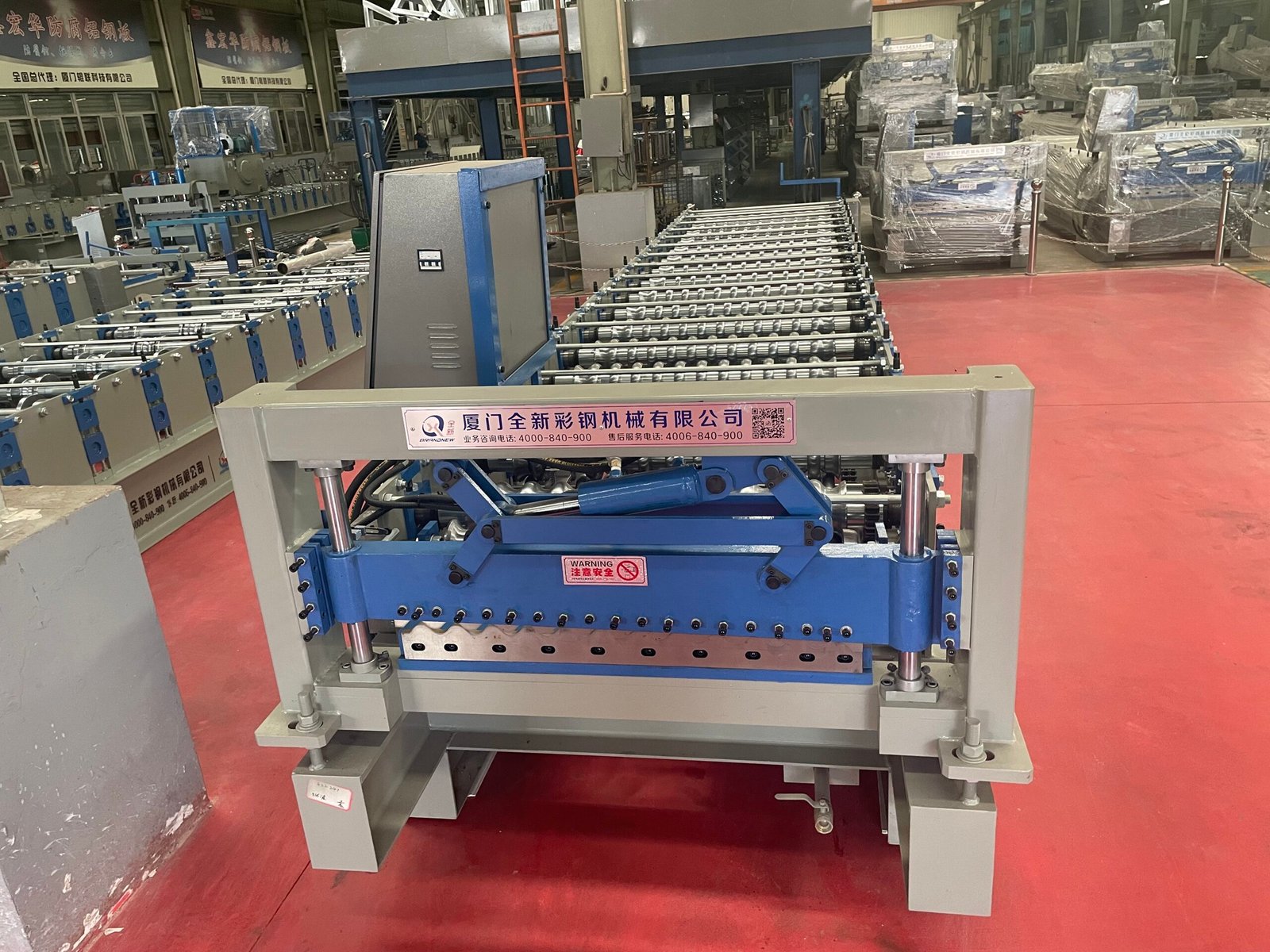

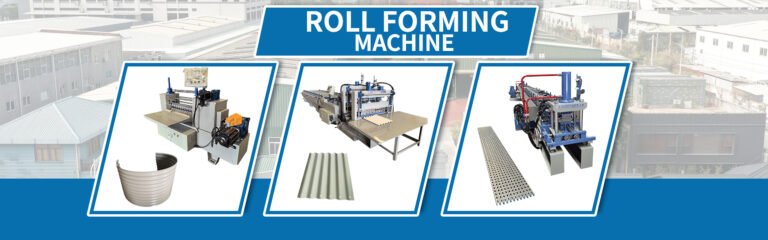

Polyurethane Sandwich Panel Production Line: Leading the Way in Energy – Efficient Building Applications

