Hat Channel Roll Former India

Beenew hat channel roll former is used to produce hat purlin, also called “Omega” purlin. These hat purlins are widely used in construction and other industries .

Description

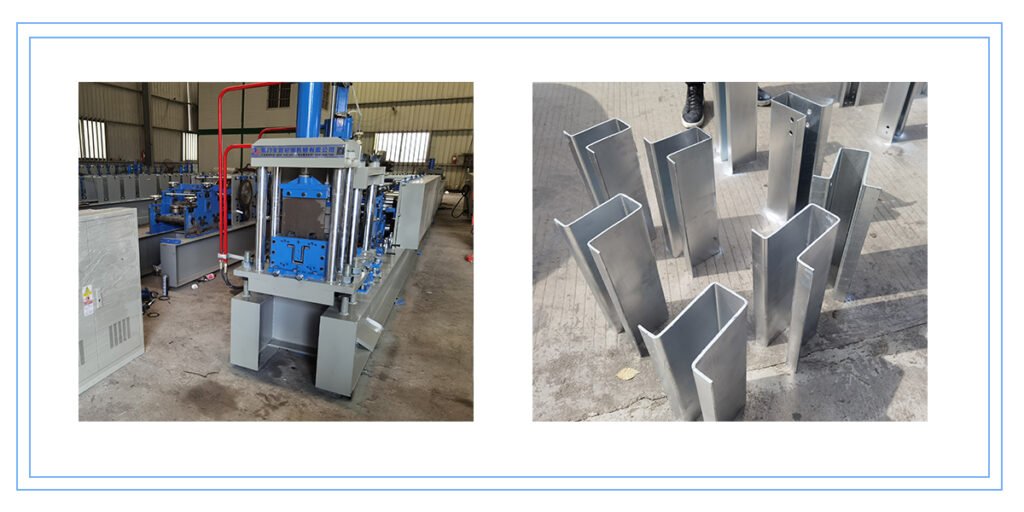

Top hat roll forming machine

Beenew hat channel roll former is used to produce hat purlin, also called “Omega” purlin. These hat purlins are widely used in construction and other industries . They serve as structural support or framing elements in numerous applications, including inner wall cladding, ceilings, and roofs. And with the rise of the photovoltaic industry, hat purlins also are used as beams and columns for photovoltaic mounts.

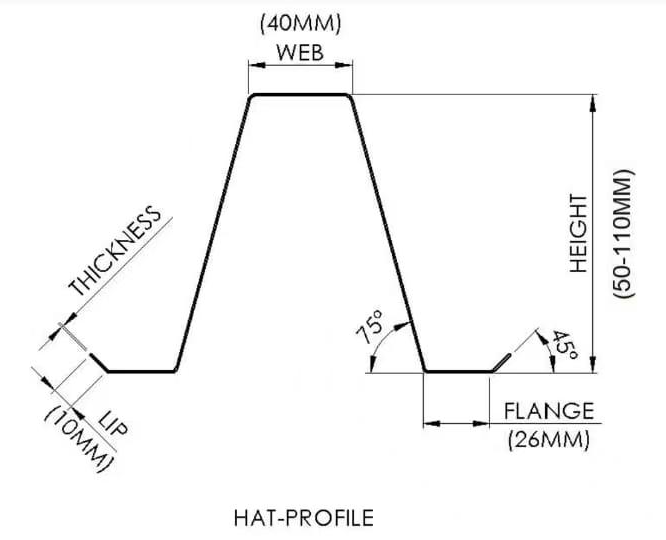

This hat channel roll former is special manufactured for solar beams and columns, the hat channel is 40mm of web and can change size automatically in height from 50mm to 110mm. This range can meet most of the needs of PV mounting customers especially in India PV solar industry.

