Glazed Tile Roll Forming Machine

Glazed Tile Roll Forming Machine

Glazed Tile Roll Forming Machine

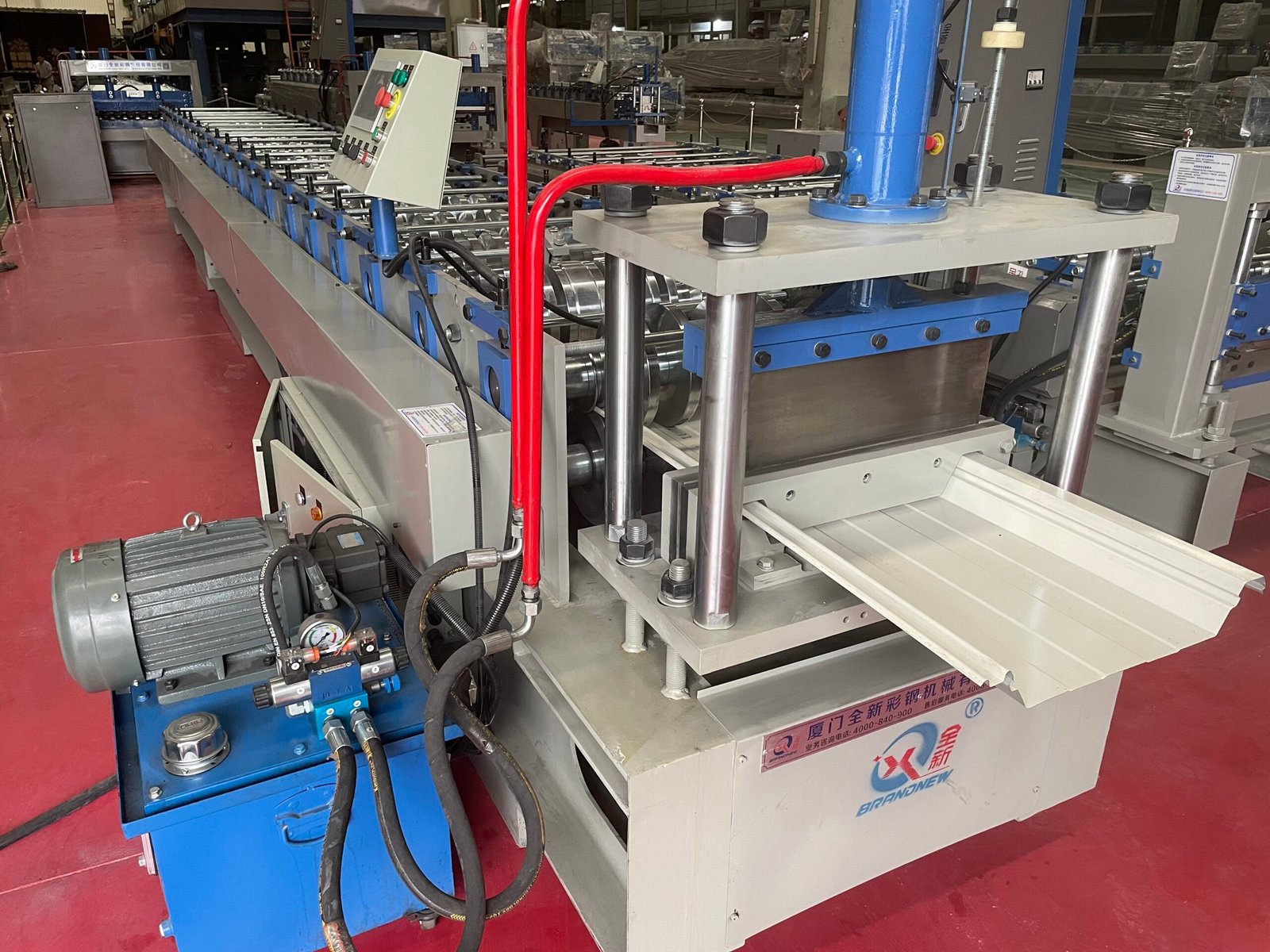

We Xiamen Beenew Machinery is one of the professional roof sheet roll forming machine factories in China. likewise, we can supply different kinds of roll forming machines for different Glazed Tile Profile Sheets. The metal tile roof is lighter than concrete or clay tile roof, more durable than an asphalt shingle roof, and easier to handle than long-run corrugate sheets.

Advantage of Metal Roofing Tile

1)ARCHITECTURALLY DESIGN

2)DURABILITY

3)PERFORMANCE

4)SUSTAINABILITY

5)COST COMPETITIVE

If you have your design, show us your design drawing, a good suggestion can be given out by our engineer. if you have any idea about your new project, some professional ideas can be getting from us.