Polyurethane Sandwich Panel Production Line plays a crucial role in energy – efficient building applications:

Product Features Enabling Energy Efficiency

The polyurethane sandwich panels produced by the production line have excellent insulation properties. They are made with a core material that can effectively prevent heat transfer, which helps maintain a stable indoor temperature. For example, Tianfon polyurethane energy – saving panels have features like insulation, heat prevention, and soundproofing. The fire – retardant inside the PU panel also contributes to safety while maintaining energy – efficient performance .

Structural and Design Advantages

Lightweight and High – strength: The panels are lightweight yet high – strength, which reduces the overall load on the building structure. This not only simplifies the construction process but also can save on construction materials and energy during the building process. Tianfon’s panels are light – weight, innovative, and beautiful in appearance, with high – strength, stability, impact resistance, good anti – seismic and anti – corrosion properties .

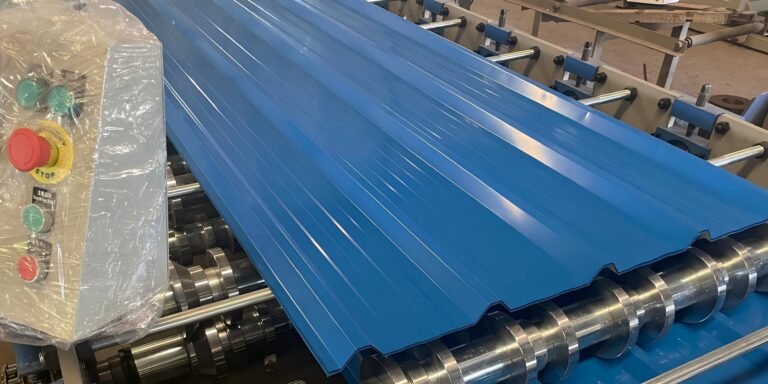

Customizable Design: The production line can produce panels in various sizes and thicknesses, such as finished sandwich panel thickness ranging from 30 – 200mm, width from 600 – 1200mm, and length from 2000 – 16000mm. This allows for flexible design in building construction, meeting different architectural requirements and optimizing energy – efficient design .

Application in Different Building Parts

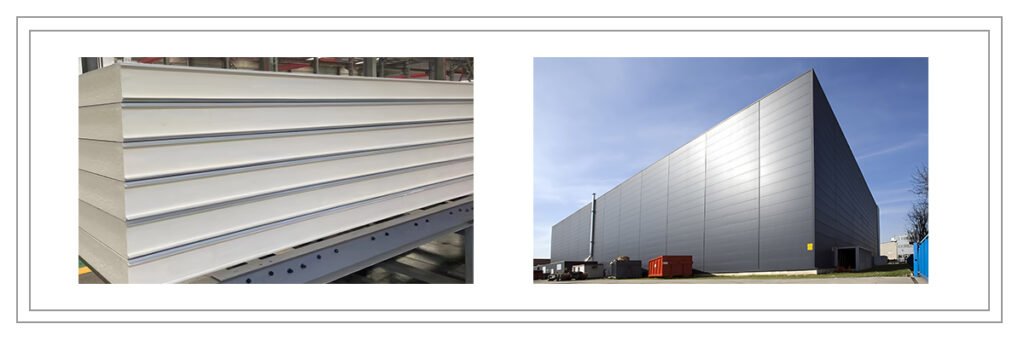

Wall and Roof Applications: Polyurethane sandwich panels are widely used in building walls and roofs. Tianfon’s wall panels system meets the requirements of building facades, and its A – type roof panels system is suitable for roofs with more than 3% incline in various industrial and commercial buildings. The fluid mechanics waterproof design at the joint points ensures good air – seal and water – proofing performance, reducing energy loss caused by air leakage and water seepage .

Cold Storage and Special Environments: The panels are also used in cold storage rooms and warehouses. Their insulation properties help maintain a constant temperature and prevent heat loss, resulting in energy efficiency and cost savings.

Construction Efficiency and Energy Saving

The high pre – fabricated nature of the panels produced by the production line shortens the construction period by about 40% compared to traditional construction methods. This reduces on – site energy consumption during construction and allows for quicker occupancy of the building, enabling earlier realization of energy – efficient operation .