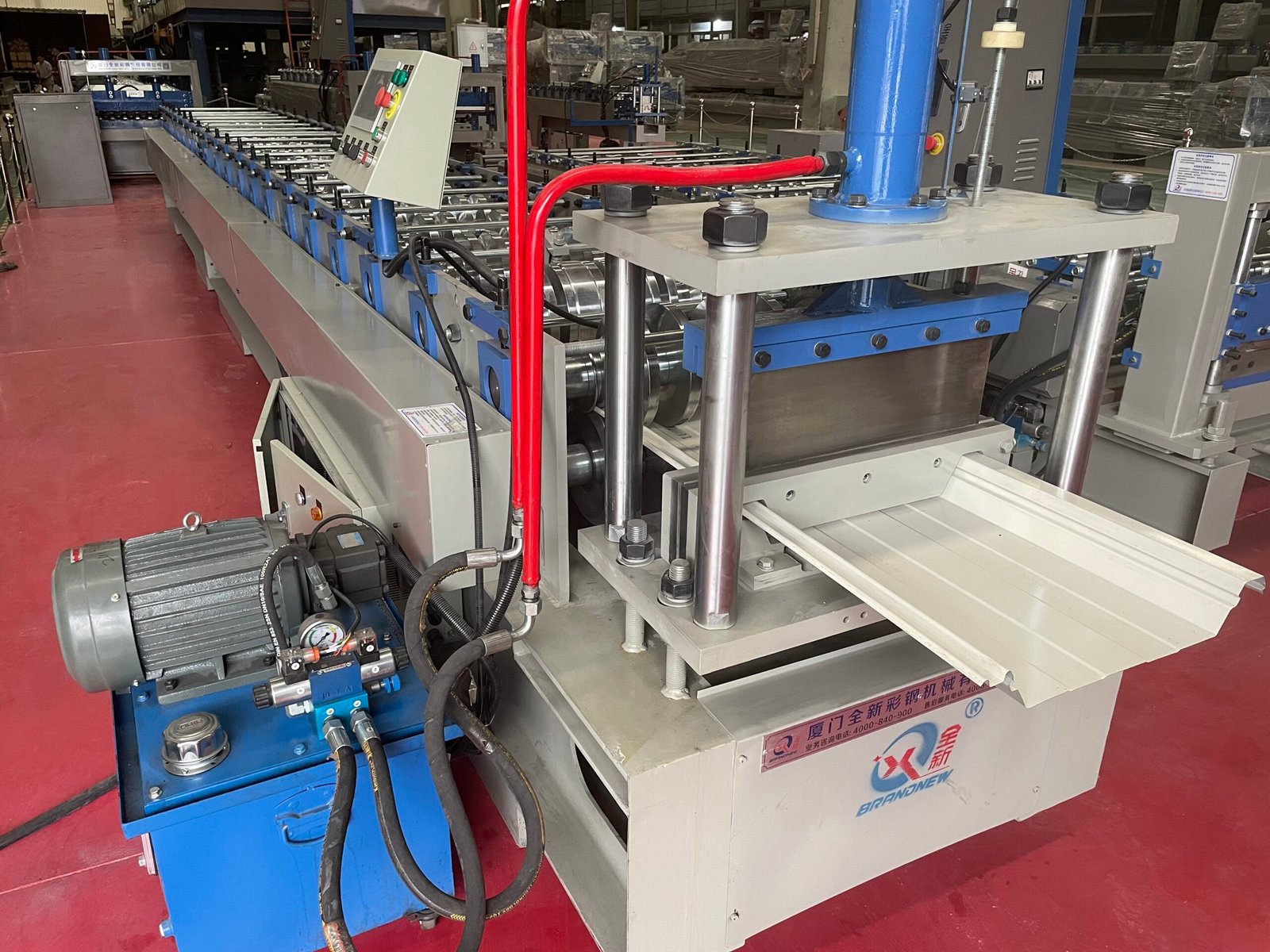

Rolling shutter making machine

Rolling shutter making machine

Rolling shutters and rolling grilles have a distinct advantage in terms of space utilization as they require only a small amount of headroom above the structural opening. When not in use, they roll up in a compact manner behind the lintel. This design ensures that no precious hall space is sacrificed at the sides of the opening or the ceiling area, allowing for more efficient use of the available space.

Beenew Machinery Rolling Shutter Machine, Door shutter DESIGN stands out as a professional manufacturing facility in China. We have the expertise and capabilities to supply a wide variety of roll – forming machines tailored to different types of shutter doors. If you have a unique door design in mind, you can share the detailed design drawing with us. Our experienced engineers will carefully analyze it and offer well – thought – out suggestions. Additionally, if you are in the process of conceptualizing a new project related to shutter doors, our team can provide you with professional insights based on our industry knowledge and experience.

