Corrugated Sheet Making Machine

Corrugated Sheet Making Machine

Australia corrugated sheet making machine

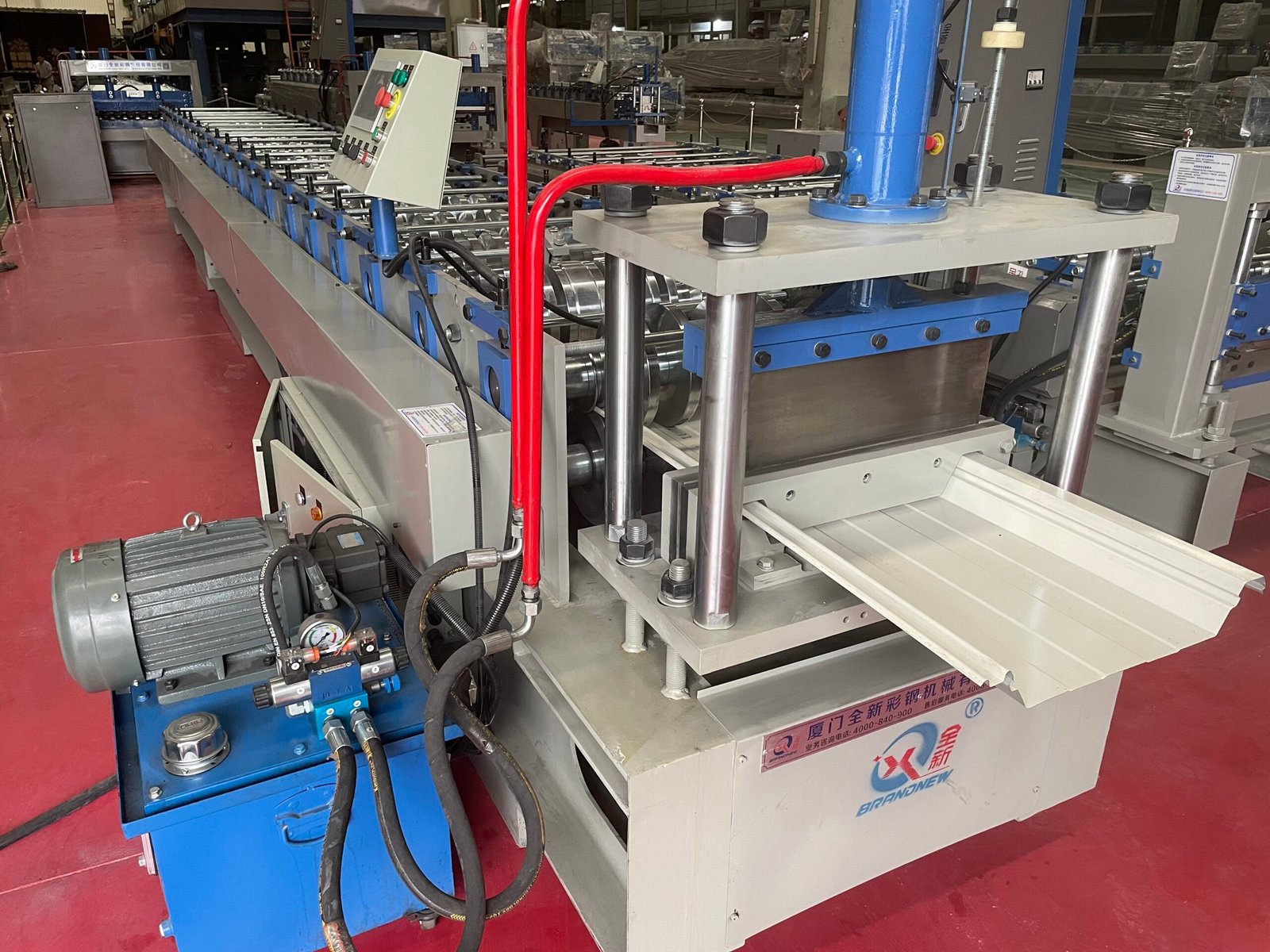

This is a corrugated plate roll forming machine, which is very popular in Australia. Even in China and other countries in the world, this forming machine is very popular with customers. This forming machine uses 0.4mm-0.6mm galvanized coil as raw material. The corrugated plate produced can be used as the roof of the building or as a wall panel, such as villas and factories.

