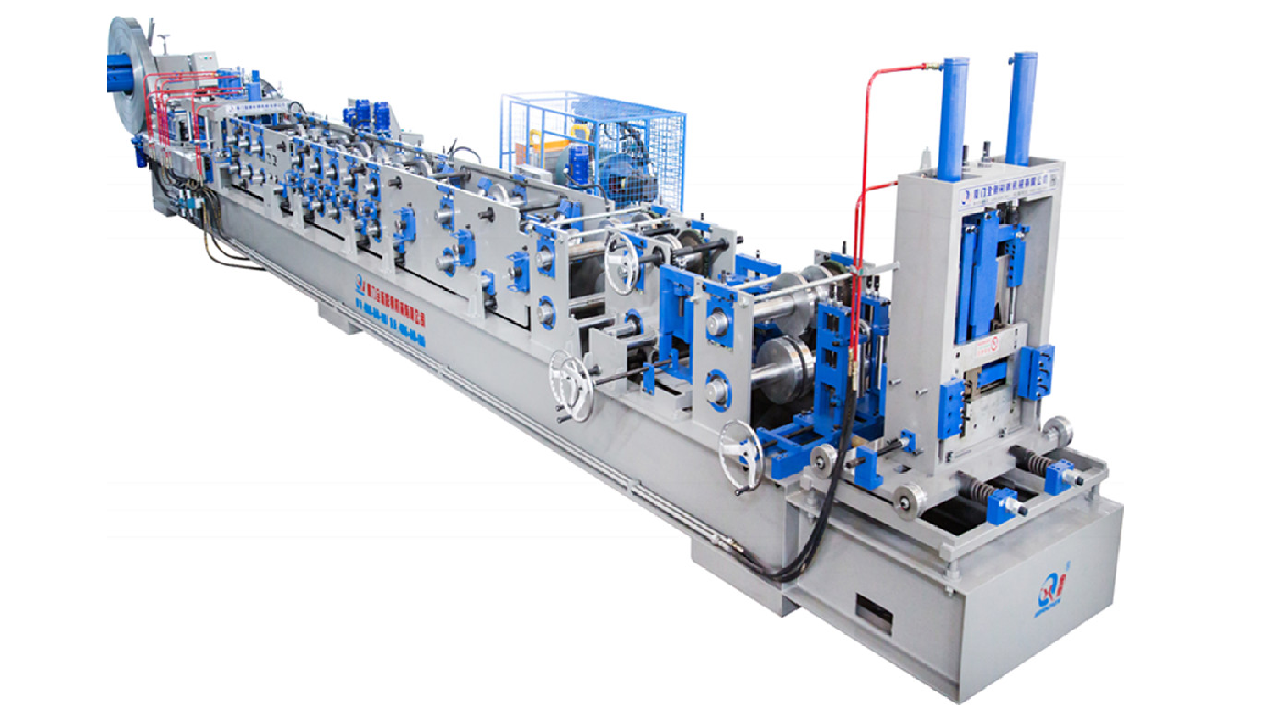

Purlin Roll Forming Machine

Purlin Roll Forming Machine

CZ Purlin Roll Forming Machine

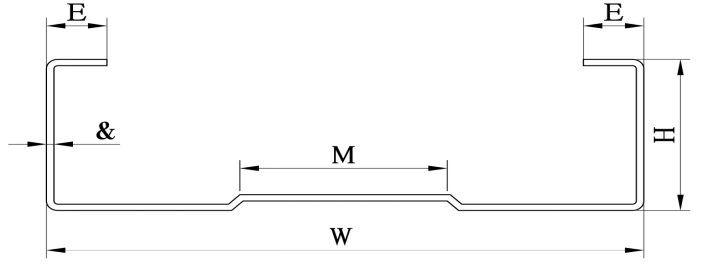

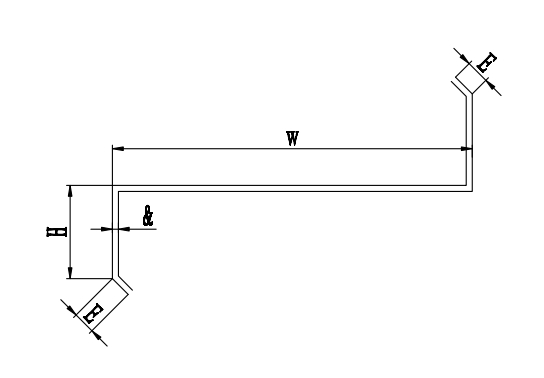

Simply put, cee purlin and z purlin are horizontal beams used as support for building structures. Beenew purlin roll forming machine can produce purlins of different sizes. Roll forming machine for producing C purlin and z purlin, also known as interchangeable size and shape purlin roll forming machine.

