CZ Purlin Roll Forming Machine CZ40040

CZ Purlin Roll Forming Machine CZ40040

CZ Purlin Roll Forming Machine CZ40040

Beenew fully automatic CZ40040 purlin roll forming machine can produce CZ purlins of various sizes and thicknesses for customers, with thicknesses ranging from 2.0mm to 4.0mm. This purlin forming machine is a fast-changing C/Z purlin manufacturing machine that can complete the interchange of CZ plate types within 10 minutes. This is an advanced automated roll forming machine that enables efficient and precise purlin production.

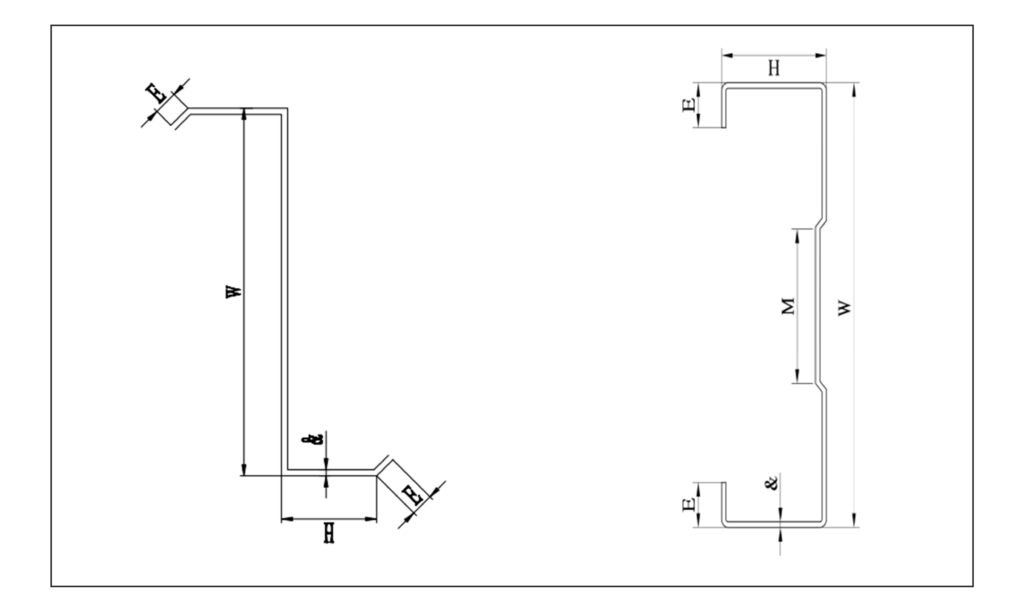

Profile drawing

Main Components Of The CZ40040 Purlin Machine

1.Decoiler

Type:Manual decoiler or hydraulic decoiler

Load capacity:7T

Coil inner diameter:480-580mm

2.Main CZ roll forming machine:

Leveling station: Solid φ105mm (upper 3 and lower 4) rollers plus additional pressure rollers are used to level the steel coils

Roller material: flat wheel Gcr15 bearing steel/slant wheel Cr12 mold steel

Purlin machine main drive: servo motor 45.0KW

Machine spindle: φ100/85mm40Cr round steel quenched and tempered

Blade material: Cr12Mov mold steel wire cut and heat treated

Control system: automatic PLC control with touch panel settings

Purlin size adjustment: continuous adjustment through PLC control and touch panel settings

3. Hydraulic punching and general cutting system:

Punching unit configuration: Four groups (3 double holes + single hole) 14*25

Punching position: Punching on the web side and flange side

Punching type: Supports round holes and slotted holes

General cutting: Handles all C-type and Z-type purlin cutting needs

Machine intelligent control: Cutting length, number of cutting pieces and punching operations are automatically controlled by advanced PLC (Programmable Logic Controller)

4.Overview of other optional systems:

Inkjet printing system: custom printing of company name, corporate logo, product code, etc. on purlin flanges

Pre-cutting mechanism: quick change of steel coils without affecting production flow

Flat plate pre-punching equipment: pre-punching and slotting operations

Automated stacking system: stacking of processed C- and Z-shaped purlins

Additional punching unit: supports additional installation of punching devices

5.Main advantages of the fully automatic CZ purlin interchange machine (CZ40040)

High degree of machine automation: fully automatic purlin size adjustment

Wide range of steel and purlins: raw material types can be galvanized steel, black steel.

Universal cutter: Suitable for all C, Z and U purlin sizes

Quick change: Quick change between C and Z purlin types within 10 minutes

Through shaft design: Reduces uneven height caused by machine spindle breakage

High-strength structure: Made of cold-pressed high-strength steel plate, uniform wall thickness and high compressive strength

High precision: High plate shape accuracy, easy adjustment of length offset and purlin punch position

Thickness range: Q235 (2.0-4.0mm) / Q345 (2.0-3.5mm)

Product size:

C purlin size: w120-400mm, h60-100mm, e10-30mm

Z purlin width: w140-300mm, h40-80mm, e10-20mm

Item | Parameters |

Driving Motor | 45KW |

Forming Speed | 30m/min |

Roller Material | 45# steel |

Shaft Diameter | φ100/85mm |

Shaft Material | 40Cr round steel quenching and tempering treatment |

Pump Motor | 11.0KW |

Cutting Type | Hydraulic Cutting |

Control System | PLC |

Punching group | Four groups (3 double holes + single hole) 14*25 |

Related Products

Request A Quote

If you have any questions or require more detailed information about our roll forming solutions, please contact us by clicking on the link below.

Our product specialists will be in touch with you shortly to discuss your requirements!