Strut Channel Roll Forming Machine

Strut Channel Roll Forming Machine

Strut Channel Roll Forming Machine

Automated production systems specialized for manufacturing high-precision photovoltaic mounting brackets. Utilizing roll forming technology, these machines efficiently produce structural channels for utility-scale solar farms and distributed PV installations, ensuring dimensional accuracy (±0.5mm) in galvanized/G300 steel profiles. Ideal for rapid fabrication of ground-mount rails, rooftop supports, and tracking system components.

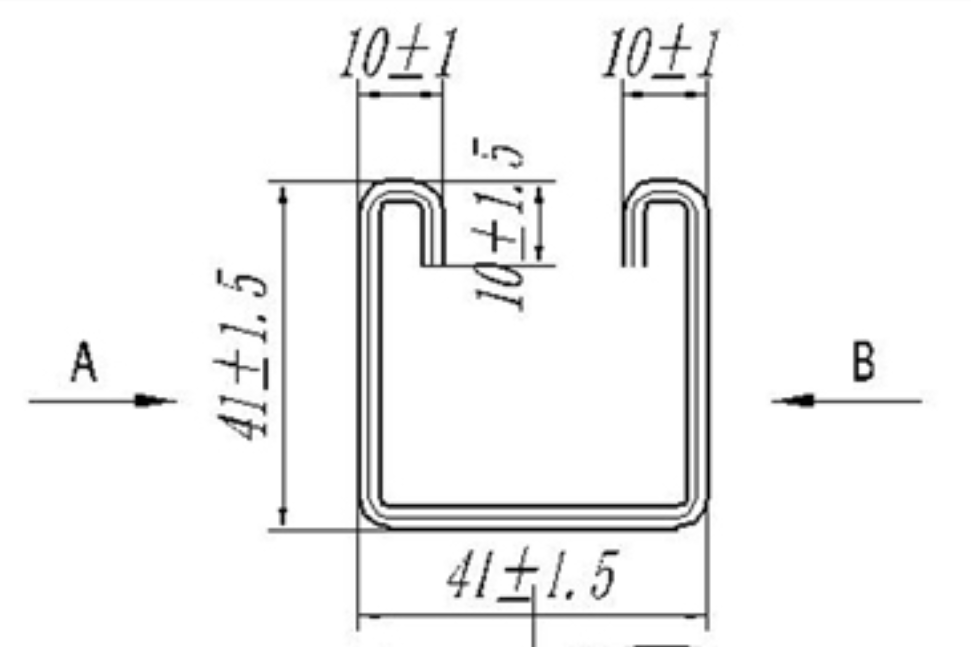

Profile drawing

Uni-Strut Channel Roll Forming Machine Main Information

Strut Channel Size: 41mm*21mm & 41mm*41mm;

Strut Channel Thickness: 1.5mm-2.5mm;

Materials: Galvanized Coil , Painted Steel;