The thickness, height and shape of the purlin depends on the span, length and load of the building.

The application scenarios of C & Z purlin are:

1. Steel structure building

2. Warehouse

3. Expansion and renovation projects

4. Agriculture, greenhouse projects

5. Sports stadiums

CU Purlin Roll Forming Machine

Usually, the C purlin machine selected by customers is used to produce C purlin with a thickness of 2.5-3.5mm, but we still have advanced technology to customize C purlin roll forming machine with a thickness of 5mm for customers’ special needs. Thick color steel plate is formed into a solid C purlin.

In fact, this purlin forming machine can produce not only C PURLIN, but also U PURLIN. You can interchange between C-shape and U-shape according to different shape and size requirements.

This is an efficient and stable forming machine that can ensure the production of high-quality purlins that meet strict standards. It is an indispensable production tool in modern construction.

C Purlin Roll Forming Machine

In the steel industry, in order to easily distinguish different steel structure products and simplify the description, products are given a representative name. For example, channel steel profiles without flange reinforcement are usually called C-shaped or U-shaped. In steel structure buildings, purlins used in roofs and secondary structural members such as wall beams are produced by cold roll forming machines in C, Z or U shapes. In addition, G-shaped purlins are also used for the same purpose.

For the production of these purlin products, Beenew Machine has fully automatic purlin forming machines that can produce C, Z, U and G purlins, and can also customize various special purlin roll forming machines according to customer needs.

CZU Purlin Roll Forming Machine

Beenew Machinery has been continuously innovating in the 28 years of manufacturing roll forming machines. The current C-type purlin forming machine can automatically and quickly change the model and size. It can also change the model to produce Z-type steel purlins or U-type purlins.

Therefore, a machine can produce not only C-type purlins, but also U-type, Z-type and even G-type purlins on a roll forming machine, which greatly saves your investment and maximizes the production efficiency and corporate profits of customers.

Purlin Machine

Beenew machinery designs and customizes various purlin roll forming machines for you. Our machines have been used by customers in more than 50 countries around the world. In fact, our purlin roll forming machines include:

cz purlin roll forming machine

c purlin machine

z purlin machine

c and z purlin machine

Material

Galvanized sheet,Tension Grade: Q235MPa-Q550MPa

Thickness: 2.0-5mm

Waist height50-100mm,bottom width100-300m

Decoiler

Hydraulic decoiler, 7T

Coil inner–diameter: 530±30mm

Coil outer-diameter: Max. 1600

Load capacity= Max. 7Ton

Coil Width= Max. 529mm

Roll forming machine

Feeding table with guide,

Gear/Sprocket driving; Dual Leveling

Driving Motor:30KW

Forming Station:20 GROUPS

Roller Material:Gcr15, chrome coated with heat treatment, HRC58-62°

Shaft Diameter:φ90/75mm

Shaft Material:45# steel

Forming speed: Approx.30m/min

Machine frame:450 H-beam, Stress-Relieving

Hydraulic stamping&cutting Device

Cutting type:Hydraulic stop cutting

Hydraulic pump power:11.0KW

Hydraulic pressure:12 Mpa

Hydraulic blade&cutter material:Cr12, quenching process 58-62

Electrical system

PLC Control System

Voltage:380V/50Hz/3P

Rating us

Product Name: PURLIN ROLL FORMING MACHINE

Product Description:

Beenew Machinery have more kinds of purlin roll forming machine,that used to produce C PURLIN、Z PURLIN、U PURLIN.

Brand: Beenew

Currency: $

Availability: InStock

Request A Quote

If you have any questions or require more detailed information about our roll forming solutions, please contact us by clicking on the link below.

Our product specialists will be in touch with you shortly to discuss your requirements!