Profile drawing

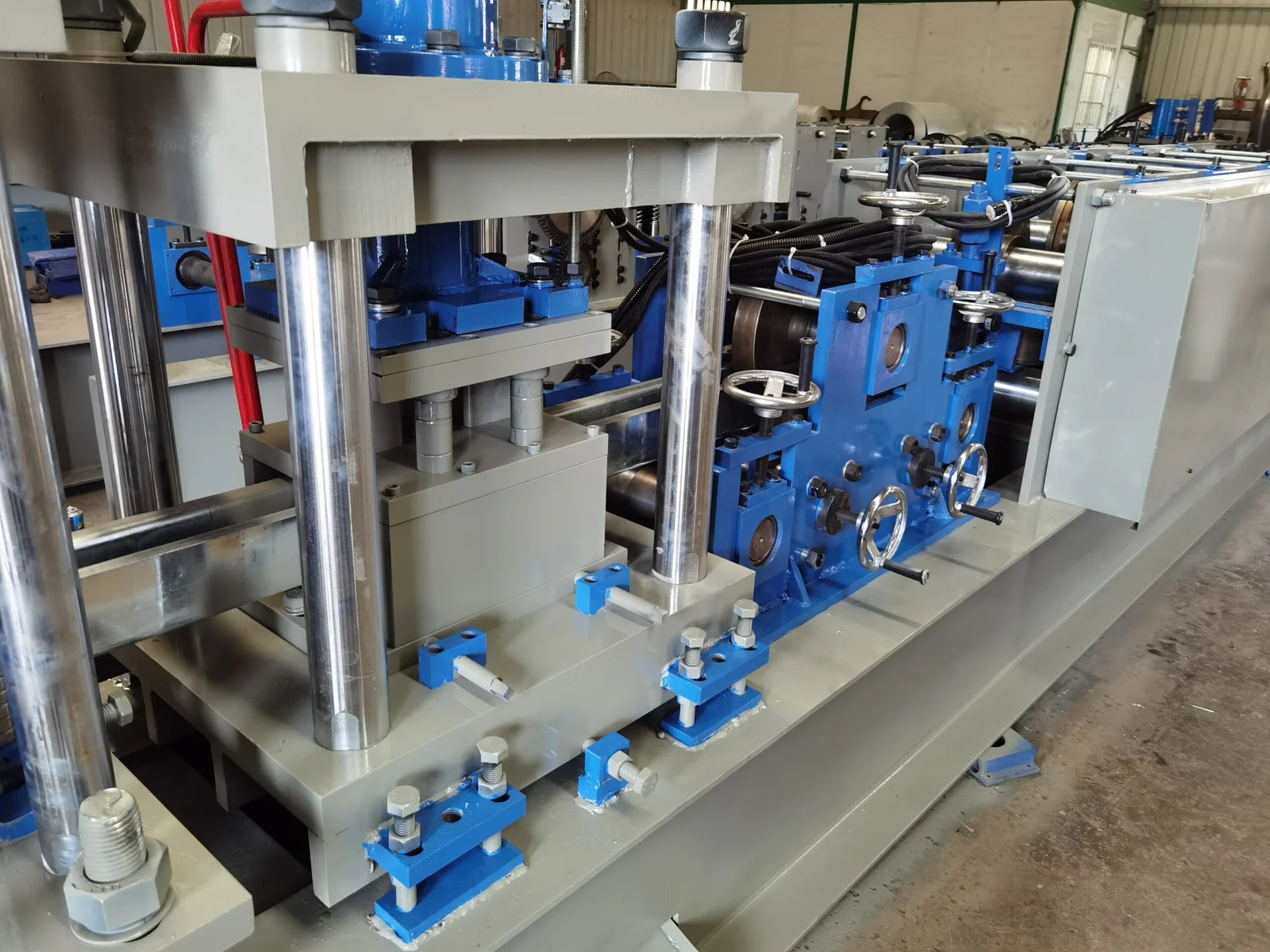

As a framing or support component, hat channel profile should be of strength and stability. So the steel coils used to produce PV hat channel are of good quality and high strength. Beenew hat channel roll former is designed to form high quality galvanized steel coils. This requires purlins of high material quality and strength. So the whole machine is of high parameters. Machine frame is H350 steel, and all rollers and shafts are fine processed and hard chrome coated. There is totally 16 steps and can form material thickness from 0.8mm to 2.0mm steel coil.

The whole roll former line is mainly composed of a 3-ton simple unloading machine, a guide device, a forming main machine, a punching device, a hydraulic forming post-shear device, a finished product run out table , a hydraulic station, a computer control cabinet and other components.

Hat Channel Roll Forming Machines are essential assets in numerous production lines, capable of fabricating hat channels with uniform dimensions at remarkable speeds. The design and functionality of these machines can differ based on the manufacturer and the specific application needs.

Hat channels are typically crafted from thin – gauge metals, including steel and aluminum. The thickness is determined by the intended use and load – bearing requirements.

In construction and industrial fields, hat channels have a broad range of uses. They are frequently utilized for wall framing, ceiling support, creating sub – structures for drywall or insulation, and reinforcing building components.

Due to their thin – gauge build, hat channels are relatively light compared to solid beams and other framing materials, facilitating easy handling and installation.

Renowned for their durability, hat channels can resist bending and warping under load, making them ideal for scenarios where structural stability is of utmost importance.

Available in various lengths, hat channels can be cut on – site to the required size or ordered in custom lengths to meet project – specific demands.

They can be attached to walls, ceilings, or other surfaces using screws, bolts, or other fasteners. Additionally, they can serve as a mounting base for different fixtures and equipment.

Insulation Properties: Hat channels are sometimes integrated into soundproofing or thermal insulation systems. When combined with insulation materials, they create an air gap that improves sound and thermal insulation.

Hat channel profiles come in a variety of sizes and configurations to satisfy different structural and architectural requirements. Their specific dimensions and thickness depend on factors such as load – bearing capacity and local building codes.

Hat channel profiles are versatile, cost – efficient, and widely adopted in the construction industry for framing and support. They offer an effective way to build stable structures while optimizing material usage.

Reviews

There are no reviews yet.