By automating the process of feeding, shaping, and cutting metal coils into precise profiles, our glazed tile roll forming machines deliver tiles with enhanced weather resistance, fireproofing, and longevity compared to traditional materials.

This glazed tile roll forming machine integrates advanced hydraulic cutting systems, programmable logic controllers (PLC), and automated decoiling mechanisms to ensure flawless consistency, high-speed output, and minimal waste. Its precision tooling replicates intricate textures and glossy finishes, achieving the authentic charm of glazed tiles without compromising metal’s lightweight, low-maintenance advantages.

The glazed tile roll forming machine empowers manufacturers to offer versatile styles—from rustic terracotta to sleek modern finishes—blending timeless aesthetics with cutting-edge performance. As industries prioritize efficiency and eco-friendly solutions, this machine stands pivotal in reshaping roofing markets worldwide.

1)Summary of metal roofing materials

Material: Galvanized Coil, Color steel coil

Material Thickness:0.4-0.6mm

Main roll forming machine Power:7.5KW

Forming speed: 3-4m/min

2) Main Components

5 Tons Manual Decoiler

Manual pre-shearing

Feeding Guide

Roll Forming System

Hydraulic Cutting unit

Control system

Output table

Each part technical parameter

1.Manual decoiler

Loading capacity 5T

Steel coil I.D. φ480-φ530mm

Steel coil O.D. max. φ1300mm

Max coil width 1219mm

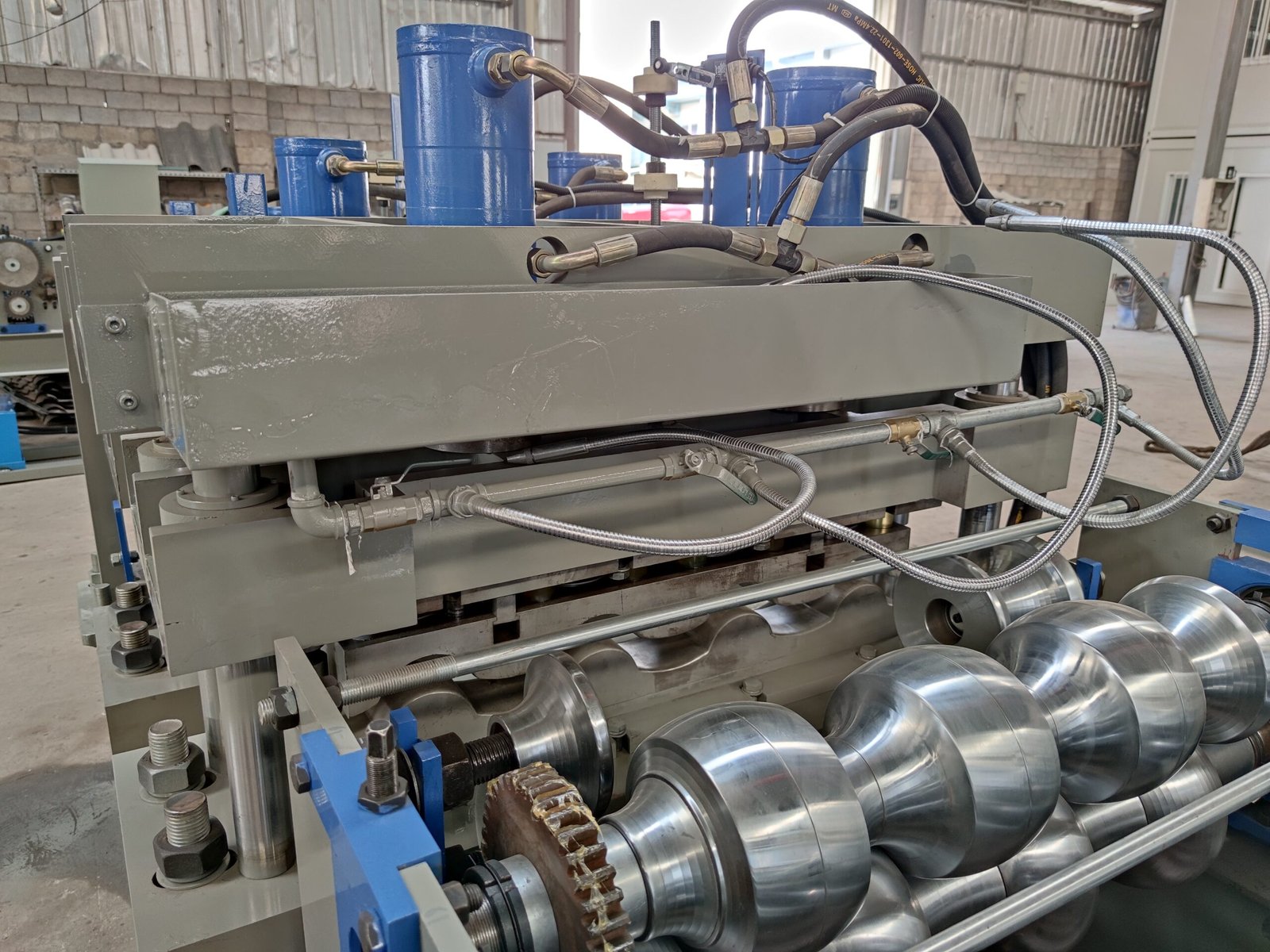

2.Roll Forming Machine

Roller groups 14 roller stations

Roller material 45# Steel, chrome coated with heat treatment, HRC58-62°

Roller shaft dia. Φ75mm

Shaft material 45# Steel with quenching and tempering

Motor 7.5KW

Transmission way Chain

Machine frame bod H-beam Welded , Stress-Relieving

Roller stand Wall panel

3.Hydraulic cutting unit

Cutting way Hydraulic stop cutting

Hydraulic pump motor 5.5kw

Cutting die Cr12 with quenching treatment

4.Electricity control cabinet

Frequency inverter DELTA

PLC DELTA

Screen touch screen DELTA

Low voltage Schneider

Power supply 380V/50HZ/3P (or customized)

Metal roof tiles offer unmatched durability, low maintenance, and climate-resistant longevity, often enhanced with mold- and moss-resistant coatings. Lighter than concrete or clay, more durable than asphalt, and easier to install than corrugated sheets, they provide a cost-effective, long-term roofing solution.

The glazed tile roll forming machine elevates metal roofing design by shaping sheets into profiles that authentically mimic wood, slate, or glazed ceramic tiles. This technology combines the timeless elegance of traditional materials with metal’s lightweight, weatherproof, and fire-resistant benefits. Advanced finishes eliminate the “metallic” compromise, delivering realistic textures and glossy, vibrant colors.

Ideal for modern demands, metal roofs crafted by glazed tile roll forming machines balance aesthetic versatility with eco-friendly performance. Homeowners enjoy a wide variety of styles and colors, from classic terracotta to contemporary hues, ensuring enduring curb appeal and value.

