How does a roll forming machine work?

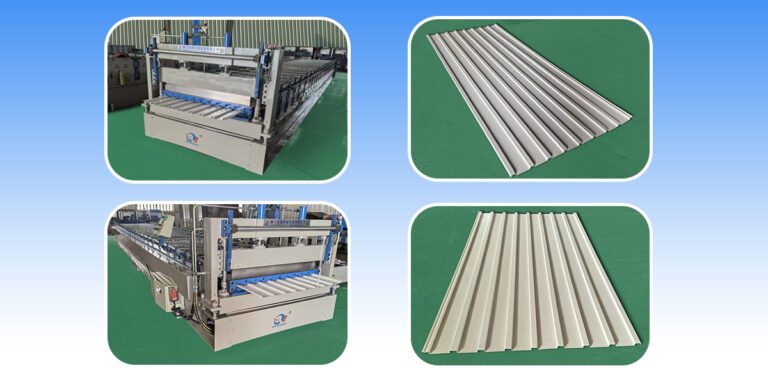

1.What is a roll forming machine?

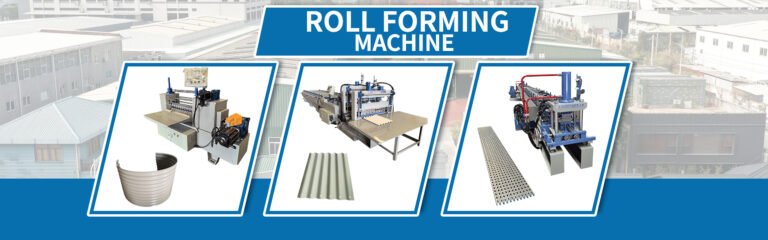

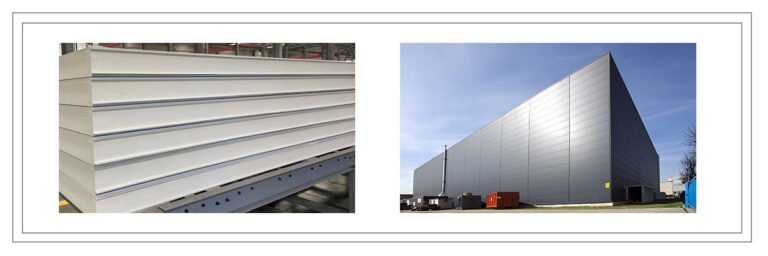

Roll forming machines are important production equipment in modern manufacturing and are widely used in industries such as construction, automotive and aerospace. This machine can process flat metal sheets or strips into various complex cross-sectional shapes with high precision and efficiency.

