duty shelving.

6.Soft rollers or non – metallic coatings should be used to prevent surface marring if it is copper or Brass. Rollers need to be cleaned frequently to avoid material buildup. Due to cost and niche applications, it is mainly used for decorative or conductive components.

3.General Considerations

Thickness Range: Different materials have different processing thickness range. We need to adjust according to specific materials and machine capacities.

Ductility: Materials with low ductility, such as some alloys, may need intermediate annealing steps during the forming process.

Surface Finish: Pre – coated or polished materials require careful handling to maintain their integrity.