Formwork and Shuttering Roll Forming Machine

Beenew Steel Formwork and Shuttering Roll Forming Machine has many types to choose. Gear-box transmission type, chain and spocket transmission type?

Description

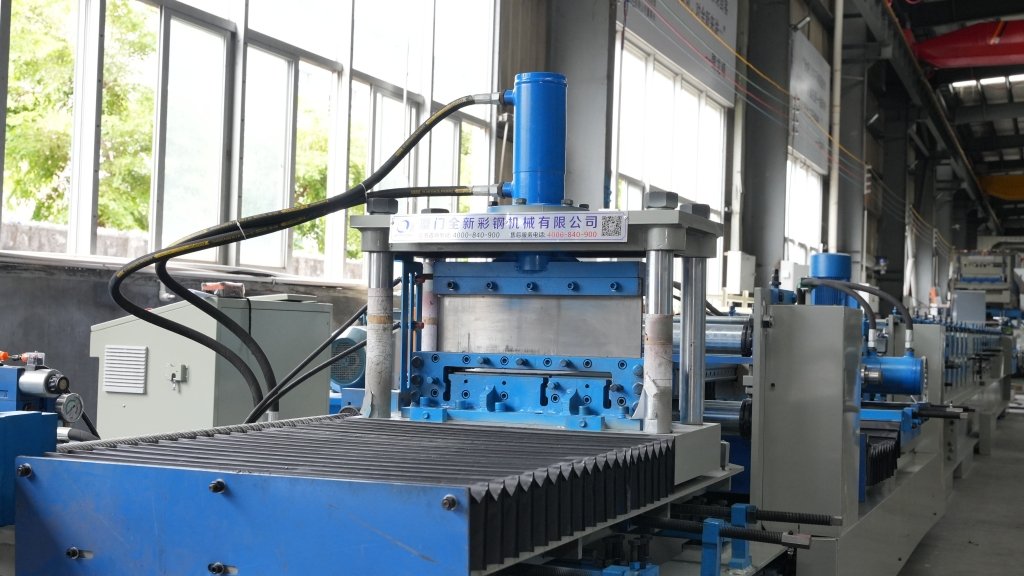

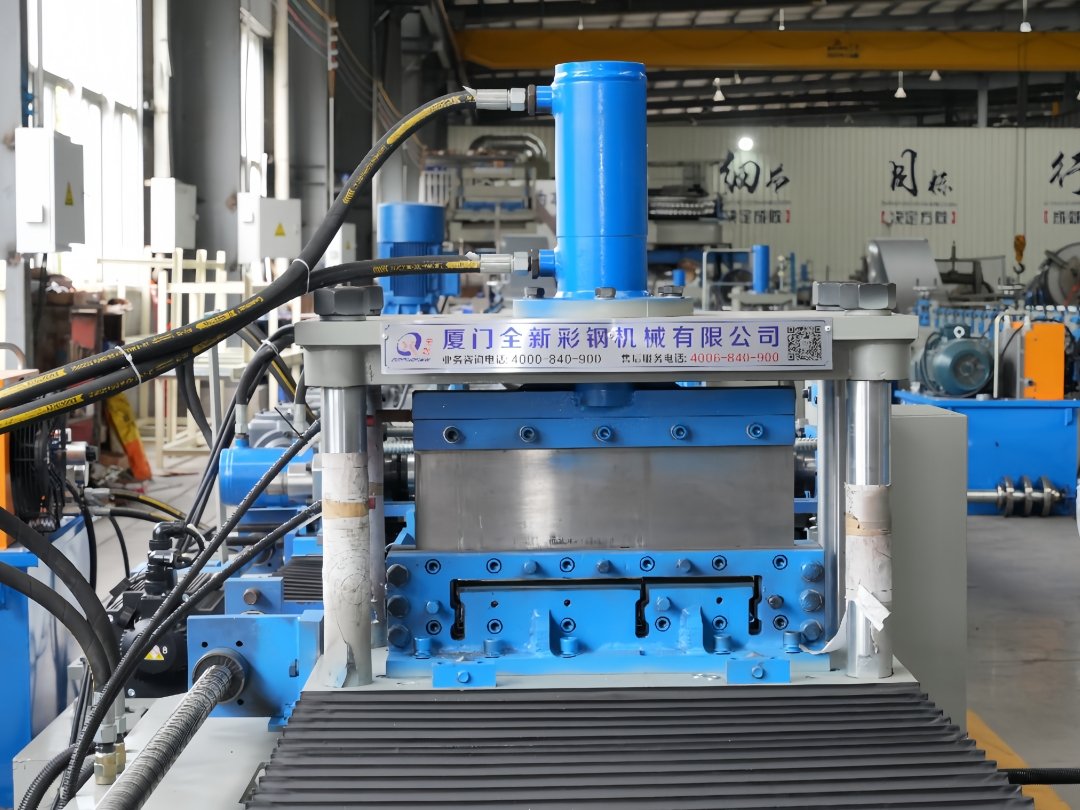

Formwork and Shuttering Roll Forming Machine

1. What is Formwork?

First, it’s crucial to understand the product it makes. Formwork (sometimes called shuttering) is a temporary mold into which fresh concrete is poured to form structural elements like walls, columns, slabs, and tunnels. Modern formwork systems are modular, re-usable panels made primarily of steel or aluminum.

2. The Role of the Roll Forming Machine