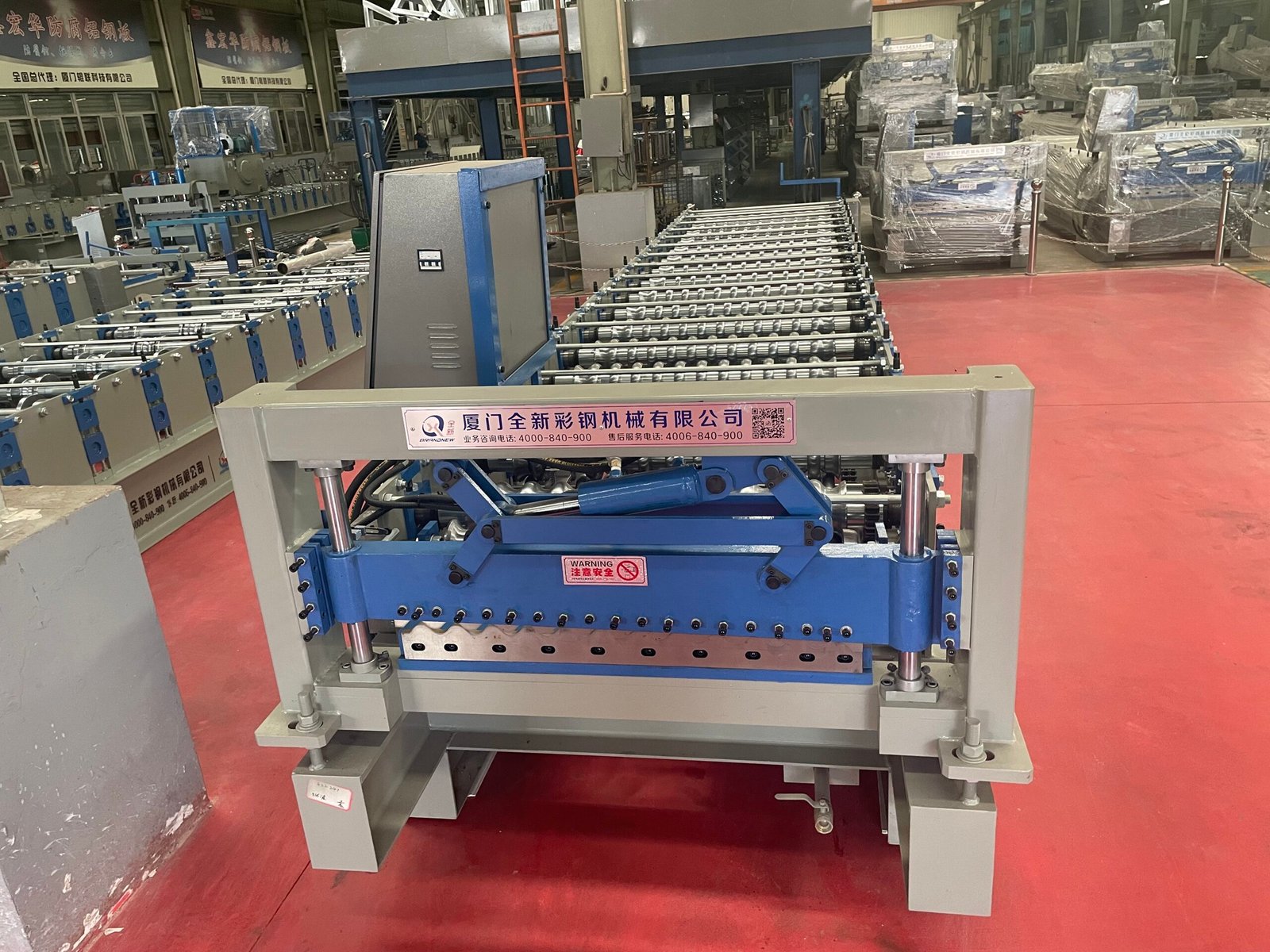

Beenew Machinery produces 1,000 roll forming machines every year and is a leading manufacturer in China. In the past 30 years, we have more than 6,000 customers in more than 50 countries around the world.

2.Overall structure of roll forming machine

The roll forming machine consists of several key components, each of which plays a specific role in the forming process. These components include the forming host such as the uncoiler, feeding system, rollers, rollers, cutting devices and control systems. Most of the spare parts of Beenew roll forming machines are produced independently by our factory to ensure the stability of the machine quality.

Uncoiler

The uncoiler is the starting point of the roll forming process. It is used to fix the metal coil, which can be made of materials such as steel, aluminum or stainless steel. The uncoiler is used to smoothly unwind the coil and feed the metal strip into the subsequent parts of the machine. It is usually equipped with a brake system to control the tension of the strip during the unwinding process to ensure a consistent and stable feeding speed. There are two types of uncoilers: manual uncoilers and hydraulic uncoilers, which we configure according to customer needs. The hydraulic uncoiler costs a little more, but it can save manpower and improve efficiency.