Forming Stations: 24 stations

Description of Strut Roll Forming Machine

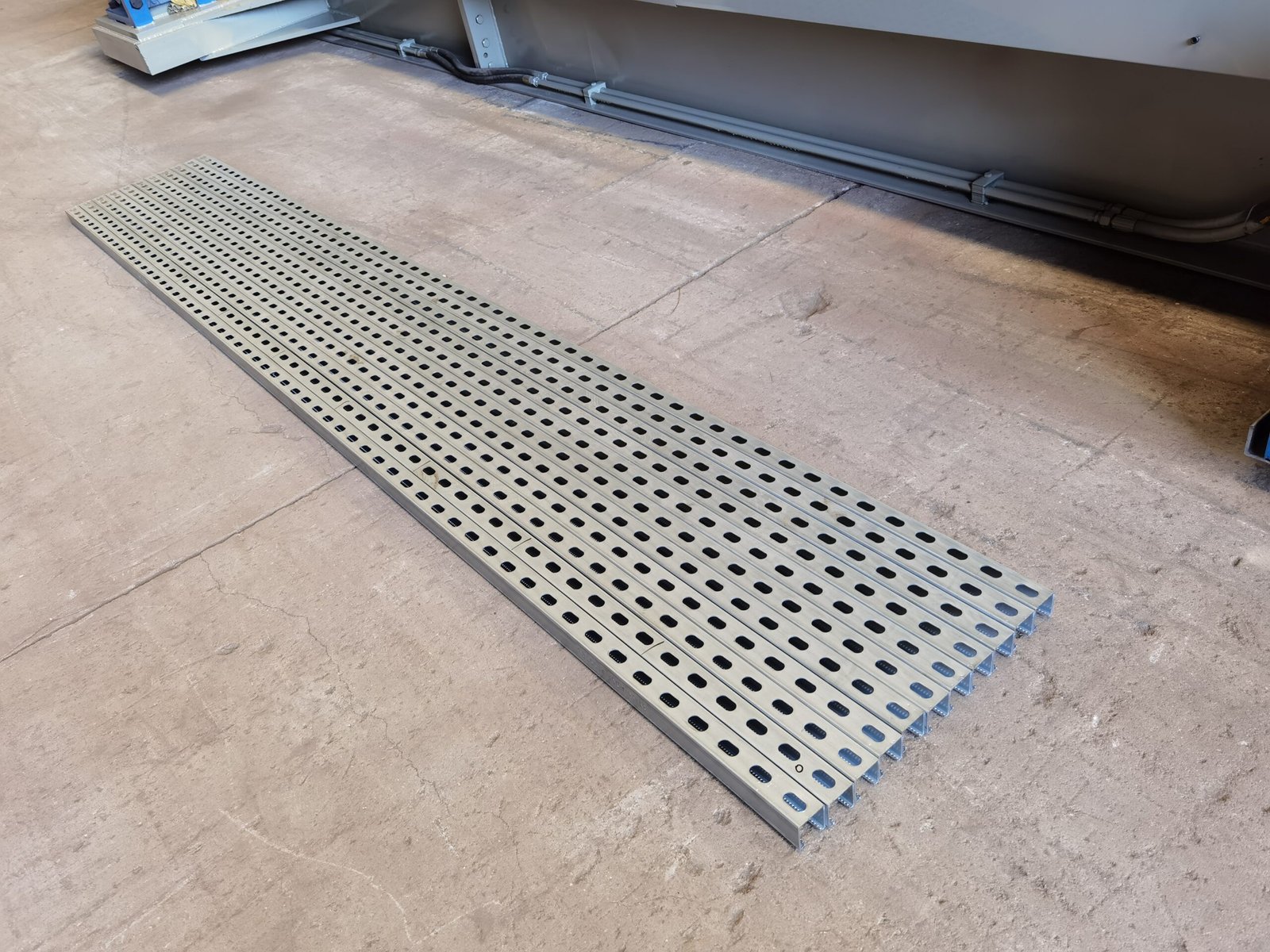

The most common sizes of solar strut sections are U41*21 and U41*41. This machine can automatically change the shape between the two sizes, which saves labor and time costs.