In essence, rolling shutter doors are produced using specialized rolling shutter making machines. They find extensive applications in various settings such as parking areas, residential homes, commercial shop fronts, and garages. These doors are characterized by their strength and ability to safeguard properties effectively. They act as a reliable barrier against theft and fire hazards. The strength of rolling shutter doors can be significantly improved by incorporating an appropriate amount of steel in their construction, ensuring enhanced durability and security.

Beenew Machinery stands out with its ability to design an extensive array of rolling shutter machines dedicated to manufacturing roll – up shutter slats. Our product portfolio encompasses a diverse spectrum of shutters, including straightforward security rolling shutters, those specifically crafted for storm protection, uniquely custom – designed roller shutters, highly effective fire – proof rolling fire shutters, ultra – fast roll – up shutters, and sectional door rolling shutters.

In addition, we offer an enhanced feature by integrating a servo motor and a no – stop tracking cutting system into the Rolling Shutters Making Machine. This results in an impressive operating speed of 25 to 30 meters per minute. All the crucial operational data is precisely set up in the PLC computer program, providing you with the flexibility to select either the Delta or Mitsubishi system according to your preferences.

Rolling Shutter Machine

Rolling steel shutter doors have become a common choice for various commercial and industrial spaces such as warehouses, garages, and shops. The primary reason for their widespread use is their remarkable strength. These doors are constructed to withstand significant force, which makes them an effective barrier against unauthorized access and potential damage, thus offering proper safety and protection for the properties they safeguard.

The operation of these rolling steel shutter doors is designed to be fully automatic, and it can be efficiently managed by just one person. This automation not only enhances convenience but also improves operational efficiency.

All of our roll – up shutter doors are equipped with state – of – the – art automatic drive technology. This technology ensures smooth and seamless operation. However, we understand that power failures can occur unexpectedly. Therefore, we have incorporated a manual override feature into the design. In case of a power outage, users can still open or close the doors manually.

In terms of performance, our roll – up shutter doors are dense, which contributes to their strength and insulation properties. They operate quietly, generating a low decibel level. This noiseless operation is beneficial in environments where noise pollution needs to be minimized, and it also reflects the high – quality and reliability of our products.

Shutter Patti Machine

Actually, Beenew Machinery makes all kinds of roll – forming machines for steel personnel roller shutter doors. Steel roller shutters are very flexible and have many choices, so we can design them for what our customers want.

Also, galvanized steel roller shutter doors can be used in many places. They’re great for backyards, shops, and factories. We have lots of styles of roll – forming machines for shutter bars. We’ve made many 2 – in – 1 machines that combine two profiles with automatic feeding.

The shutter slat width is 35mm – 65mm for windows and small doors, and 50mm – 150mm for doors and garages. The base slat materials are PPGI, GI, and SS, and POLY + ISO is for foaming.

Grill Rolling Shutter Making Machine

Rolling grill shutters offer an aesthetically pleasing grille solution for high – security internal commercial outlets. The closely – wound coils and alternative link patterns enable significant transmission of light and provide an unobstructed view from the exterior. To enhance security, brick – bond or in – line styles, along with solid slats, can be incorporated.

Window security grilles, which are a type of rolling grill shutters, are highly popular as windows are often the first point of entry targeted by intruders. We are capable of manufacturing grill rolling shutter machines with diverse designs based on customers’ specific requirements.

Rolling Shutter Door Bottom Plate Roll Forming Machine

Bottom plates, which can also be referred to as lock plates, are essential components that are installed at the base of rolling shutters. In the market, there is a variety of models of bottom plates to choose from. However, the T – Block bottom has gained the most popularity among users. This could be due to its unique design, functionality, or compatibility with different types of rolling shutter systems.

The Bottom Making Machine is a specialized piece of equipment. It is engineered with precision to manufacture high – quality bottoms for rolling shutter systems. This machine ensures that the bottom plates produced meet strict quality standards, in terms of durability, strength, and fit.

The bottom plate serves a crucial purpose in the overall performance of the rolling shutter. Its main function is to act as a barrier against wind – driven rain. During inclement weather, strong winds can carry rainwater at an angle, and without a proper bottom plate, the rain could easily seep under the shutter and cause damage to the interior space protected by the shutter. By installing a well – designed bottom plate, the risk of water infiltration is significantly reduced.

Australian Rolling Shutter Door Machine

The Australia steel roller doors are characterized by several notable features. They are easy to install, operate with low noise, can be manually lifted, and come in beautiful colors with a smooth and horizontal embossed design.