This machine is designed to fabricate these complex metal parts. It is a continuous process line that typically includes the following key stations:

a) Un-coiler :

Holds the raw sheet metalto supply material to the machine

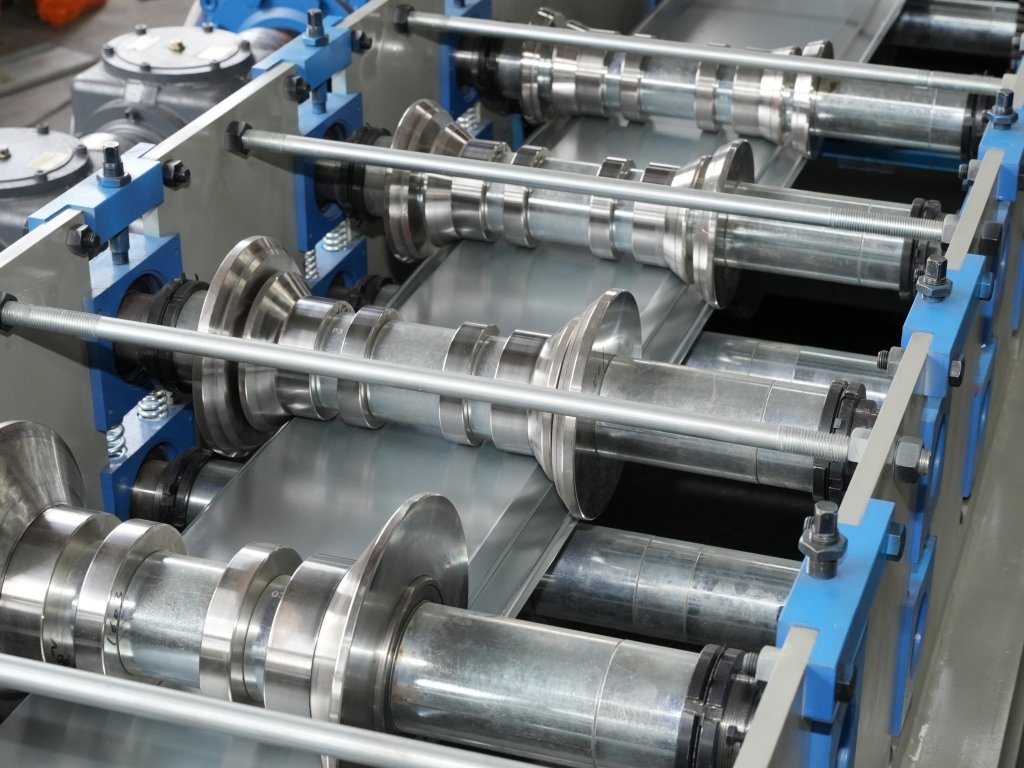

b) Roll Forming Station :

The main part of the machine line. The steel coil enters the machine after several rollers for straightening, and then roll formed by series of paired rollers .Each set of rollers makes a small, incremental bend in the metal.

To form G700 MPA Cold-rolled high-strength steel plate, this machine has 29 stations of rollers which are made from Cr12 Mould Steel and are precision machined inner and outer diameters, and then do carbonitriding heat treatment. These processes make these rollers easy and wear-resistant when processing high-strength steel plates.