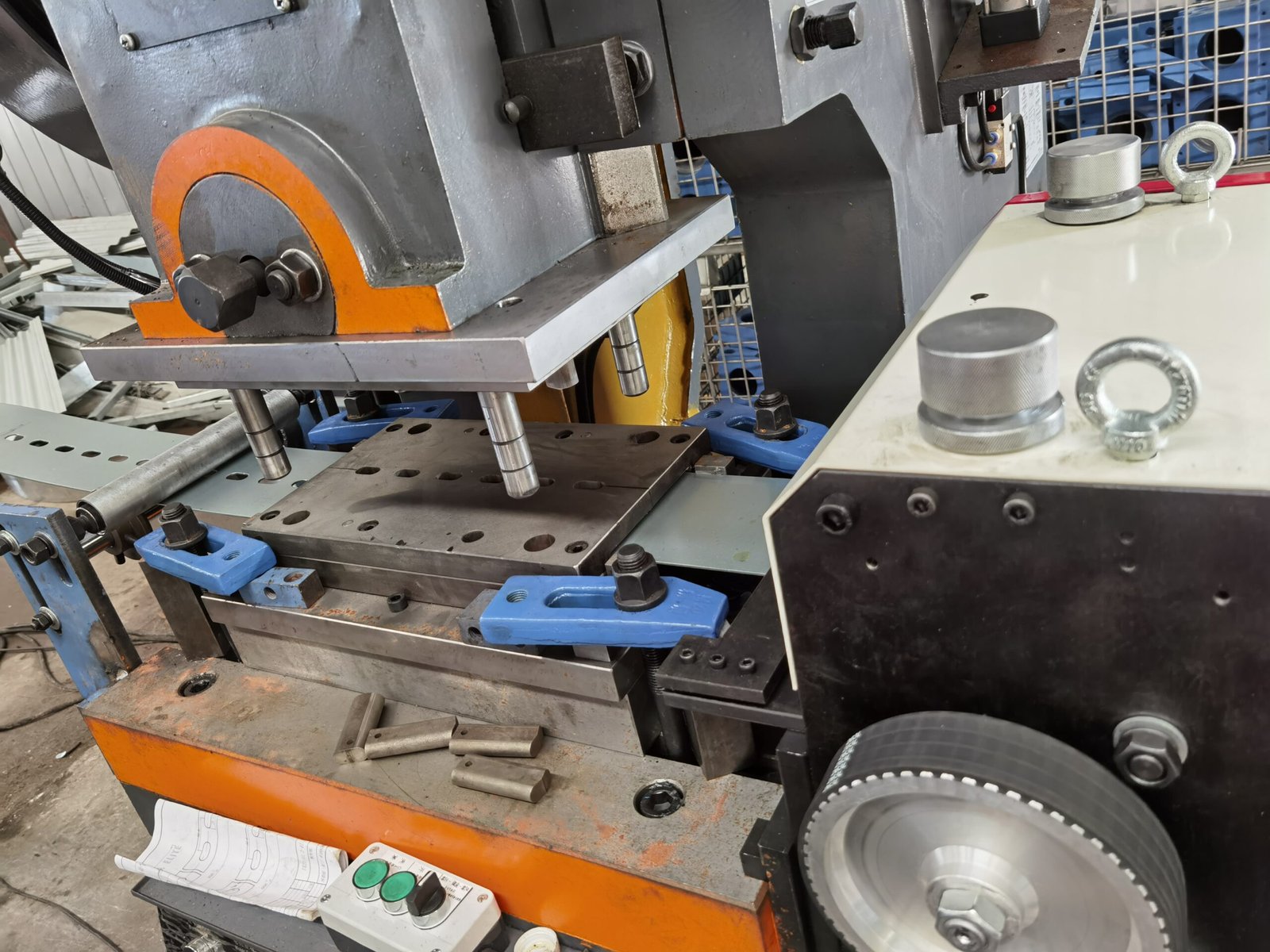

It is equipped with servo motor to make sure the machine can run at high speed and at the same time, the machine shear and punch lengths are accurately positioned. The precision transmission system can assure low failure rate, and easy to operate, the machine does not need frequent adjustment after debugging;

All the parts of the machine have been processed by high precision machining and special treatment of the surface, coupled with the fully automatic numerical control system, which makes the size of the bracket produced is very accurate and the quality of molding is high;

Another feature of the solar bracket is that it needs to be stamped with a large number of holes. Our equipment is equipped with CNC punching machine, which makes the stamped holes precise and can avoid the problem of inaccurate holes when installing PV mounts.

Workflow

-Uncoiler A uncoiler is used to load and uncoil the steel coil to make it easy to be fed into the forming machine.

