What is a Roll Forming Machine?

1.What is a Roll Forming Machine?

In the modern industrial manufacturing arena, a roll forming machine is a key and indispensable piece of equipment that has a far – reaching impact on numerous industries, especially those related to metal processing and building material production.

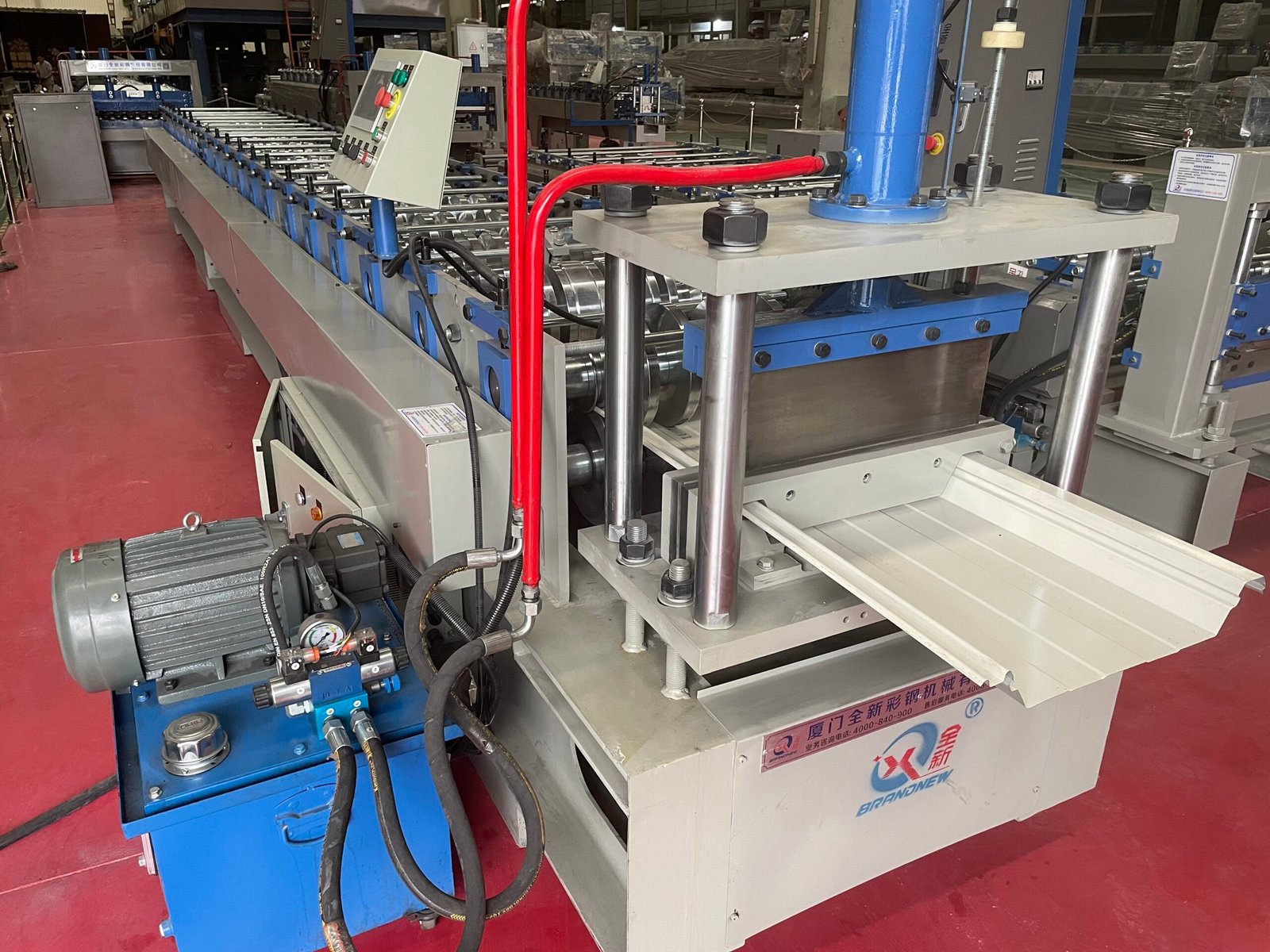

Beenew Machinery is a leading roll forming machine manufacturer in China. With nearly 30 years of industry experience, we have provided efficient and stable roll forming machine solutions and machine production lines to customers in more than 50 countries around the world.