This machine uses gearbox transmission. Gearbox transmission provides powerful, stable torque for smooth rolling of heavy-gauge steel, ensuring consistent panel quality with minimal maintenance.

c) Post Non-stop Punching and Cutting Device:

The machine is equipped with a non-sotop punching and shearing device, which means punching and shearing after forming without stopping the machine. It enables seamless synchronization of punching and cutting, which streamlines the workflow and minimizes material waste.

3. Key Advantages of Using This Machine

High Speed & Mass Production: It can produce components continuously at speeds of 10-30 meters per minute, making it vastly faster than manual fabrication.

Exceptional Consistency & Quality: Every single piece is identical, which is critical for ensuring formwork panels fit together perfectly on the construction site, creating seamless concrete surfaces.

Material Efficiency: It minimizes waste by using coiled steel and cutting to exact lengths.

Labor Savings: The automation drastically reduces the need for manual labor and welding.

Strength and Precision: The cold-forming process work-hardens the steel, and the CNC-controlled punching ensures hole accuracy to within fractions of a millimeter.

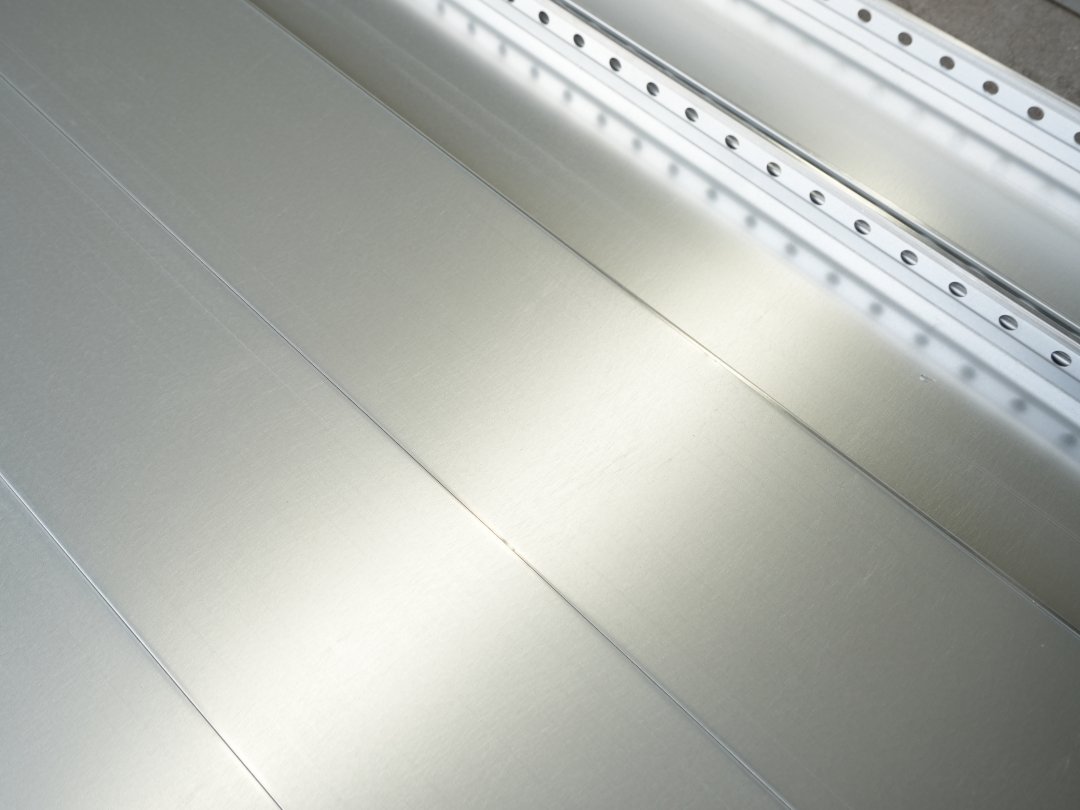

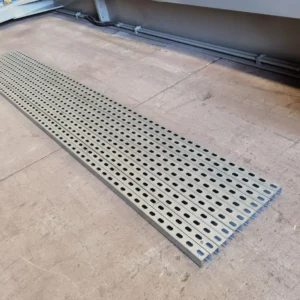

4. What Does the Final Product Look Like?

The machine doesn’t produce a complete, ready-to-use formwork panel. It produces the major metal components that are then assembled (often by welding or bolting) into the final product. It’s a large, flat panel with upturned edges and precisely placed holes (the face).

Reviews

There are no reviews yet.