Machine features:

Our roof panel forming machine production line includes unwinder, feeding and leveling device, front shear device, forming main machine, hydraulic back cutting device, finished product rack, hydraulic station and PLC (control system). The production speed of the machine is up to 20m/min.

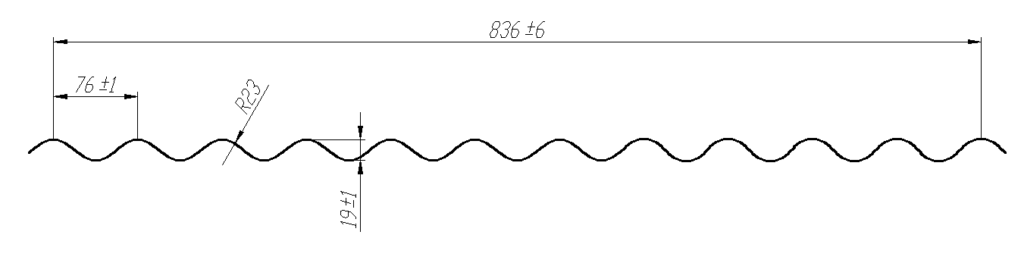

Profile drawing

Material:

1 ) Effective Coil Width: 1219mm

2 ) Suitable Coil Thickness: 0.4-0.6mm

3 ) Suitable Raw Materials: color steel sheet

4) Yield strength of raw material: 235245Mpa

Main Components:

1. Manual decoiler

1)De-coiler: Manual de-coiler

2. Hydraulic pre-cutting system

Used to cut the head and tail of the material

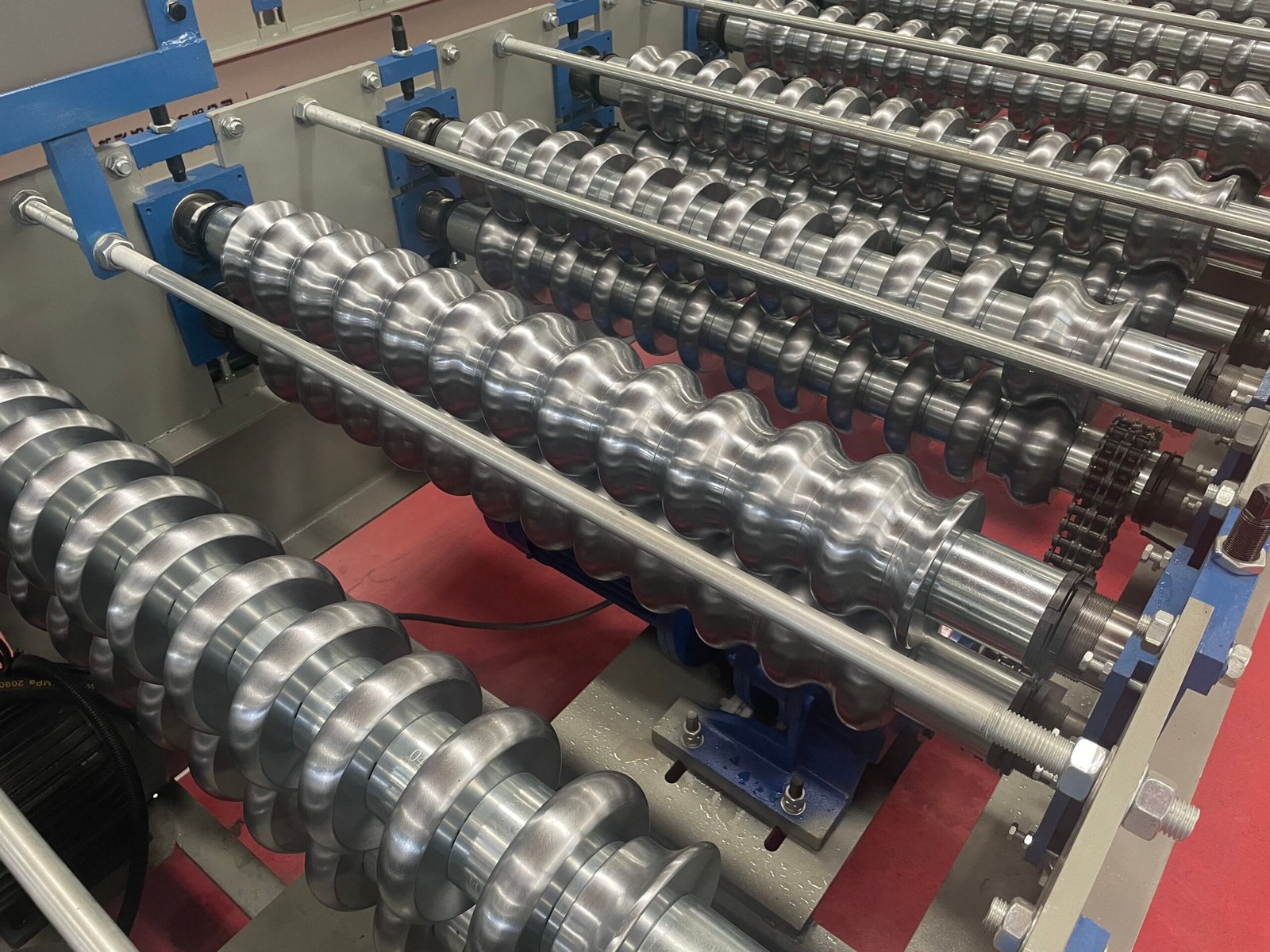

3. Roll Forming Machine:

1)The main frame of the machine is welded separately, and the surface is sandblasted and painted to prevent rust

2)Roller Material is high grade No.45 forged steel

3)The rollers are processed by grinding machines for high precision

4)The roller is processed by precision machine tools, the surface is hard plated, and the service life is long

5)Shaft diameter is 70mm/ 65mm

6)Quantity of profile forming rollers : 16 stations

7)Chain, gear transmission, motor drive, all working actions are automatically controlled by PLC electric control cabinet

8)Main machine motor power: 5.5KW

9)Line working speed (Forming speed): 20m/min (without cut time)

10)Power voltage: 380V/50Hz, 3 phase (can de customized)