Roll Doors Australia offer enhanced durability. Their installation process is straightforward, which enables rapid construction and saves the overall construction period.

The stainless – steel Australian rolling shutters not only create an appealing landscape effect and provide good ventilation but also offer strong isolation and anti – theft capabilities.

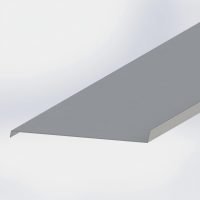

Aluminum Window Sill Roll Forming Machine

An aluminum window sill serves to prevent moisture, leakage, splashes, and staining by diverting rainwater away from the window area. This system consists of a specially – crafted aluminum drip. It features a distinct rounded edge that is created through a roll – forming process using a roll – forming machine. Window sills are engineered to be installed in conjunction with windows at the bottom part of the window opening.

Product Overview

Material: Galvanized Coil

Material Thickness: Ranging from 0.8 to 1.2 mm

Main roll forming machine Power: 7.5 KW

Forming Speed: Between 4 and 7 m/min

Dimension: 7×0.8×0.8 m (Length × Width × Height)

Weight: Approximately 4 – 5 T

Main Components

The machine is composed of the following key parts:

Manual Decoiler: Used for unwinding the galvanized coil.

Roll Forming System: Responsible for shaping the material into the desired form.

Hydraulic cutter: Cuts the formed material to the required length.

Control system: Manages and regulates the overall operation of the machine.

Output table: For receiving and temporarily storing the finished products.

Working Process

Un coiler — Feeding — Roll Forming — Cutting — Product rack

Roller Shutter Door Roll Forming Machine

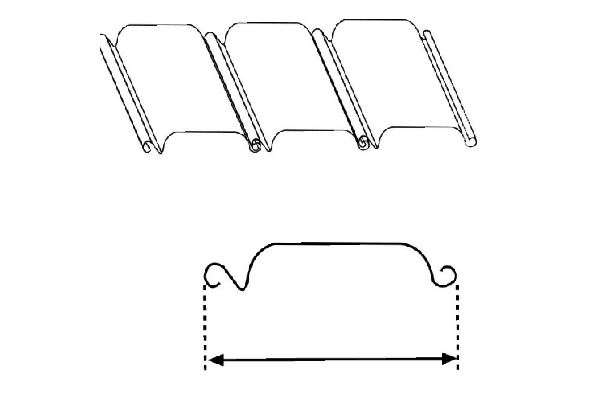

Rolling shutter doors are a kind of door or window shutter made up of multiple horizontal slats. To open the door, you raise it, and to close it, you lower it. Fast rolling shutters are swift and space – conserving, making them suitable for a wide range of applications, including in different structural settings and industrial areas. These doors can be opened either manually or by a motor. Some roller shutters, like the PU rolling shutter, can be used as an insulating solution, protecting against hail damage and enduring strong winds.