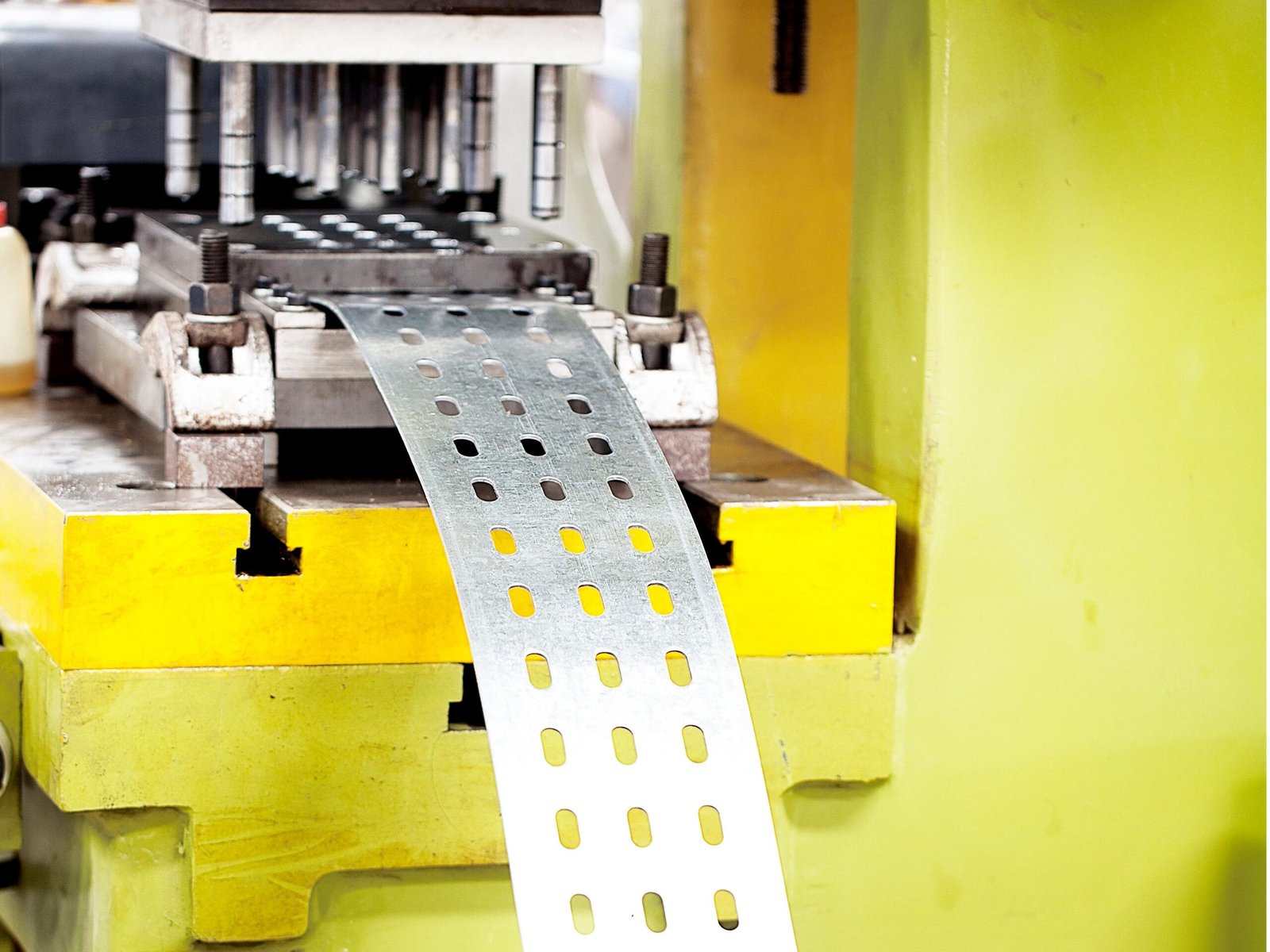

-Punching CNC Punching machine is equipped to punch large amount of holes.

-Roll Forming The whole machine set consists of 24 stations of rollers which can bend and shape the steel coils into a perfect U shape. All rollers are fine processed or special deal with if material is of high quality and tension.