Feeding system

After the metal strip is unwound from the uncoiler, it enters the feed guide. The feed guide is responsible for properly aligning the strip and guiding it to the first set of roller frames. It helps prevent the strip from deviating or tilting, thereby avoiding inaccurate forming or machine damage. The feed guide contains adjustable rollers or guides to accommodate metal strips of different widths and thicknesses.

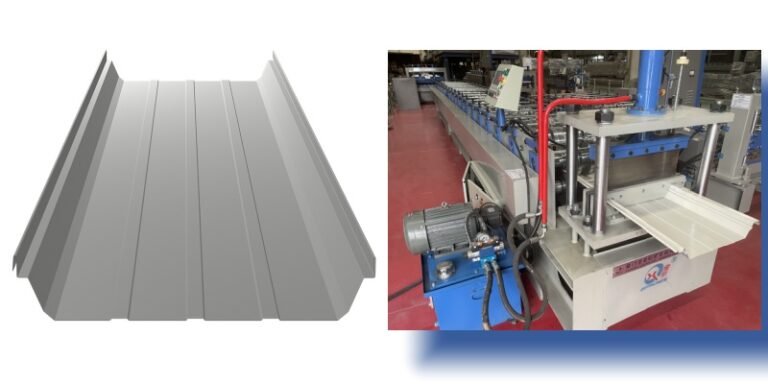

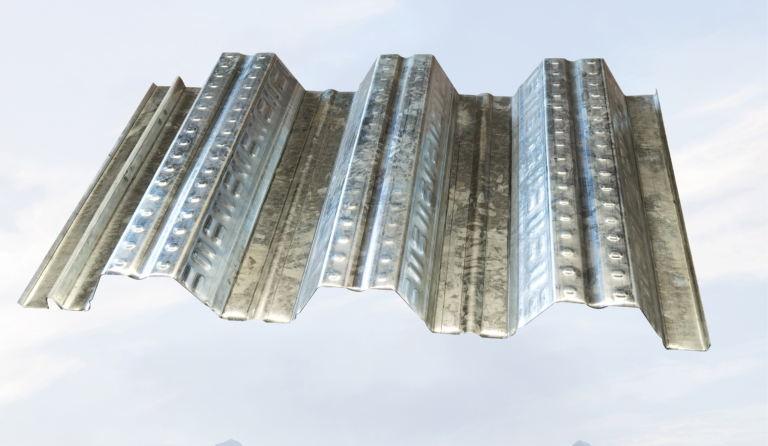

Rollers

The rollers are the core components of the roll forming machine. They are arranged in a linear sequence, and each roller contains one or more pairs of forming rollers. These rollers are precisely machined and designed to gradually bend the metal strip into the desired shape. Beenew Machinery uses rollers of different materials according to the requirements of different products, such as GCR12, CR12, CR12MOV, etc.

Roller Design

The design of the forming roller is crucial to the success of the roll forming process. The shape of the roller depends on the cross-sectional profile of the final product. For example, if the desired product is a C-shaped channel steel, the roller will be designed with a corresponding curvature so that the strip is gradually formed into a C shape. The roller is usually made of high-strength steel or other wear-resistant materials to withstand the high pressure and friction during the forming process.

Cutting Device

After the metal strip is formed into the desired shape, it needs to be cut into the required length. The cutting device is responsible for this task. There are many types of cutting devices used in roll forming machines, including mechanical shears, flying shears, and laser cutting.

Mechanical Shears

Mechanical shears are the most common cutting devices. They work by using a pair of blades to cut the metal strip. The blades are driven by a mechanical or hydraulic system, and the cutting process is usually synchronized with the movement of the metal strip to ensure a clean and accurate cut.

Flying Shears

Flying shears are used in situations where continuous production is required, and customers with high production efficiency requirements configure this shearing device. They can cut the metal strip while it is in motion, increasing productivity. Flying shears use a rotating blade or a set of blades that move in sync with the metal strip to precisely cut to the required length.

Learn more about the different types of roll forming machines here, or contact Beenew Machinery’s technical team for roll forming solutions.