2.The Basic Principle of a Roll Forming Machine

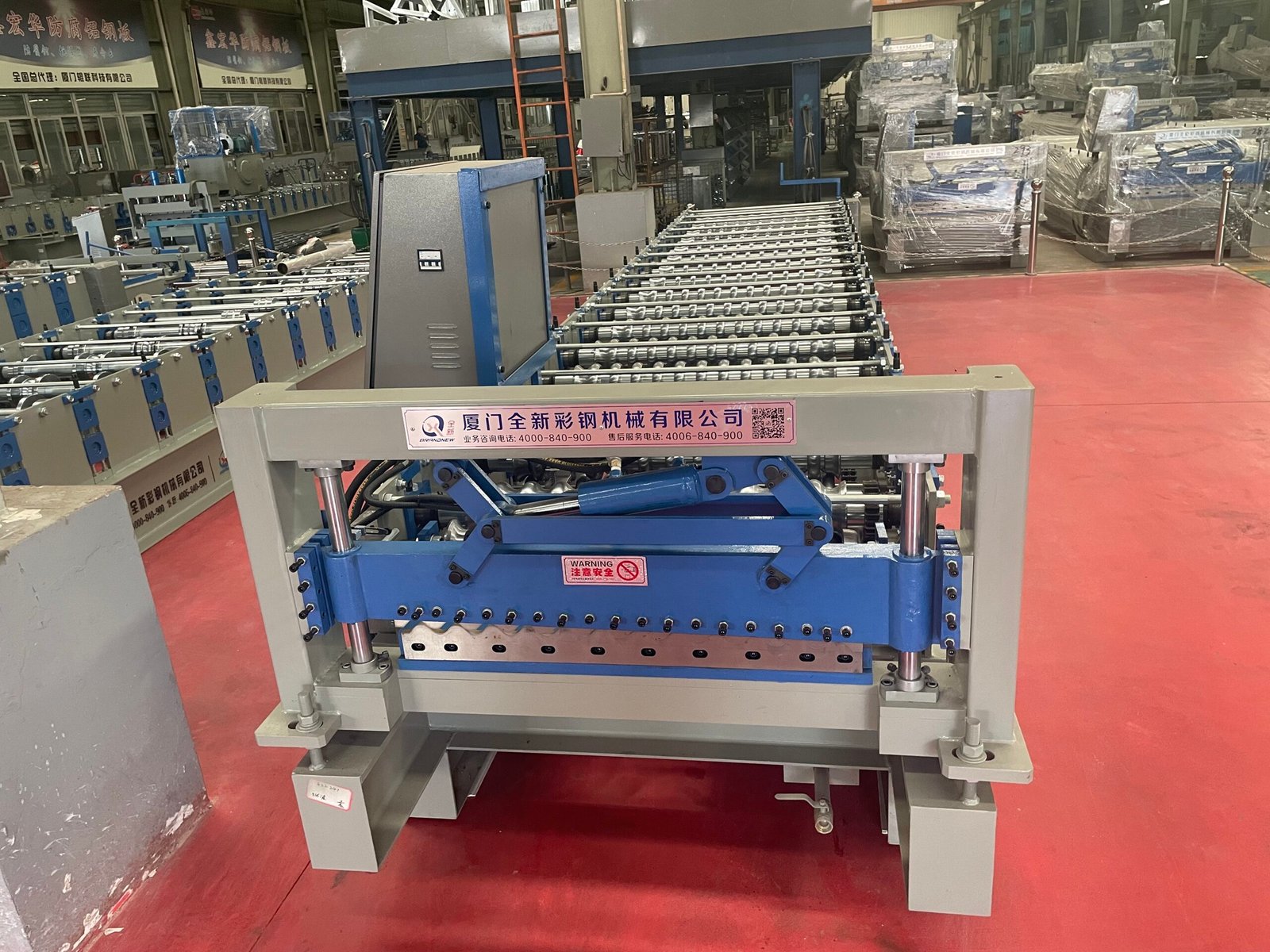

he fundamental principle of a roll forming machine is centered on continuous bending deformation. It mainly consists of a decoiler, an in – feed guiding platform, a main forming section, a punching device, a cutting unit, and a discharge platform. When a metal strip or sheet is unwound from the decoiler, it is guided into the main forming section through the in – feed guiding platform. Inside the main forming section, there are typically multiple sets of forming rolls arranged in a pre – defined sequence. As the metal material continuously passes through these forming rolls, each set of rolls exerts a specific amount of pressure on the material, causing it to gradually bend and transform into the desired shape. After traversing all the forming rolls, the metal material is finally shaped into the required form, such as various cross – sectional profiles and pipes. This continuous forming method not only boosts production efficiency but also guarantees the dimensional accuracy and surface quality of the products.

