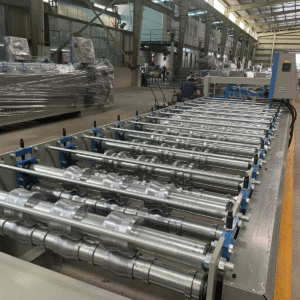

Clip Lock Roofing Sheet Machine

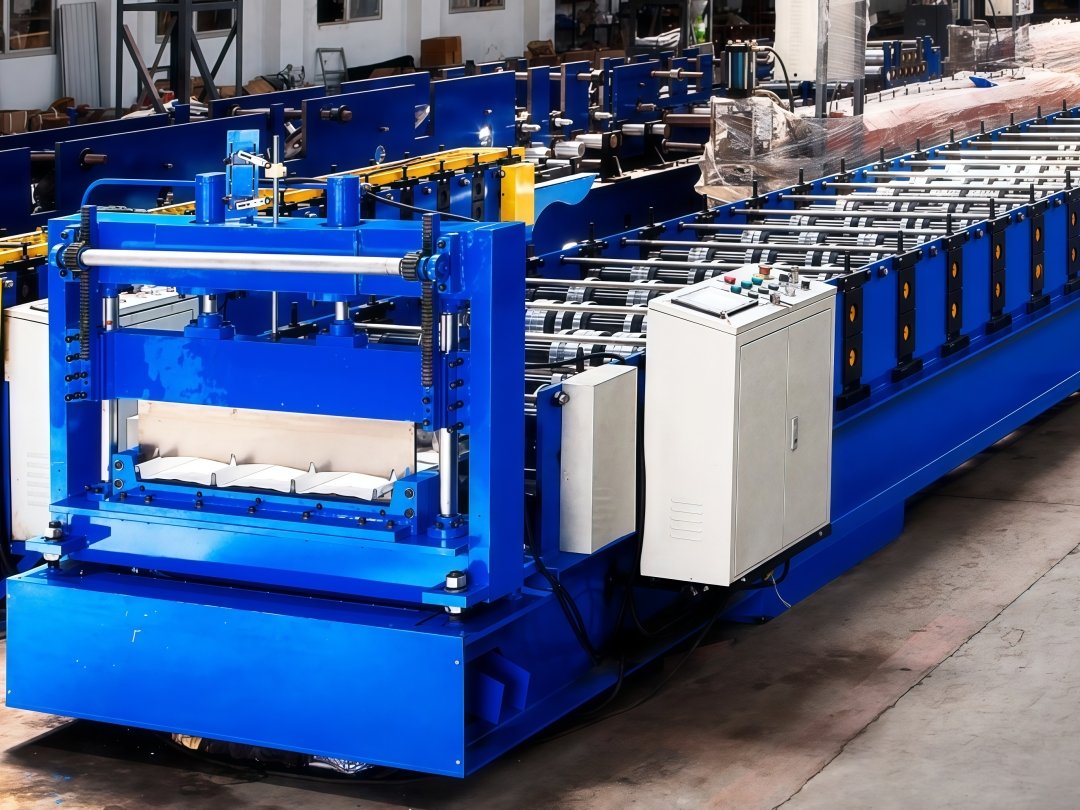

This machine is a precision roll-forming system for manufacturing concealed-fix metal roofing and cladding panels. It forms metal coils into panels featuring a Clip Lock seam

Description

Main Parameters:

Material Thickness:0.3-0.6mm with 550Mpa

Effective Width:710mm

Feeding Width:914mm

Main Motor:7.5KW

Details

This machine produces clip lock roof panels with several practical advantages.