After-Sales Service for Glazed Tile Roll Forming Machine

1)Warranty Coverage

A comprehensive 2 years warranty is provided, complemented by lifetime technical support.

2)Delivery Commitment

Machines are delivered within 25-40 working days after confirming receipt of the deposit payment.

3)Service Guarantee

24 months free maintenance service for all components.

Lifetime paid service available post-warranty, ensuring ongoing assistance for repairs, parts replacement, and troubleshooting.

4)Installation & Training Support

On-site installation guidance and in-person training are offered if clients visit our factory for machine inspection.

Our engineers will train your technicians/workers in machine operation, maintenance, and safety protocols.

FAQ

Q: Are you a trading company or a manufacturer?

A: We are a direct manufacturer with a dedicated production team and export-focused service expertise in cold roll forming machinery.

Q: Can the machine produce only one panel profile?

A: No. Our machines are engineered for multi-profile versatility, supporting wider and dual-layer production capabilities. A single unit can produce 3+ distinct panel profiles with tooling adjustments.

Q: What is the typical lead time for machine production?

A: Standard lead time is 20–45 business days. For urgent orders, we prioritize production to expedite delivery without compromising quality.

Q: How is quality control ensured during manufacturing?

A: Our rigorous QC protocol includes raw material inspection,precision machining of rolls and critical components.

Assembly verification,surface and shaft integrity testing,pre-shipment operational trials and packaging checks.

Q: What if the machine malfunctions?

A:24-month warranty,Free replacement of irreparable parts (customer covers shipping fees).

Post-warranty support: Lifetime technical assistance and negotiated repair solutions.

Q: What differentiates you from competitors?

A: Our strengths include customer-centric service with tailored engineering solutions.

Low-maintenance, user-friendly designs for quick installation and operation.

Value-added guidance to optimize your ROI and product performance.

Q: Can we partner as your international agent?

A: Absolutely! We actively seek collaborations with distributors or agents to sale our roll forming machine.

Machine Description

Roller groups 14 roller stations

Roller material 45# Steel, chrome coated with heat treatment, HRC58-62°

Roller shaft dia. Φ75mm

Shaft material 45# Steel with quenching and tempering

Motor 7.5KW

Transmission way Chain

Machine frame bod H-beam Welded , Stress-Relieving

Roller stand Wall panel

3.Hydraulic cutting unit

Cutting way Hydraulic stop cutting

Hydraulic pump motor 5.5kw

Cutting die Cr12 with quenching treatment

Related Products

Request A Quote

If you have any questions or require more detailed information about our roll forming solutions, please contact us by clicking on the link below.

Our product specialists will be in touch with you shortly to discuss your requirements!