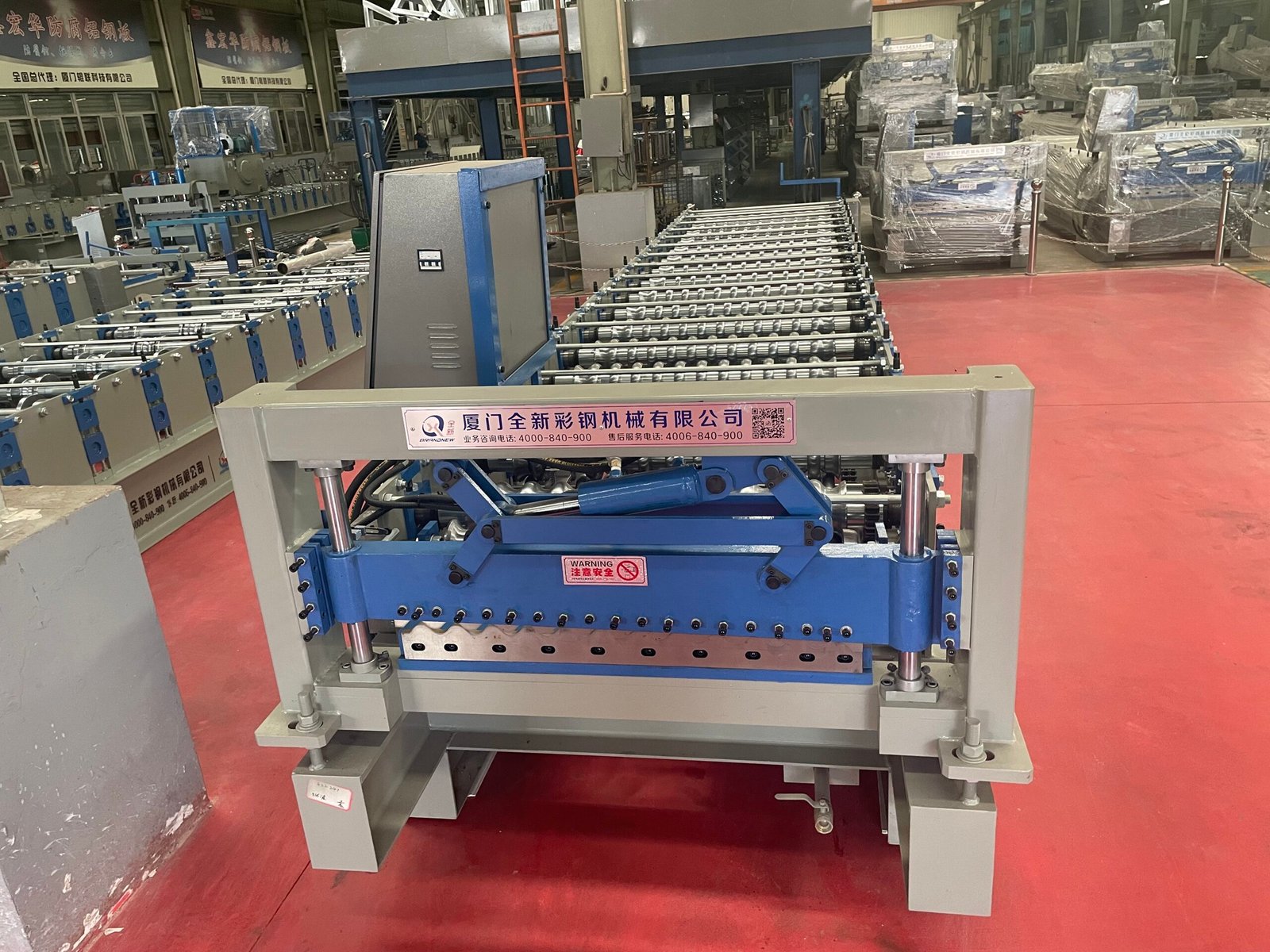

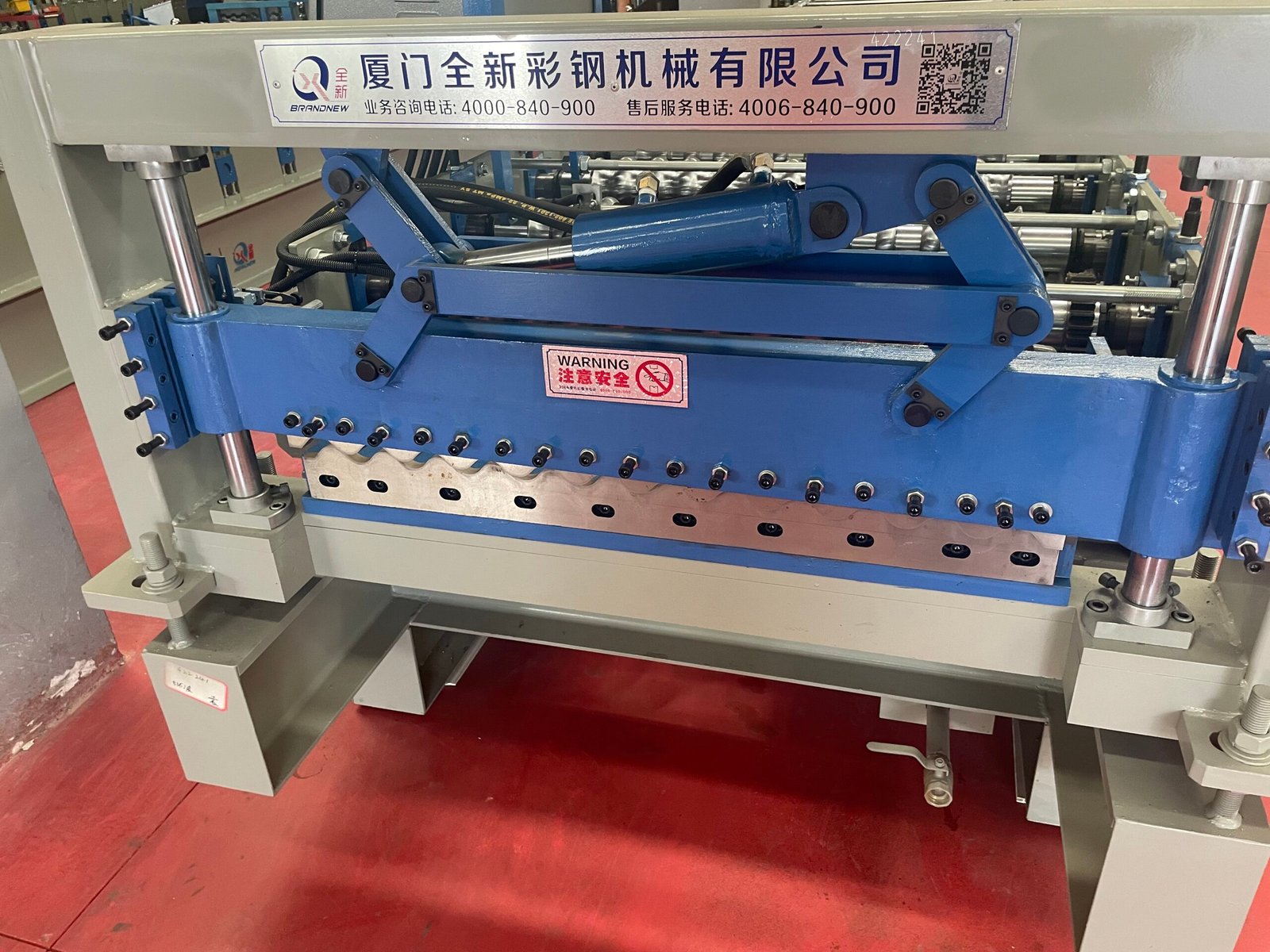

4. Hydraulic Post Cutting

1) Post cutting, Stop when cutting

2) Cutter blade material is Cr12 with quenched treatment

2) Welded frame for good rigidity

4) Cutter frame has been heat treatment to avoid final product deformation,Cutting length tolerance ±2mm

5. Hydraulic station:

1) It powers the hydraulic cutter

2) All hydraulic parts are made of domestic or imported famous brand products

3) Hydraulic station, oil pump power 2.5 KW

6. Product rack

Unpowered, 3 units in total, equipped with rollers on the top for easy movement

Item | Parameters |

Driving Motor | 5.5KW |

Forming Station | 16 |

Roller Material | 45# steel |

Shaft Diameter | 75mm |

Shaft Material | 45# steel |

Pump Motor | 2.2KW |

Cutting Type | Hydraulic Cutting |

Control System | PLC |

Cutting Length Precision | ±2mm |

Related Products

Request A Quote

If you have any questions or require more detailed information about our roll forming solutions, please contact us by clicking on the link below.

Our product specialists will be in touch with you shortly to discuss your requirements!