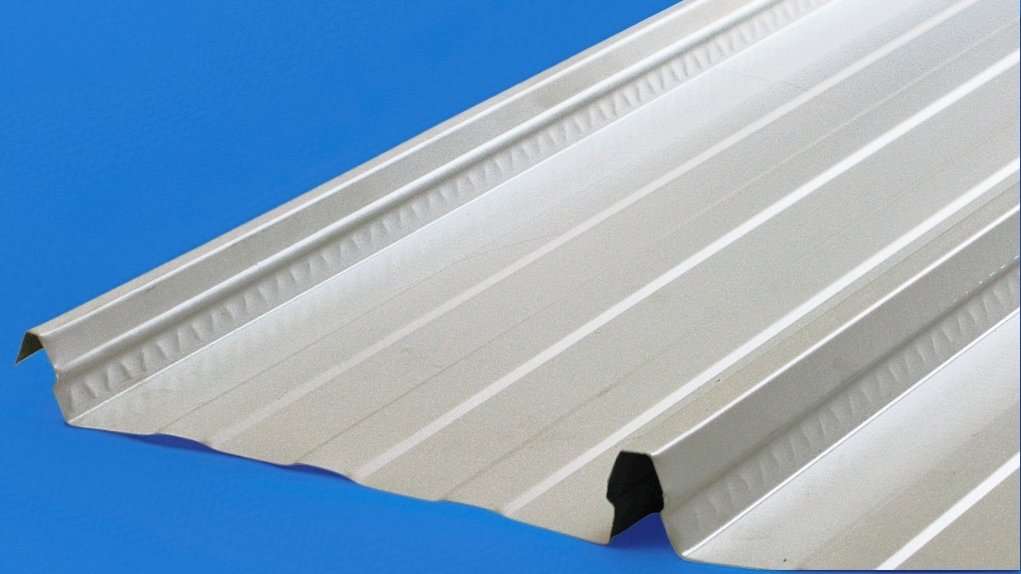

Roofing sheet produced by this machine are sturdy and durable. And they offer excellent waterproofing. They are also aesthetically pleasing, with no exposed screws or nails, and a smooth, flat surface. What’s more, installation of the roofing sheet is exceptionally quick and easy.