-Post Cutting A flying or tracing cutter is equipped to cut after the U channel is formed. This tracing cutter can cut without stop the machine which can speed up the forming process and increase production.

-Product Rack After all above procedures, U channel comes to the product racks then be packed. If clients need a fully automatic production, automatic stacker can makes packing more easily and efficiently.

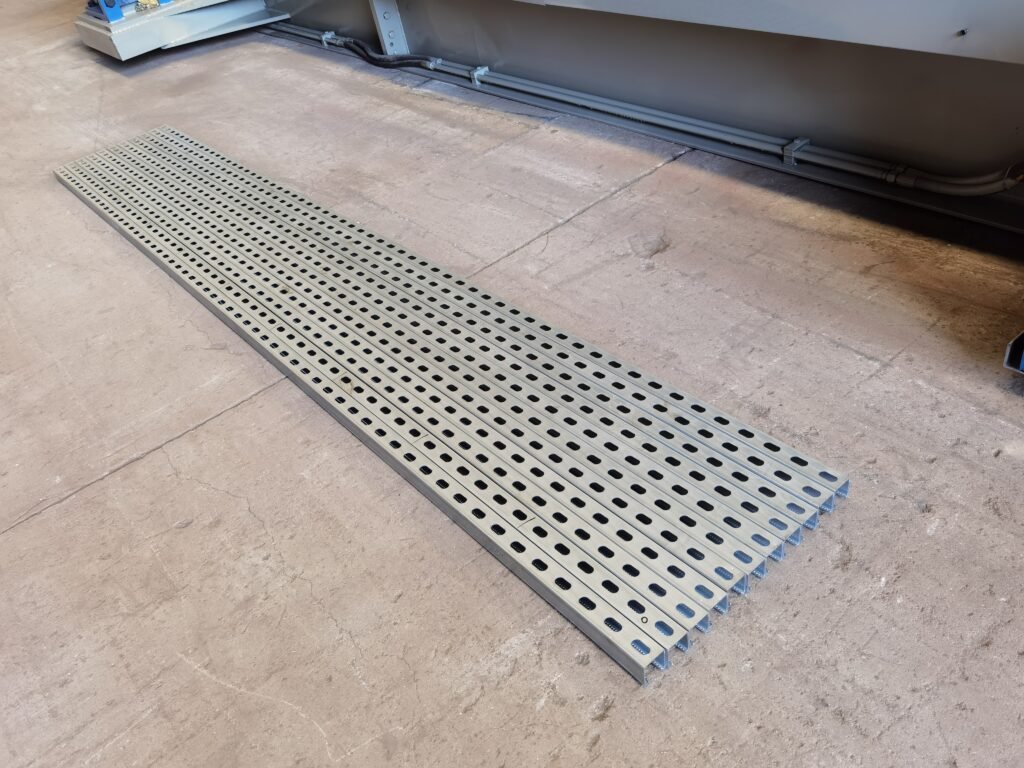

Product samples

Why Choose Us

1).Different customers have different requirements, and we have a professional and experienced technical team that can realize customized services according to different needs.

2).We have nearly 28 years of experience in the cold forming machine industry, and our workers are all experienced, so the quality of our products is stable.

3).We have a complete after-sales system that can quickly respond to customers’ after-sales needs, and our after-sales personnel have rich overseas after-sales experience.

Item | Parameters |

Material | 1.5-2.5mm galvanized steel, color steel, aluminum-magnesium-manganese plate |

Material Feeding Width | 132.5mm |

Driving Motor | 22 KW |

Hydraulic Motor | 5.5KW *2 |

Machine Frame | H450 Steel Base, 18mm thickness wall plate |

Shafts Diameter | Φ75mm |

Roller Material | Cr12 steel,fine-finished,heat treated and outer surface planting |

Forming Station | 24 stations |

Forming Speed | 18-23M/Min |

Related Products

Request A Quote

If you have any questions or require more detailed information about our roll forming solutions, please contact us by clicking on the link below.

Our product specialists will be in touch with you shortly to discuss your requirements!