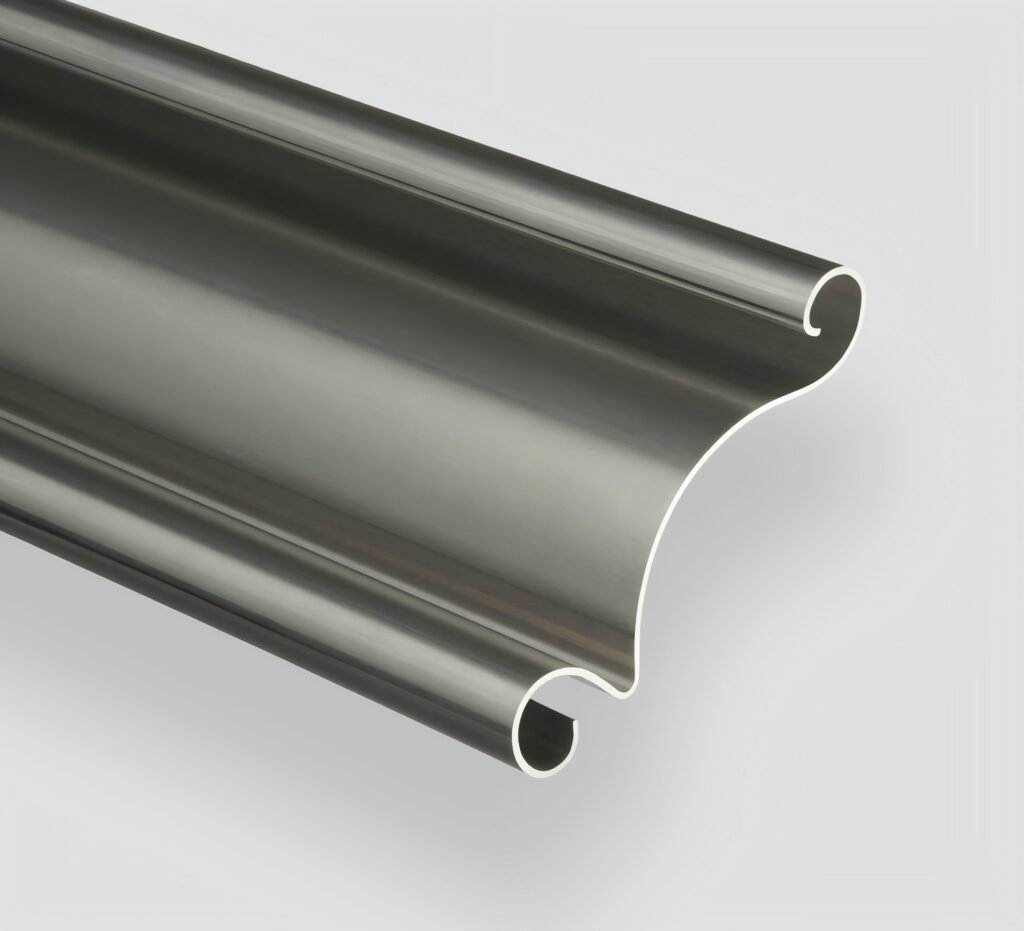

The single – layer slat has an S – shaped design and is produced from steel strips using a roll – forming machine. It features a male joint on one side and a female joint on the other, which allows all the slats to be joined together to create a door or window shutter.

This type of shutter is commonly used for garage and store doors. Manufacturing single – layer shutter slats takes less than two months. With approximately 10 to 15 roller stands, the operation and production of the shutters are quick and hassle – free.

Moreover, installing the shutter is extremely straightforward, and repair services are easy to access. Single – layer shutter slats come in numerous patterns based on usage and customer needs. The finished slats have a width ranging from 40 mm to 200 mm and a thickness of 0.5 to 1.5 mm. As a result, you can envision that there are countless variations of single – layer shutters that can all be manufactured by the roll – forming machine.

PU Foamed Shutter Machine

Fabrication of Polyurethane Shutter Slats

To fabricate polyurethane shutter slats, a complete production line is required, which includes a roll – forming machine, a PU foam machine, a furnace tunnel, an output table, and other components. Roll – forming machines capable of manufacturing high – quality PU shutters should be equipped with more than 30 stand rollers and feature a proper roller design.

Beenew Machinery has over 28 years of experience in this field. This extensive experience allows us to guarantee both the quality of our products and on – time delivery for both global and domestic customers. Currently, our workshop can produce more than 15 sets of a complete line of polyurethane door shutters each month.

Advantages of Pu Foamed Door and Window Shutters

When the PU foamed shutters are rolled up or down, they produce less noise and operate more silently. This means that there is less wear and tear on the joint parts of the shutters each day, resulting in a longer service life. Additionally, in crowded areas, these shutters are more user – friendly and considerate.

Polyurethane shutter doors and windows are excellent sound absorbers. Once the shutters are rolled down, most of the street noise is absorbed by the foam inside the shutters, creating a quieter indoor environment.

The density of the foam in the shutters helps to save energy in the area. Moreover, the shutters are fire – resistant. Therefore, they are highly recommended for main doors and windows as they can make rooms safer and more economical. In conclusion, PU foamed shutters can be regarded as the best choice for doors and windows.

Shutter Machine

These machines vary significantly in terms of quality and speed. Depending on the type of rolling shutters, different machinery should be employed.

Some machines, known as roll – forming machines, process steel coils. They gradually shape the steel through a series of steps and finally cut it into the required sizes.

To install a rolling shutter machine, an area approximately 15 meters in length and 5 meters in width is needed, along with a three – phase power supply.

There are two types of roll – forming machines for making rolling shutter strips:

Gearbox rolling shutter machine

Chain rolling shutter machine

Some rolling shutter machines operate with a gearbox, while others use a chain. The chain – type machine is more cost – effective and can form steel with a maximum thickness of 1.25 mm. If you plan to use steel rolls thicker than 1.25 mm, you must choose the gearbox – type machine. Although this type is more expensive, it offers excellent quality and high – speed performance.

Related Products

Request A Quote

If you have any questions or require more detailed information about our roll forming solutions, please contact us by clicking on the link below.

Our product specialists will be in touch with you shortly to discuss your requirements!