3.Types of Roll Forming Machines

Roll forming machines can be classified in several ways. Based on the forming process, they can be divided into cold – roll forming machines and hot – roll forming machines. Cold – roll forming machines process metal materials at room temperature and are suitable for most common metals, including carbon steel, stainless steel, and aluminum alloy. They are characterized by high processing accuracy, high production efficiency, and low cost, and are widely used in industries such as construction, automotive, and household appliances. In contrast, hot – roll forming machines shape metal materials under heated conditions. They are mainly used for materials that are difficult to form at normal temperature or for products with specific performance requirements. For example, in the aerospace industry, the forming of some high – strength alloy materials often requires the use of hot – roll forming technology.

According to their applications, roll forming machines can be further classified into general – purpose and special – purpose types. General – purpose roll forming machines can produce a diverse array of products with different shapes and sizes by changing the forming rolls. This gives them great flexibility and adaptability. Special – purpose roll forming machines, on the other hand, are designed for specific products or industries. For instance, there are machines specifically for producing color – coated steel sheets for construction or manufacturing automotive door and window frames. These special – purpose machines usually have higher production efficiency and better product quality but a relatively limited application range.

4.Application Fields of Roll Forming Machines

Construction Industry

Roll forming machines are extensively employed in the construction industry. They can produce a variety of building profiles, such as light – gauge steel studs, color – coated steel sheets, and aluminum alloy doors and windows. Light – gauge steel studs, as a novel building material, have the advantages of light weight, high strength, and easy installation. They are widely used in interior decoration and building structures. Roll forming machines can efficiently manufacture light – gauge steel studs of different specifications to meet the needs of various construction projects. Color – coated steel sheets are building panels with good insulation, heat – resistance, and waterproof properties. They are commonly used for the roofs and walls of industrial plants, warehouses, and residential buildings. Through roll forming machines, color – coated steel sheets can be formed into various shapes, enhancing the aesthetic and functional aspects of buildings.You can know more about our Roll Forming Machine:

CZ Purlin Roll Forming Machine

Metal Roofing Sheet Making Machine

Corrugated Sheet Making Machine

Automotive Industry

Roll forming machines also play a significant role in the automotive manufacturing process. They can fabricate automotive body frames, door and window frames, seat frames, and other components. These components usually require high strength and precision to ensure the safety and comfort of the vehicle. Roll forming machines can accurately produce components of different shapes and sizes according to automotive design requirements and enable large – scale production, improving the efficiency and quality of automotive manufacturing.

Household Appliance Industry

In the production of household appliances, roll forming machines are used to make the shells and frames of refrigerators, washing machines, air conditioners, and other appliances. These shells and frames need to have good appearance quality and dimensional accuracy to meet consumers’ expectations for the aesthetics and practicality of household appliances. Roll forming machines can produce household appliance components with smooth surfaces and accurate dimensions through precise forming processes, enhancing the overall quality of household appliances.

5.Development Trends of Roll Forming Machines

With the continuous progress of technology and the development of industrial manufacturing, roll forming machines are constantly evolving. In the future, roll forming machines will develop in the directions of automation, intelligence, high – precision, and environmental friendliness.

In terms of automation, more and more roll forming machines will be equipped with advanced automated control systems. These systems will enable functions such as automatic feeding, automatic forming, and automatic cutting, reducing manual labor and improving production efficiency and product quality. Intelligence will be reflected in the equipment’s ability to monitor the operating status of the machine and product quality in real – time through sensors and data analysis technology. This will allow for automatic adjustment of process parameters to optimize the production process and achieve intelligent management.

High – precision is an important development direction for roll forming machines. As the precision requirements of products in various industries continue to increase, roll forming machines need to continuously improve forming accuracy and dimensional stability. By adopting advanced forming technologies and high – precision processing equipment, future roll forming machines will be able to produce more precise products.

Environmental friendliness is also an inevitable trend for the development of roll forming machines. During the production process, roll forming machines will pay more attention to energy conservation, emission reduction, and environmental protection. For example, they may use new energy – saving motors and transmission systems to reduce energy consumption and optimize the forming process to minimize waste and pollutant generation.

In conclusion, as an important piece of equipment in modern industrial manufacturing, roll forming machines have a wide range of applications in various industries. With the continuous advancement of technology, they will play an even more important role in improving production efficiency, ensuring product quality, and promoting industrial development,like Cable Tray Roll Forming Machine.