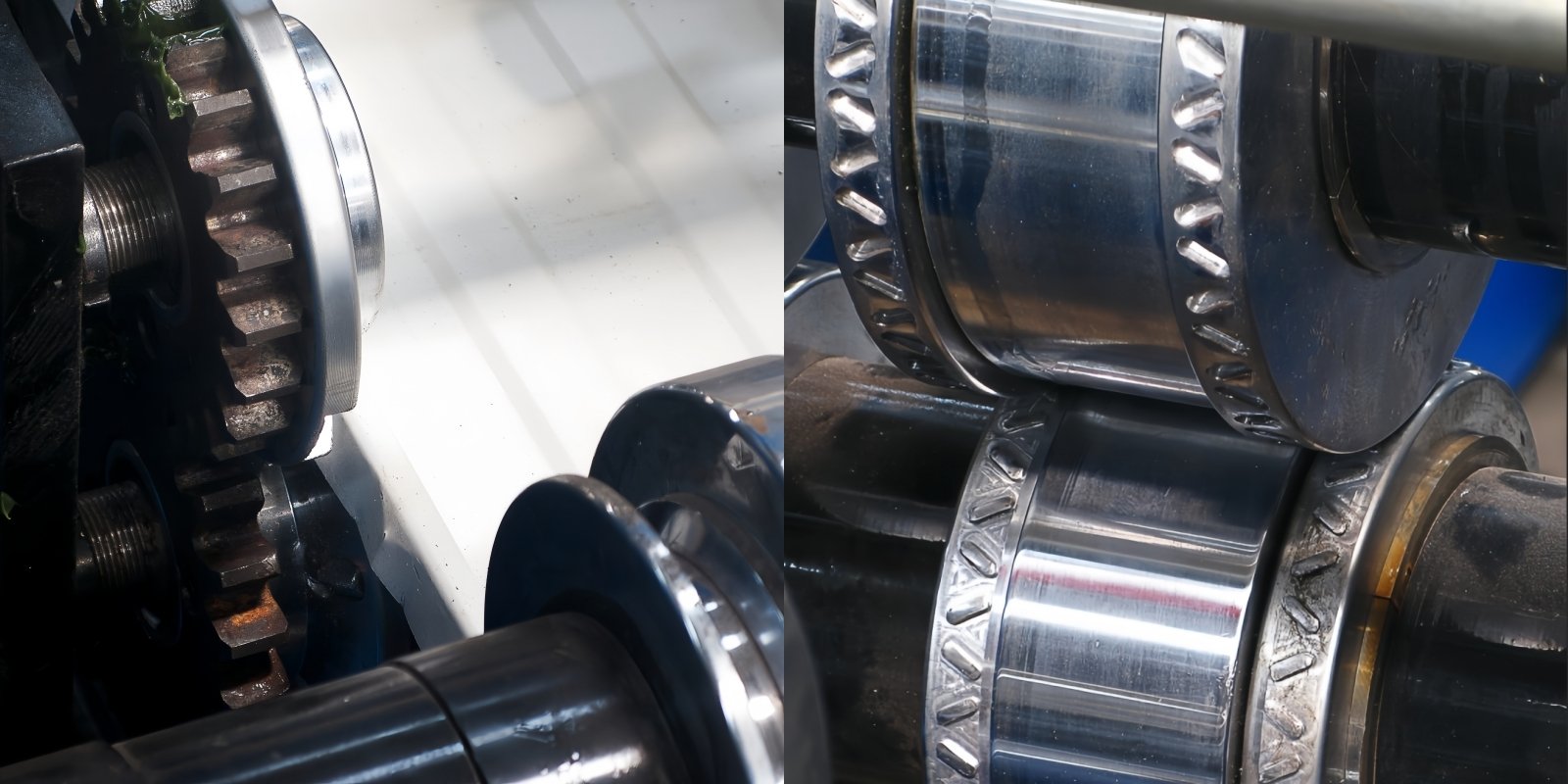

The whole machine is produced strong in order to deal with a high tension aluminum-magnesium-manganese alloy coils. All rollers are made from 40 Cr steel, fine processed, heat treated and then outer face hard chromed. There are totally 26 station of rollers to form. To make roofing more durable, there are rollers to press strength ribs on the side of the clip lock panels.

The machine is operated by a PLC controller and also has a human-machine interface (HMI) for easy operation and inspection by workers.

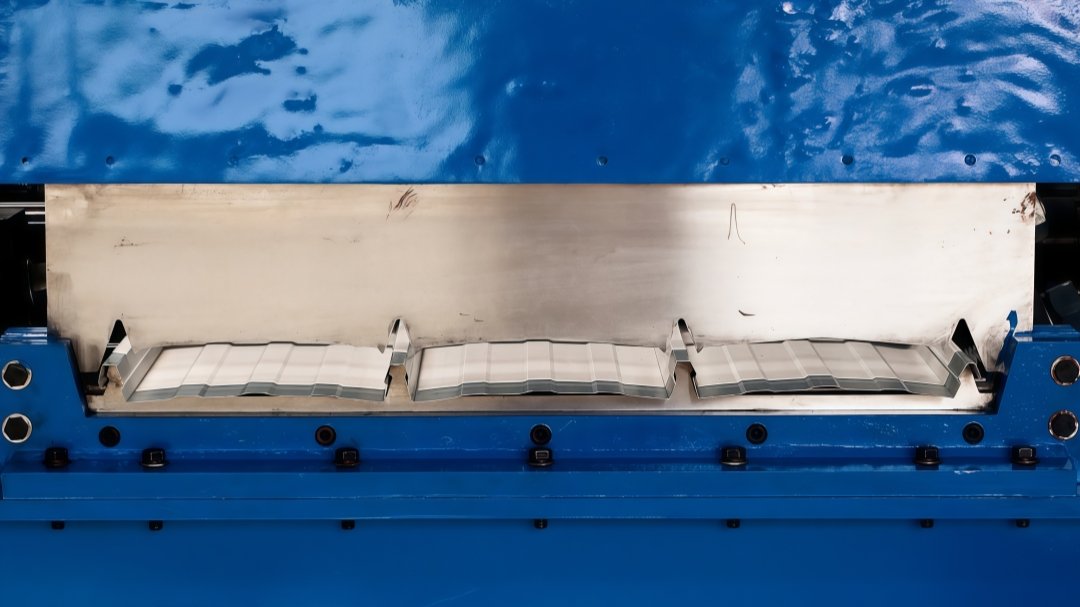

The cutting tools used are made of CR12MOV. Three blades structure with scrap.

This type of clip lock roof panel is mainly used for roofs and walls where performance and appearance requirements are high. It is commonly used in commercial and industrial buildings such as warehouses and factories; public facilities such as airports and stadiums also frequently use it; and it is also chosen for construction projects requiring high-quality roofs or walls.

Reviews

There are no reviews yet.